Troubleshooting Tips for Omron PLC Systems

Table of Contents

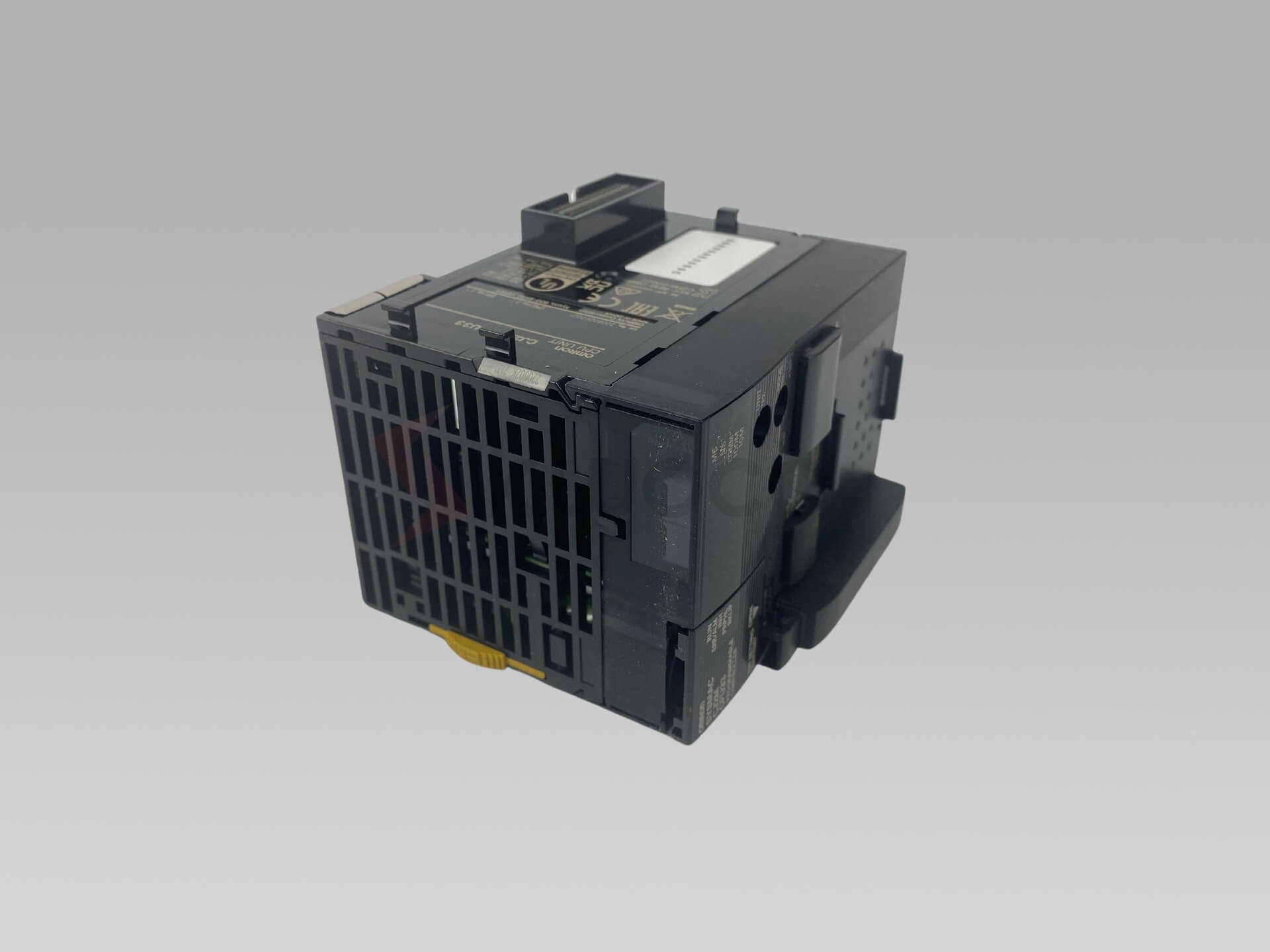

1. Understand the Basics of Omron PLC Systems

Before diving into troubleshooting, it’s essential to have a solid understanding of how Omron PLCs operate. Omron PLCs are designed to control machinery and processes by receiving input signals, processing them through a programmed logic, and generating output signals to control devices. Familiarize yourself with the following components:

- CPU Unit: The brain of the PLC that executes the program.

- Input/Output (I/O) Modules: These handle communication between the PLC and external devices.

- Power Supply Unit: Provides power to the PLC system.

- Programming Software: CX-Programmer or Sysmac Studio for Omron PLCs.

Having a clear understanding of these components will help you identify where issues might arise.

2. Check Power Supply Issues

One of the most common problems in PLC systems is power-related issues. If your Omron PLC is not functioning, start by checking the power supply:

- Verify Voltage Levels: Ensure the power supply unit is receiving the correct voltage. Omron PLCs typically operate on 24V DC or 100-240V AC.

- Inspect Fuses and Circuit Breakers: Blown fuses or tripped breakers can cut off power to the PLC.

- Check Connections: Loose or corroded wiring can disrupt power delivery.

If the power supply is functioning correctly, move on to other potential issues.

3. Inspect I/O Modules

Input and output modules are critical for the PLC’s interaction with external devices. If the PLC is not responding as expected, the issue might lie in the I/O modules:

- Check LED Indicators: Omron PLCs have LED indicators on I/O modules that show the status of inputs and outputs. If an LED is off when it should be on, there may be a wiring or module issue.

- Test Input Devices: Use a multimeter to verify that input devices (e.g., sensors, switches) are sending the correct signals to the PLC.

- Inspect Output Devices: Ensure that output devices (e.g., relays, motors) are functioning correctly and receiving signals from the PLC.

4. Review the PLC Program

Programming errors are another common source of issues in PLC systems. If the hardware components are functioning correctly, the problem might be in the program:

- Check for Syntax Errors: Use the programming software to scan for syntax errors in the ladder logic or structured text.

- Verify Logic Flow: Ensure the program logic aligns with the intended operation. For example, confirm that timers, counters, and conditional statements are set up correctly.

- Monitor Program Execution: Use the software’s monitoring feature to observe the program’s execution in real-time. This can help identify where the logic might be failing.

5. Address Communication Problems

Omron PLCs often communicate with other devices, such as Human-Machine Interfaces (HMIs), sensors, or other PLCs. Communication issues can disrupt the entire system:

- Check Communication Cables: Inspect cables for damage or loose connections.

- Verify Communication Settings: Ensure that the baud rate, parity, and other communication parameters match between the PLC and connected devices.

- Test Network Connections: If the PLC is part of a network, use diagnostic tools to check for network issues, such as IP conflicts or signal interference.

6. Monitor Error Codes and Diagnostics

Omron PLCs are equipped with diagnostic features that can help identify issues:

- Check Error Codes: If the PLC displays an error code, refer to the user manual to understand its meaning and recommended actions.

- Use Diagnostic Tools: Omron’s programming software includes diagnostic tools that can provide detailed information about the system’s status and potential issues.

7. Preventative Maintenance

Regular maintenance can prevent many common issues with Omron PLC systems:

- Clean the PLC and Components: Dust and debris can cause overheating or short circuits.

- Tighten Connections: Periodically check and tighten all electrical connections.

- Update Firmware: Ensure the PLC’s firmware is up to date to benefit from the latest features and bug fixes.

8. Consult Documentation and Support

If you’re unable to resolve the issue, consult the following resources:

- User Manuals: Omron provides detailed manuals for their PLCs, which include troubleshooting guides.

- Online Forums and Communities: Engage with other professionals who use Omron PLCs to share insights and solutions.

- Omron Technical Support: Reach out to Omron’s customer support for expert assistance.

Conclusion

Troubleshooting Omron PLC systems requires a systematic approach, starting with the basics and gradually narrowing down the potential causes of the issue. By understanding the system’s components, checking power supplies, inspecting I/O modules, reviewing the program, and utilizing diagnostic tools, you can effectively resolve most problems. Additionally, regular maintenance and staying informed about best practices will help ensure your Omron PLC system operates smoothly and efficiently.

By following these troubleshooting tips, you’ll be well-equipped to handle common issues and keep your industrial processes running without unnecessary downtime. Remember, when in doubt, consult the documentation or seek support from Omron’s technical team.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Understanding PLC System Integrators: The Key to Effective Control System Integration

In the rapidly advancing world of industrial automation, the role of PLC system integrators has become more critical than ever. If you’re looking to optimize your operations, reduce downtime, and increase productivity, understanding what PLC system integrators do is essential. This article will guide you through the importance of control system integration and how PLC system integrators can transform your business processes.

VFD vs VSD: Understanding Key Differences in Motor Control

Are you confused about the difference between Variable Frequency Drives (VFDs) and Variable Speed Drives (VSDs)? This comprehensive guide will clarify these essential motor control technologies, helping you make informed decisions for your industrial applications.

Understanding PLCs: Uses of Programmable Logic Controllers

Programmable Logic Controllers (PLCs) have become an integral part of modern industrial automation. If you’ve ever wondered how complex machinery and production lines perform tasks with such precision, the answer lies in the use of PLCs.