PLC Output Types: Essential Guide for Automation Engineers

Whether you’re a seasoned automation professional or just starting your journey, this article will provide valuable insights into PLC output technologies.

Table of Contents

What Are the Main Types of PLC Outputs and How Do They Work?

PLC outputs come in several varieties, each designed for specific applications and requirements. The three main types are:

- Relay Outputs: Traditional electromechanical switching devices

- Transistor Outputs: Solid-state switching for DC applications

- Triac Outputs: Solid-state switching for AC applications

Relay outputs are the most versatile, as they can handle both AC and DC loads. A typical relay output module contains physical coils and relay contacts, operated by applying voltage to the relay coil. For example, the Allen-Bradley 1756-OW16I has 16 individual relay outputs, making it suitable for various industrial applications.

What Are the Key Differences Between Solid-State and Relay Outputs?

The choice between solid-state and relay outputs depends on several factors:

| Feature | Solid-State Outputs | Relay Outputs |

|---|---|---|

| Switching Speed | Fast (microseconds) | Slow (milliseconds) |

| Lifespan | Long (no moving parts) | Limited (mechanical wear) |

| Voltage Range | Limited to AC or DC | Both AC and DC |

| Cost | Higher initial cost | Lower initial cost |

| Maintenance | Minimal | Regular maintenance required |

One advantage of relay outputs is their voltage independence, allowing them to switch both AC and DC loads without requiring separate modules. However, solid-state devices offer better reliability and longer service life due to the absence of moving parts.

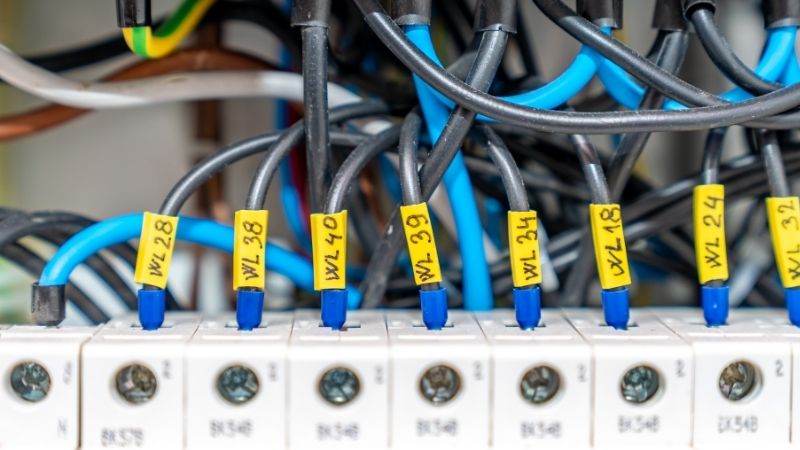

How Do Digital Output Modules Interface with Industrial Equipment?

Digital output modules serve as the interface between the PLC program and external devices. These modules can control:

- Motor starters

- Solenoid valves

- Indicator lights

- Contactors

- Other digital or discrete devices

The output module operates based on decisions made by the PLC program, converting these decisions into physical actions through voltage or current signals. For instance, you can use one output to operate an AC load and another output to control a DC load, providing flexible control options.

What Are the Important Considerations for PLC Output Selection?

When selecting PLC outputs, consider these crucial factors:

- Voltage and Current Ratings

- Operating voltage requirements

- Maximum current draw

- Surge protection needs

- Switching Requirements

- Frequency of switching

- Load type (resistive, inductive, capacitive)

- Response time requirements

- Environmental Conditions

- Operating temperature

- Humidity levels

- Electrical noise

What Are Common Troubleshooting Issues with PLC Outputs?

Understanding common output problems helps maintain system reliability:

- Short circuit protection of outputs

- Voltage drops across long distances

- Interference from nearby equipment

- Output module failure symptoms

- Proper grounding techniques

Frequently Asked Questions

A PLC output module converts program decisions into physical actions by controlling external devices through electrical signals.

The choice depends on your load requirements and system design. Sinking outputs are common in North America, while sourcing outputs are prevalent in Europe.

Transistor outputs offer faster switching speeds, longer lifespan, and no mechanical wear, making them ideal for high-speed applications.

Relay outputs are preferred when voltage flexibility is needed or when complete electrical isolation is required between the control and load circuits.

Use proper surge protection, ensure correct wiring, maintain proper load ratings, and implement adequate cooling measures.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- PLC outputs come in three main types: relay, transistor, and triac

- Each output type has specific advantages and applications

- Proper selection depends on load requirements and environmental conditions

- Regular maintenance and monitoring ensure reliable operation

- Protection measures are essential for long-term reliability

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.

What is Ethernet/IP? Understanding the Industrial Protocol

In today’s rapidly evolving industrial landscape, understanding EtherNet/IP (Industrial Protocol) is crucial for anyone involved in industrial automation and IIoT implementations.

What is the Most Popular Allen-Bradley PLC?

What is the Most Popular Allen-Bradley PLC? If you’re in the automation industry, you’ve probably heard of Allen-Bradley PLCs. They