Are Servo Motors AC or DC? Understanding the Differences

Table of Contents

Understanding Servo Motors

Servo motors are essential components in modern automation. They provide precise control of angular or linear position, velocity, and acceleration.

This precision makes them invaluable in industries such as robotics, manufacturing, aerospace, and more. But to leverage their capabilities fully, it’s important to understand the types of servo motors available and how they differ.

AC vs. DC Servo Motors

At the most fundamental level, servo motors can be classified into two categories based on the type of current they use: Alternating Current (AC) and Direct Current (DC) servo motors. Both types serve the same basic function but have different characteristics, advantages, and ideal use cases.

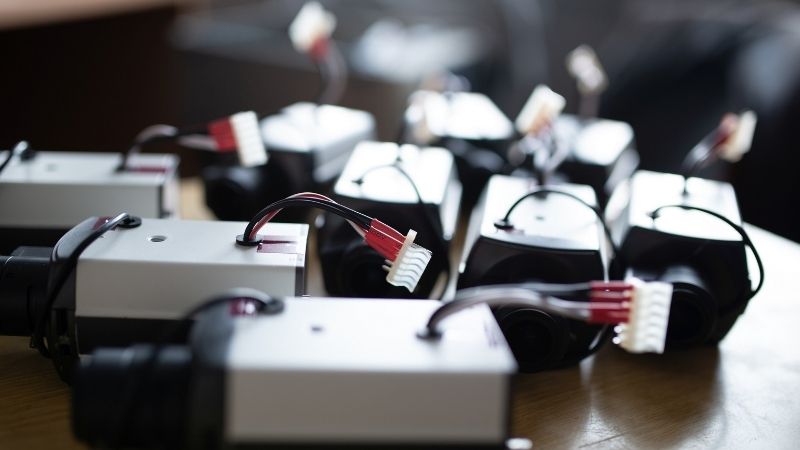

DC Servo Motors

Construction and Operation

DC servo motors are powered by direct current. They typically consist of a stator (the stationary part), a rotor (the rotating part), brushes, and a commutator. The brushes and commutator work together to reverse the direction of current in the rotor windings, allowing the motor to produce continuous rotational motion.

Advantages of DC Servo Motors

- Simplicity of Control: DC servo motors are relatively straightforward to control. Adjusting the input voltage directly influences the motor speed, making them suitable for applications requiring simple speed control.

- High Starting Torque: They provide significant torque at low speeds, which is beneficial for applications that need strong starting power.

- Cost-Effective: Generally, DC servo motors are less expensive upfront compared to their AC counterparts, making them attractive for budget-conscious projects.

Disadvantages of DC Servo Motors

- Maintenance Requirements: The brushes and commutator are subject to wear and tear due to friction. This necessitates regular maintenance and eventual replacement of these components.

- Limited Speed Range: Mechanical commutation limits the maximum speed of DC servo motors. At high speeds, the brushes can cause sparking and excessive heat.

- Efficiency: They are typically less efficient than AC motors due to energy losses in the brushes and commutator.

Applications of DC Servo Motors

DC servo motors are ideal for applications where precise speed control is needed at lower power levels. Common uses include:

- Small robotics

- Conveyor systems

- Printing presses

- Packaging machines

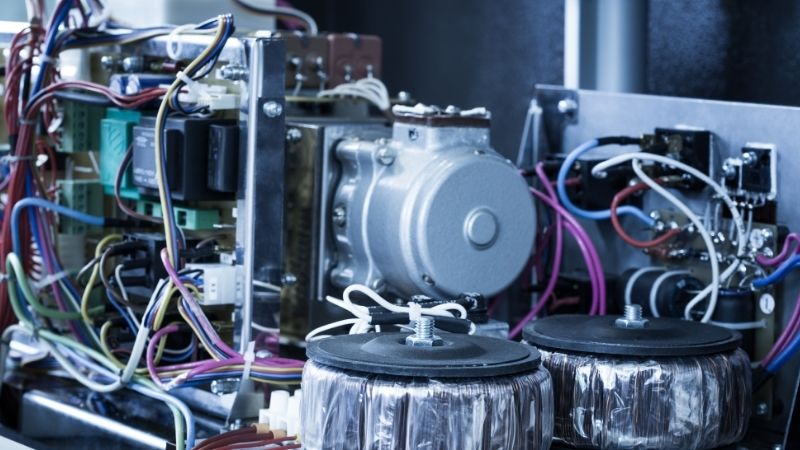

AC Servo Motors

Construction and Operation

AC servo motors operate on alternating current. They generally use either synchronous or induction (asynchronous) motor designs. In synchronous AC servo motors, which are commonly used, the rotor is equipped with permanent magnets and rotates in sync with the stator’s rotating magnetic field.

Advantages of AC Servo Motors

- Low Maintenance: Without brushes and a commutator, AC servo motors have fewer parts that wear out, reducing maintenance needs.

- Higher Speeds and Efficiency: They can operate at higher speeds and are more energy-efficient, which is beneficial for continuous operation and high-speed applications.

- Better Control and Precision: AC servo motors offer superior control over position, speed, and torque, making them suitable for complex and precision-dependent tasks.

Disadvantages of AC Servo Motors

- Complex Control Systems: They require sophisticated electronic controllers, such as variable frequency drives and servo drives, which can increase the system’s complexity and cost.

- Higher Initial Cost: The advanced components and technology used in AC servo motors make them more expensive upfront compared to DC servo motors.

Applications of AC Servo Motors

AC servo motors are preferred in high-performance and precision applications, such as:

- Industrial robotics

- CNC machinery

- Aerospace systems

- Automatic door openers

- High-speed packaging equipment

Key Differences Between AC and DC Servo Motors

1. Power Source

- AC Servo Motors: Operate on alternating current provided by the power grid or generated by inverters.

- DC Servo Motors: Use direct current, often supplied by batteries or a DC power supply.

2. Control Complexity

- AC: Require advanced controllers to manage frequency, voltage, and current for precise operation.

- DC: Easier to control with simpler circuitry due to the direct relationship between voltage and speed.

3. Maintenance

- AC: Lower maintenance due to the absence of brushes and commutators.

- DC: Higher maintenance because brushes and commutators are prone to wear.

4. Efficiency and Performance

- AC: Generally more efficient and capable of higher speeds and better performance in dynamic applications.

- DC: Less efficient at high speeds but excellent for applications requiring high starting torque.

5. Cost

- AC: Higher initial cost due to complex controllers but can be more cost-effective over time with reduced maintenance.

- DC: Lower initial cost but may incur higher maintenance expenses over the motor’s lifespan.

Choosing the Right Servo Motor for Your Application

Selecting between an AC and DC servo motor depends on various factors specific to your project needs.

Considerations:

- Application Requirements: High-speed, high-precision applications often benefit from AC servo motors. For simple, low-speed tasks, DC servo motors might suffice.

- Budget Constraints: If upfront cost is a concern and the application doesn’t demand high performance, a DC servo motor could be more economical.

- Maintenance Capability: If you prefer minimal maintenance, investing in an AC servo motor can save time and costs in the long run.

- Control System Complexity: Assess your ability to implement and manage sophisticated control systems. AC servo motors require more advanced electronics.

Example Scenarios:

- Industrial Automation: In a factory setting with automated machinery requiring precise control and high reliability, AC servo motors are typically the go-to choice.

- Educational Robotics: For teaching purposes or hobbyist projects where budgets are limited, and the requirements are less demanding, DC servo motors are practical.

My Experience with Clients

I’ve worked with numerous clients across North America and Europe, each with unique challenges and requirements.

Case Study 1: Automotive Manufacturing

A client in the automotive industry needed motors for robotic arms that assemble car components. Precision and reliability were paramount. We recommended AC servo motors due to their superior control and low maintenance. The result was increased efficiency and reduced downtime on their assembly lines.

Case Study 2: Packaging Industry

Another client involved in packaging required motors for conveyor belts. The application didn’t demand high precision, but they needed high starting torque and cost-effectiveness. DC servo motors were an excellent fit here, providing the necessary performance without unnecessary expense.

How Kwoco Can Assist You

At Kwoco, we pride ourselves on being stockists of a vast array of industrial automation products. With over 30 million products in stock, including both AC and DC servo motors from renowned brands like Omron, Mitsubishi, Schneider, Panasonic, and Siemens, we’re equipped to meet your needs promptly.

Our Services Include:

- One-Stop Purchasing: Simplify your procurement process by sourcing all your components from one place.

- Technical Support: Our team provides expert guidance to help you select the right products and troubleshoot any issues.

- Solution Support: We assist in developing tailored solutions that fit your project’s specifications.

- Fast Quotation and Shipment: Time is of the essence, and we ensure quick turnaround times to keep your projects on schedule.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servos– in stock, ready now!

Conclusion

If you’re still unsure about which servo motor is right for your application, I’m here to help. At Kwoco, we believe in building lasting relationships with our clients by providing exceptional service and support.

Feel free to reach out to me or any member of our team. We’re more than happy to answer your questions, provide detailed product information, and offer technical assistance.

Looking for new, original Servos for your projects? At Kwoco, we stock the latest Servos from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is a Timer in PLC, and How Does it Work?

What is a Timer in PLC, and How Does it Work? In the world of industrial automation, time is everything.

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.

PLC Troubleshooting Guide: Essential Tips and Tricks

Programmable Logic Controllers (PLCs) are essential in today’s industrial automation. They act as the brain of the control system, ensuring machines and processes run smoothly. But what happens when things go awry? This comprehensive guide will help you troubleshoot PLC problems effectively, minimizing downtime and keeping your operations efficient.