What is a Timer in PLC, and How Does it Work?

- kwoco-plc.com

- September 7, 2024

- 5:37 am

In the world of industrial automation, time is everything. Every process requires precise timing to ensure smooth operations and efficiency. If you’re in the industrial automation field like me, you know how crucial PLC timers are to maintaining this precision. But what exactly is a timer in PLC, and why is it so important?

A timer in a PLC (Programmable Logic Controller) is a software function that helps manage time-based events in automation processes. Simply put, a timer waits for a set period before performing an action, much like the timer on your microwave but integrated into highly complex industrial processes.

Timers are essential to controlling sequences, delaying signals, or creating repetitive actions. Without them, many industrial operations would struggle to maintain accuracy.

Table of Contents

Why Are Timers So Important in PLCs?

In an industrial environment, precise timing is required to ensure machines and processes function correctly. Take, for example, an automated conveyor belt. You may want it to stop for a few seconds at each workstation, or you might want it to turn off after a set period if a sensor detects no activity. In both cases, a timer is your best friend.

Timers help control these delays, ensuring that everything operates in sync and nothing gets out of order. The success of your automation projects can depend on how well you understand and use these timers.

Types of Timers in PLC

- On-Delay Timer: This is the most commonly used timer. It starts counting when the input signal is ON and delays the action for a predefined period. For example, when a machine needs to wait for 5 seconds before it starts, the on-delay timer is used.

- Off-Delay Timer: This timer activates as soon as the input signal turns OFF, maintaining the output ON for a set time before turning off. It’s handy when you need a process to continue for a while after an input is disabled.

- Retentive Timer: The retentive timer stores the current time and resumes from that point when the input signal turns on again. This type of timer is useful for processes that may start and stop intermittently but need to continue from where they left off.

How Are Timers Used in Real-World Applications?

In my experience at Kwoco, we see timers used across many industrial control processes. Here’s a quick example: imagine a filling machine that needs to open a valve for 5 seconds to fill a container. An on-delay timer would ensure that the valve opens and stays open for the correct amount of time before shutting.

Another example is in motor control. You might want a motor to keep running for a few seconds after a switch is turned off. Using an off-delay timer allows you to control this delay effectively, ensuring that your machine continues running smoothly even after the command to stop has been given.

How Do You Program a Timer in PLC?

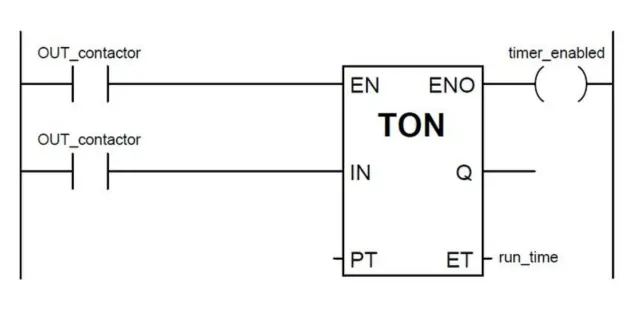

Programming a timer in a PLC is relatively straightforward, but it requires some expertise. You would typically use ladder logic, which is the most common programming language in industrial automation. In ladder logic, timers are represented as blocks within a sequence of commands.

For example, if you’re programming an on-delay timer, you’d insert the timer function into the logic, set your delay time (e.g., 10 seconds), and link it to the corresponding inputs and outputs. Once the input is activated, the timer starts counting down, and when the time expires, the output action is triggered.

You can also combine timers with other logic blocks for more complex processes. In the end, it’s all about finding the right balance to ensure your system runs flawlessly.

What Are the Key Challenges in Using PLC Timers?

Timers are incredibly useful, but they are not without challenges. One common issue is the accuracy of the timing, especially in environments where you need millisecond precision. Delays in inputs, noise in the signals, or even minor software glitches can affect the accuracy of the timer.

Another challenge comes with the use of retentive timers. These can be tricky, especially if the machine is restarted or stops frequently. You must be sure that the timer starts and stops correctly, or it could cause unintended delays in your process.

How to Troubleshoot Timer Issues in PLC?

Troubleshooting timer issues can be a pain, but with a bit of patience and the right approach, you can easily get things back on track. Always start by checking the ladder logic and verifying that the timer is programmed correctly. Is the delay time set appropriately? Are the inputs and outputs correctly wired?

Next, check the hardware. Faulty wiring, poor signal quality, or a defective PLC can all cause timing issues.

Lastly, always have backup copies of your program. I’ve seen too many engineers forget this and have to start from scratch when something goes wrong.

Conclusion

Timers are essential components of PLC programming and industrial automation. Whether you’re dealing with simple on-off sequences or complex multi-stage processes, timers are your go-to tool for managing delays and ensuring precision in your operations. Understanding how to program, use, and troubleshoot them is vital for any industrial engineer or technician.

At Kwoco, we provide original, high-quality PLCs, HMIs, and other automation products from leading brands like Omron, Mitsubishi, and Schneider. Our extensive stock ensures that you can always get the parts you need with fast shipping, and our technical support team is here to help you implement timers and other functions seamlessly into your automation systems.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

Why Your PLC Needs a Separate Power Supply

Why Your PLC Needs a Separate Power Supply Have you ever wondered why PLC systems often require a separate power

Why Your Business Needs a Variable Frequency Drive

Why Your Business Needs a Variable Frequency Drive When managing industrial operations, optimizing energy efficiency while maintaining performance is crucial.

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.