Step-by-Step Guide to Programming Omron PLCs for Beginners

Table of Contents

What is an Omron PLC?

Omron PLCs are industrial digital computers designed to control manufacturing processes, such as assembly lines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. They are known for their robustness, flexibility, and user-friendly programming environment.

Step 1: Understand the Basics of PLCs

Before diving into programming, it’s crucial to understand the fundamental concepts of PLCs:

- Inputs and Outputs (I/O): PLCs interact with the physical world through inputs (sensors, switches) and outputs (motors, lights).

- Ladder Logic: The most common programming language for PLCs, resembling electrical relay logic diagrams.

- Scan Cycle: PLCs operate in a continuous loop, scanning inputs, executing the program, and updating outputs.

Step 2: Set Up Your Omron PLC

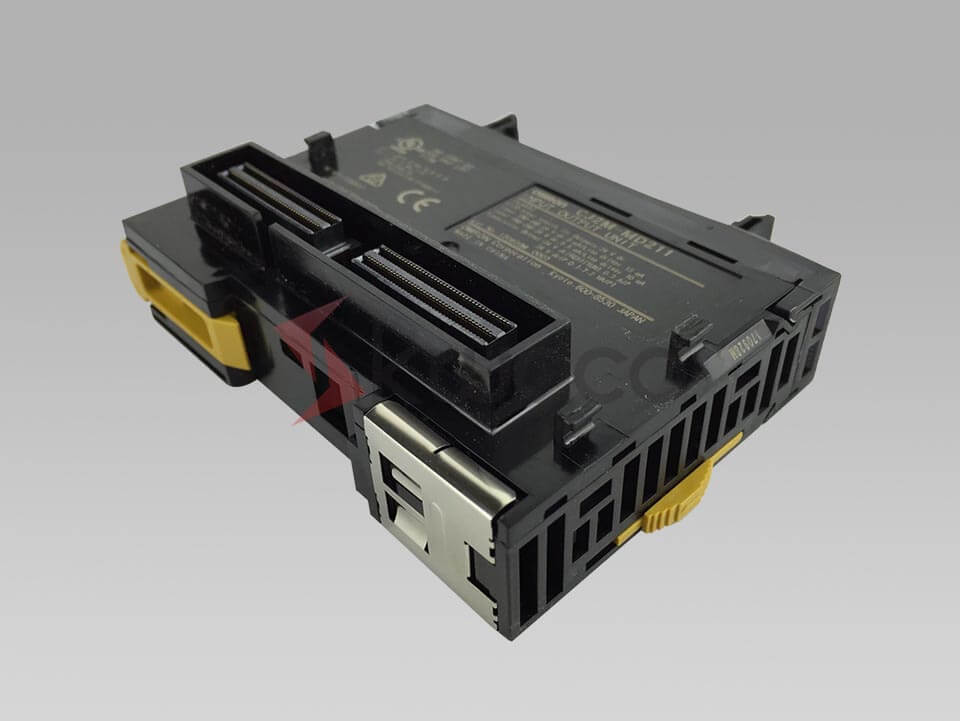

1. Choose the Right Omron PLC Model:

- Omron offers a range of PLCs, from compact models like the CP1 series to more advanced models like the CJ2 series. Select a model that fits your application’s requirements.

2. Install the PLC:

- Mount the PLC in a suitable location, ensuring proper ventilation and protection from environmental factors.

- Connect the power supply, ensuring the voltage matches the PLC’s specifications.

3. Connect I/O Devices:

- Wire the input devices (e.g., sensors, switches) to the input terminals.

- Wire the output devices (e.g., motors, lights) to the output terminals.

Step 3: Install Omron Programming Software

Omron PLCs are programmed using the CX-Programmer software, which is part of the CX-One software suite. Follow these steps to install the software:

Download and Install CX-One:

- Visit the Omron website and download the CX-One software suite.

- Follow the installation wizard to install the software on your computer.

Connect the PLC to Your Computer:

- Use a USB or Ethernet cable to connect the PLC to your computer.

- Ensure the PLC is powered on.

Configure Communication Settings:

- Open CX-Programmer and configure the communication settings to establish a connection with the PLC.

Step 4: Create a New Project

Open CX-Programmer:

- Launch the CX-Programmer software.

Create a New Project:

- Click on File > New to create a new project.

- Select the appropriate PLC model from the list.

Set Up the Project:

- Define the project name and save it in your desired location.

- Configure the I/O settings according to your hardware setup.

Step 5: Write Your First Ladder Logic Program

1. Understand Ladder Logic Basics:

- Ladder logic consists of rungs, each representing a logical operation.

- Inputs are represented by normally open (NO) or normally closed (NC) contacts.

- Outputs are represented by coils.

2. Create a Simple Program:

- Example: Turn on a light when a button is pressed.

- Drag and drop a NO contact from the toolbar to the first rung.

- Assign an input address (e.g., 0.00) to the contact.

- Drag and drop a coil to the same rung.

- Assign an output address (e.g., 100.00) to the coil.

3. Add More Logic:

- You can add more contacts and coils to create complex logic.

- Use timers, counters, and other function blocks to enhance your program.

Step 6: Download the Program to the PLC

Compile the Program:

- Click on Program > Compile to check for errors in your program.

Download the Program:

- Click on Online > Transfer to PLC to download the program to the PLC.

- Ensure the PLC is in Program Mode before downloading.

Switch to Run Mode:

- After downloading, switch the PLC to Run Mode to execute the program.

Step 7: Test and Debug Your Program

Monitor the Program:

- Use the Online Monitoring feature in CX-Programmer to monitor the program’s execution in real-time.

- Check the status of inputs, outputs, and internal variables.

Debugging:

- If the program doesn’t work as expected, use the debugging tools to identify and fix issues.

- Common issues include incorrect addressing, logic errors, or hardware problems.

Step 8: Expand Your Knowledge

Once you’re comfortable with basic programming, explore more advanced features:

- Function Blocks: Reusable code blocks for complex logic.

- Structured Text (ST): A high-level programming language for more complex tasks.

- Networking: Learn how to connect multiple PLCs and devices using Omron’s network protocols.

Conclusion

Programming Omron PLCs may seem daunting at first, but with the right approach and tools, it becomes a manageable and rewarding task. By following this step-by-step guide, you’ll be well on your way to mastering Omron PLC programming. Remember, practice is key—so keep experimenting, learning, and improving your skills.

Whether you’re automating a small machine or an entire production line, Omron PLCs offer the reliability and flexibility you need to succeed in industrial automation.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

How to Adjust a Photoelectric Sensor: Expert Guide

Adjusting a photoelectric sensor might seem complex, but with the right approach, it becomes a straightforward task. Today, I want to share my expertise on how to adjust a photoelectric sensor effectively.

What Are the Three Types of PLC?

What Are the Three Types of PLC? When choosing the right PLC (Programmable Logic Controller) for your application, understanding the

Inductive Sensors: Demystifying the Working Principle of Inductive Proximity Sensors

This article delves into the fascinating world of inductive sensors, explaining how they work, their various types, and their wide-ranging applications in industrial automation. Whether you’re a seasoned engineer or simply curious about these devices, this comprehensive guide will provide valuable insights into the technology that powers numerous industries, making it a worthwhile read for anyone seeking to understand the intricacies of modern sensing solutions.