Troubleshooting Unresponsive Industrial Touch Screen Panels: A Comprehensive Guide

Table of Contents

1. Why is My Industrial Touch Screen Unresponsive?

An unresponsive industrial touch screen can stem from a variety of causes, ranging from simple fixes to more complex hardware or software problems. Understanding these potential causes is the first step toward solving the problem. It’s not uncommon to encounter issues with industrial HMIs.

- Dirt and Debris: The most common culprit is simply a dirty screen. Dust, grease, and other residue can interfere with the touch screen’s ability to accurately register input.

- Calibration Issues: Touch screens rely on precise calibration to translate your touch into the correct action. If the calibration is off, the touch screen may respond inaccurately or not at all.

- Software Glitches: Like any computer, an industrial panel can experience software glitches or errors that cause the touch function to freeze or become unresponsive.

- Hardware Problems: In more serious cases, the touch screen itself may have a hardware fault. This could be due to physical damage, a faulty connection, or component failure.

2. Is it a Hardware or Software Issue Causing an Unresponsive Touch?

Distinguishing between hardware and software issues is crucial for effective troubleshooting. Here’s how to start:

- Observe the Display: Does the display show a clear image? Are there any visible cracks or scratches on the touch screen? A damaged screen suggests a hardware issue.

- Restart the System: A simple restart can often resolve temporary software glitches. If the touch screen works after a restart, the problem was likely software-related. If you have a PLC and are using the touch screen as an interface for it, you may need to restart the PLC as well.

- Check Connections: Inspect the cable connecting the touch screen to the main unit. Ensure it’s securely plugged in and not damaged. A loose or faulty connection can cause an unresponsive touch.

- Enter Safe Mode: Booting the system in safe mode can help determine if a third-party app or driver is causing the issue. If the touch screen works in safe mode, a software conflict is likely the culprit.

3. What Troubleshooting Steps Can I Take for a Resistive Touch Screen?

Resistive touch screens, commonly found in industrial settings due to their durability, work by pressing two layers of material together. Here’s how to troubleshoot them:

- Visual Inspection: Carefully inspect the screen for any visible debris or damage. Even small imperfections can affect the touch screen’s responsiveness.

- Gentle Cleaning: Use a soft, lint-free cloth to gently clean the screen. Avoid using excessive pressure or harsh chemicals, which can damage the resistive layers. Dampen the cloth with a little water to remove any residue on the screen.

- Calibration: Resistive touch screens are more prone to calibration issues. Access the system’s calibration settings and follow the instructions to recalibrate the touch screen. This process usually involves touching specific points on the screen to restore accuracy. You can find the instructions to recalibrate the touch screen on your industrial panel in the device’s manual.

We offer customized solutions that allow you to customize and optimize touch screen performance for specific industrial applications. Proper customization can improve the reliability and accuracy of your industrial touchscreen.

4. What Troubleshooting Steps Can I Take for a Capacitive Touch Screen?

Capacitive touch screens, which rely on electrical conductivity, are increasingly popular. Here’s how to troubleshoot them:

- Clean the Screen Thoroughly: Capacitive touch screens are highly sensitive to dirt and grease. Use a microfiber cloth and a specialized screen cleaner to thoroughly wipe the screen. Ensure the screen is completely dry before testing the touch function.

- Remove Gloves: Capacitive touch screens typically require direct skin contact to function properly. Remove any gloves or other coverings from your hands before attempting to use the touch screen.

- Adjust Sensitivity Settings: Some capacitive touch screens have sensitivity settings that can be adjusted. Check the system’s settings to ensure the sensitivity is properly configured for your environment.

- Software Check: As with resistive screens, software issues may cause unresponsiveness. Try a simple restart to see if that helps and follow the tips from section two for further troubleshooting steps.

5. How Do I Clean an Industrial Touch Screen Properly?

Proper cleaning is essential for maintaining the responsiveness and longevity of your industrial touch screen. Here’s a step-by-step guide:

- Power Down: Turn off the display to avoid accidental input and to make it easier to see dirt and smudges.

- Use a Soft Cloth: Opt for a soft, lint-free cloth, like those used for cleaning eyeglasses. Avoid paper towels or abrasive materials, which can scratch the screen.

- Choose the Right Cleaner: Use a cleaner specifically designed for touch screens or displays. Avoid ammonia-based cleaners, alcohol, and other harsh chemicals.

- Apply Cleaner Sparingly: Dampen the cloth with the cleaner, rather than spraying the cleaner directly onto the screen. This prevents liquid from seeping into the edges of the display.

- Wipe Gently: Wipe the screen gently in a circular motion, avoiding excessive pressure.

- Dry the Screen: Use a dry, lint-free cloth to wipe away any remaining moisture.

Keeping your touch screens clean can help prevent them from becoming unresponsive to touch and solve the problem.

6. How to perform a Recalibration for your Touch Screen?

Recalibration is a crucial step if your touch screen is inaccurate or unresponsive. Each industrial panel has a built-in calibration app or the operating system offers the functionality to perform a recalibration. You can find the specific instructions on how to recalibrate the touch screen in your device’s manual.

Here’s a general guide:

- Access Calibration Settings: Locate the calibration settings on your system. This is typically found in the control panel or settings menu.

- Follow On-Screen Prompts: The calibration process usually involves touching specific points on the screen as prompted. Ensure you touch each point accurately and hold your finger steady.

- Save Calibration Data: Once the calibration process is complete, save the new calibration data.

- Test the Touch Screen: After recalibration, test the touch screen to ensure it is responding accurately.

7. What to Do If Recalibration Doesn’t Solve the Problem?

If recalibration doesn’t restore the touch screen’s functionality, consider these additional steps:

- Check for Driver Updates: Ensure that the touch screen driver is up-to-date. Outdated or corrupt drivers can cause unresponsiveness. Download and install the latest drivers from the manufacturer’s website.

- Reinstall the Driver: If updating the driver doesn’t work, try uninstalling and reinstalling it. This can resolve any conflicts or errors in the driver installation.

- Perform a System Restore: If you suspect a recent software change caused the issue, perform a system restore to revert the system to a previous state.

- Inspect the Touch Screen Controller: Ensure that the touch screen controller board is properly connected and functioning. If the controller board is damaged, it may need to be replaced.

8. Are There Specific Touch Screen Settings That Can Cause Issues?

Yes, certain touch screen settings can affect its performance. Here are a few to check:

- Touch Sensitivity: Adjusting the touch sensitivity can sometimes improve responsiveness. If the sensitivity is too low, the touch screen may not register light touches. If it’s too high, it may register unintended touches.

- Glove Mode: Some touch screens have a “glove mode” that increases sensitivity for use with gloves. Ensure this mode is enabled if you’re using gloves.

- Palm Rejection: Palm rejection prevents the touch screen from registering accidental touches from your palm. If this feature is too sensitive, it may interfere with intentional touches.

9. When Should I Contact the Manufacturer for Industrial Touch Screen Repair?

If you’ve exhausted all troubleshooting steps and the touch screen remains unresponsive, it’s time to consult the manufacturer or seek professional assistance. Here are some signs that indicate a need for professional repair:

- Physical Damage: Visible cracks, scratches, or other physical damage to the screen.

- Hardware Malfunction: Suspected hardware fault based on troubleshooting steps.

- Warranty Coverage: The touch screen is still under warranty.

- Lack of Expertise: You’re uncomfortable performing advanced troubleshooting or repair procedures.

We understand the critical role that industrial automation plays in modern manufacturing. If you are running into touch screen issues, please contact us. Our team of experts is ready to assist you with any questions or concerns.

10. How Can I Prevent Future Touch Screen Unresponsiveness?

Preventing future touch screen unresponsiveness involves a combination of proper maintenance, environmental considerations, and user training:

- Regular Cleaning: Implement a regular cleaning schedule to remove dust, grease, and other contaminants from the screen.

- Environmental Control: Minimize exposure to extreme temperatures, humidity, and static electricity, which can damage the touch screen.

- Proper Handling: Train users to handle the touch screen with care, avoiding excessive pressure or sharp objects.

- Protective Film: Consider using a protective film to shield the screen from scratches and other damage.

- Calibration Maintenance: Periodically check and recalibrate the touch screen to ensure accurate performance.

- Surge Protection: Voltage surges can damage the touch screen. Use surge protectors to protect the equipment from voltage surges.

By implementing these preventive measures, you can extend the lifespan and reliability of your industrial touch screens.

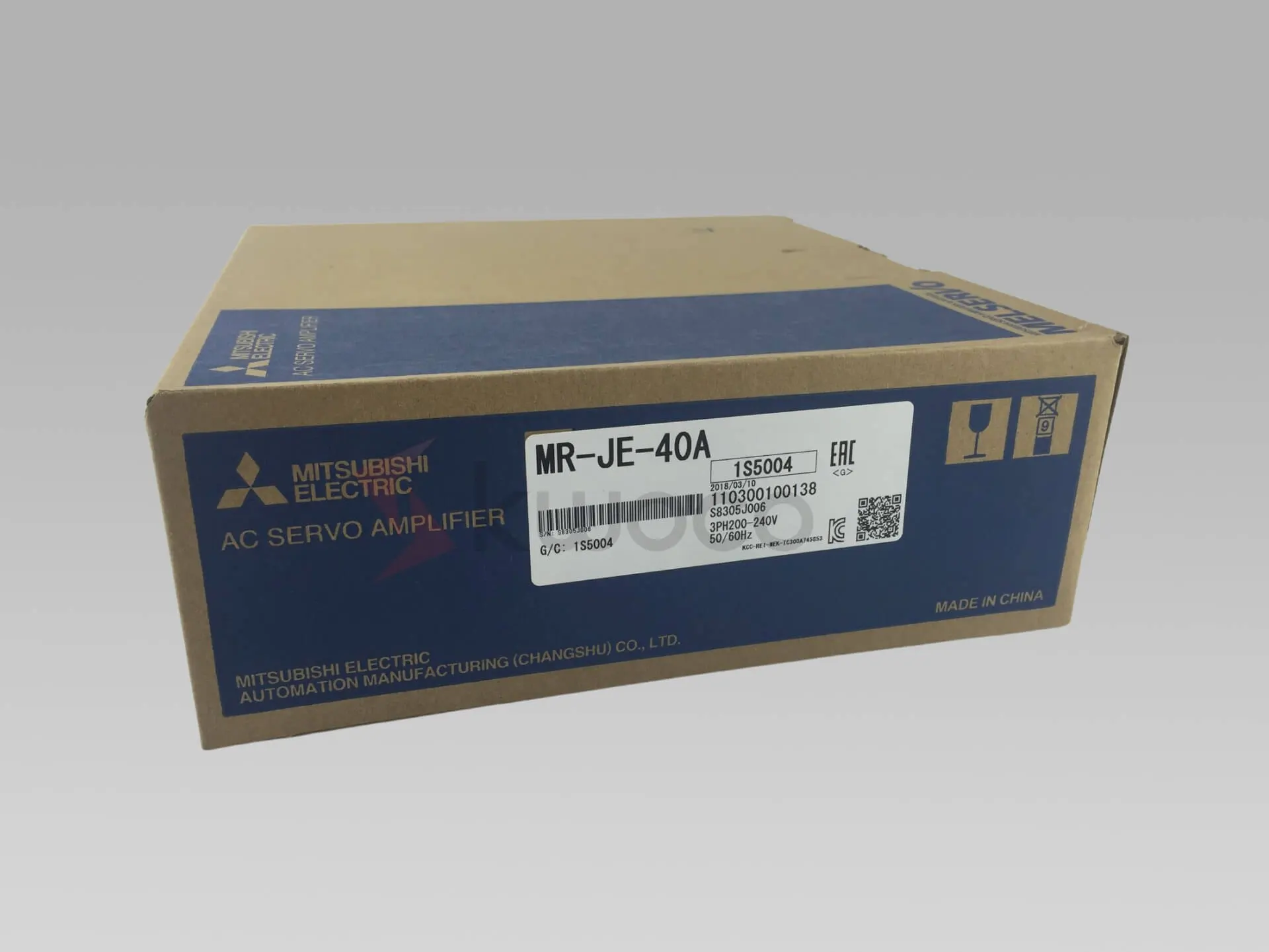

We provide a comprehensive range of industrial control products, including HMIs, PLCs, and servo systems. Our products are designed for reliability and performance in demanding industrial environments.

Frequently Asked Questions

If your touch screen is inaccurate, responds to touches in the wrong location, or doesn’t respond to touches at all, it likely needs recalibration.

Use a soft, lint-free cloth, such as a microfiber cloth. Avoid using paper towels or abrasive materials, which can scratch the screen.

No, avoid using ammonia-based cleaners, alcohol, and other harsh chemicals. These can damage the screen. Use a cleaner specifically designed for touch screens or displays.

Clean your touch screen regularly, depending on the environment. In dusty or dirty environments, clean it daily. In cleaner environments, clean it weekly or as needed.

Static electricity can interfere with the touch screen by disrupting the electrical field used to detect touch. Dry environments, synthetic clothing, and certain materials can increase static electricity.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider HMI – in stock, ready now!

Conclusion

- Start with the basics: Clean the screen thoroughly and check for any visible damage.

- Determine the type of touch screen: Resistive or capacitive, as the troubleshooting steps differ.

- Try recalibration: Follow the instructions to recalibrate the touch screen.

- Check software settings: Adjust touch sensitivity and other relevant settings.

- Update or reinstall drivers: Ensure the touch screen driver is up-to-date and properly installed.

- Seek professional assistance: If all else fails, contact the manufacturer or a qualified technician.

We are industrial automation experts based in Shenzhen. Our company provides industrial control products to machinery and equipment factories, manufacturers, and factory solution companies. If you encounter issues with industrial touch screens or need industrial automation solutions, please contact us. We are here to help.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Complete Guide to Photoelectric Sensor Wiring and Troubleshooting

Are you struggling with photoelectric sensor installation and configuration? This comprehensive guide will walk you through everything you need to know about wiring, setting up, and troubleshooting photoelectric sensors in industrial automation applications.

The Complete Guide to Programmable Logic Controllers (PLCs)

The Complete Guide to Programmable Logic Controllers (PLCs) In the fast-evolving world of industrial automation, Programmable Logic Controllers (PLCs) have

Why Should We Add a Brake Resistor to the Inverter?

Why Should We Add a Brake Resistor to the Inverter? Are you concerned about the performance and longevity of your