PLC Instruction Failures: A Troubleshooting Guide

Table of Contents

Nevertheless, if a PLC instruction falls short, the entire assembly line can grind to a halt, causing incalculable losses. This short article intends to give an extensive exploration of PLC instruction make-up, systematically examine the source of direction failings, and use a clinical, effective set of troubleshooting and resolution methods.

I. The PLC Instruction System: The Cornerstone of Automation Control

Prior to diving into failures, it is essential to initially comprehend the nature of PLC guidelines. A PLC instruction is a collection of commands pre-written into the PLC’s memory, guiding it on just how to reply to input signals and control result tools. A full and powerful direction set is a vital metric for reviewing a PLC’s performance.

1.1 Basic Components of PLC Instructions

Each PLC instruction is made up of several core components that work in harmony to achieve specific control logic:

Function Code: This is the core of the guideline, defining the type of operation to be done, such as ‘ LD’ ( Load), ‘ AND’ ( Logical AND), ‘ OR’ ( Logical OR), and ‘ OUT’ ( Output).

Operand: The target of the guideline’s action, which can be a physical input/output port, an interior register, a timer, or a counter. Common operands consist of:

- ‘I’: Input

- ‘Q’ ( or ‘ O’): Output

- ‘M’: Internal Memory (Memory).

- ‘T’: Timer.

- ‘C’: Counter.

- ‘D’ ( or ‘ DB’): Data Register/Data Block.

Address/Data: Used to pinpoint the specific location of the operand or provide the necessary parameters for the instruction’s execution. For example, I0.0 refers to the 0th point of the first input module. Data can be a constant or a variable stored in a data register.

Execution Condition: The prerequisite for the instruction’s implementation. In ladder logic, this is typically represented by a series of contacts in series or parallel. The instruction is implemented only when these conditions are satisfied.

End Instruction: Marks the end of a program segment or the whole program scan cycle, such as the ‘END ‘direction.

1.2 Comparison of Instruction Types and Application Scenarios

To better recognize the function of different instructions, the complying with table offers a comparative analysis of numerous fundamental logic instructions:

| Instruction/Function Code | Full Name | Functional Description | Typical Application Scenario |

|---|---|---|---|

| LD (Load) | Load | Loads the state of a normally open contact to the top of the logic stack, starting a new line of logic. | Initiating a logical evaluation, such as checking if a start button is pressed. |

| AND (And) | Logical AND | Performs a logical “AND” operation, connecting two or more conditions in series. The result is true only when all conditions are met simultaneously. | Safety interlock control; for instance, a machine can only start when the safety door is closed and the emergency stop is not activated. |

| OR (Or) | Logical OR | Performs a logical “OR” operation, connecting two or more conditions in parallel. The result is true if at least one condition is met. | Multi-point start control, allowing a machine to be started from a local panel or a central control room. |

| OUT (Output) | Output Coil | Drives an output coil based on the result of the logical operation, controlling the start/stop of an external device. | Controlling actuators such as motors, solenoid valves, and indicator lights. |

| SET/RST | Set/Reset | Set/Reset instructions are used to maintain an output state even after the input condition is no longer present. | Implementing a “start-stop” latching circuit or latching an alarm signal under specific conditions. |

Understanding the structure and function of these basic instructions is the first step toward diagnosing and resolving instruction failures.

II. The Four Main “Culprits” of PLC Instruction Failure

When a PLC instruction stops working to perform as expected, the trouble can stem from multiple levels. We categorize these possible causes into four primary groups and examine their chance and influence.

2.1 Power Failure

The power supply is the essential guarantee for the steady operation of a PLC system. Power supply failures are one of the most common causes of PLC shutdowns. This type of failure typically shows up as a complete cessation of PLC procedure, with all sign lights switched off.

Cause Analysis

- Unstable External Power: Grid voltage fluctuations, surges, and harmonic disruptions can influence the PLC’s changing power supply.

- Line Connection Issues: Loose power cords, bad contact, or improper grounding can result in power disruption or introduce noise interference.

- Power Supply Module Damage: The PLC’s own power component can fall short because of overload, brief circuits, or maturing elements.

According to commercial automation upkeep information, around 20% -30% of PLC system failings are directly related to power supply problems.

2.2 Communication Failure

Modern PLC systems hardly ever run alone. They exchange data with various other PLCs, HMIs (Human-Machine Interfaces), drives, and sensors through commercial networks like Ethernet, Profibus, and Modbus. An interruption in the interaction link can avoid required data from reaching the PLC or control commands from being sent out.

Cause Analysis

- Physical Connection Problems: Damaged communication cable televisions, loosened adapters, and inadequate guard grounding are common causes.

- Incorrect Network Configuration: IP address conflicts, incorrect subnet mask setups, or errors in baud rate or terminal number setup can interrupt interaction.

- Communication Protocol Mismatch: Inconsistencies in the communication procedure or data layout in between master and slave devices.

- Electromagnetic Interference (EMI): Strong electromagnetic fields can interfere with communication signals, triggering information package loss or errors.

A production line in a manufacturing facility experienced frequent shutdowns. The investigation revealed that the shielding layer of a Profinet communication wire had been eaten via by a rat, triggering recurring communication in between the PLC and a distributed I/O module, which set off a chain of failures.

2.3 Program Errors

Program mistakes are another major category of usual failings, especially throughout the appointing of new projects or the modification of old systems. These errors can be subtle; the PLC itself might continue to run, however the system’s habits does not fulfill assumptions.

Cause Analysis

- Logical Errors: Programming logic is not rigorous and fails to cover all feasible operating conditions, causing abnormal program execution under specific conditions. For example, a necessary interlock condition may be missing.

- Improper Use of Instructions: Incorrect criterion setups for complicated guidelines or calling particular feature blocks at inappropriate times.

- Data Overflow or Type Mismatch: During mathematical procedures or information handling, the result goes beyond the storage space capability of the register, or information kinds are incompatible.

- Program Scan Issues: A program segment is unintentionally skipped (e.g., put after a JUMP direction), or important reasoning is positioned in an interrupt service regimen, causing chaotic execution timing.

Adopting a modular programs method, which includes breaking down intricate programs into independent functional blocks, helps reduce sensible errors and simplifies future maintenance. In addition, making complete use PLC simulation software for offline screening can recognize most rational troubles prior to the program is downloaded to the hardware.

2.4 Equipment and Environmental Aspects

As an industrial-grade computer, a PLC’s equipment is far more reliable than a typical computer. However, in rough industrial settings, hardware failures are still inevitable.

Cause Analysis

- I/O Module Failure: Sintered calls on an input component or a harmed relay/transistor on a result module can stop signals from being read or sent correctly.

- CPU Module Failure: The main handling unit can fail due to getting too hot, fixed electrical power, or aging of inner components, which is often a fatal error.

- Memory Failure: Damage to the memory chips that keep the program or data can cause program loss or data corruption.

- Environmental Factors: Excessive temperature, moisture, dirt, or corrosive gases can increase hardware aging and might even directly cause short circuits or bad call.

The following table sums up the characteristics of the 4 significant failing classifications and their fixing concern:

| Failure Category | Manifestation | Probability | Scope of Impact | Troubleshooting Priority |

|---|---|---|---|---|

| Power Failure | PLC stops completely, POWER light is off | High | Entire PLC system | Highest |

| Communication Failure | Some devices are offline, HMI reports a communication error | Medium | Specific devices related to communication | High |

| Program Error | PLC runs normally, but equipment action is abnormal | High (during commissioning) | Specific function or logic | Medium |

| Hardware/Environment | Specific I/O point is inactive, or PLC reports a hardware error | Low | Single module or entire system | Low (after ruling out others) |

III. Efficient Troubleshooting and Resolution: A Systematic Approach

When a PLC direction stops working, random troubleshooting will only waste time. Complying with a scientific process can yield outcomes much more properly.

3.1 Step 1: Information Gathering and Preliminary Diagnosis

1. Observe PLC Status Indicators:

- ‘PWR ‘( Power) Light: A steady green light indicates the power supply is normal.

- ‘RUN ‘Light: A steady or flashing green light indicates the CPU is in run mode.

- ‘ERR ‘( Error) or ‘FAULT ‘Light: A steady or flashing red light indicates a CPU or program error.

- ‘I/O ‘Lights: Observe whether the standing of the indicator lights for the equivalent input and output points matches the actual signals.

2. Check HMI Alarm Messages: The human-machine user interface usually offers one of the most direct mistake summaries, such as “Motor XX fell short to begin” or “Communication with drive lost”.

3. Inquire with On-Site Operators: Understand the situation before and after the failing happened. Ask what operations they carried out and if they noticed any kind of abnormal devices actions or audios.

3.2 Step 2: Systematic Investigation

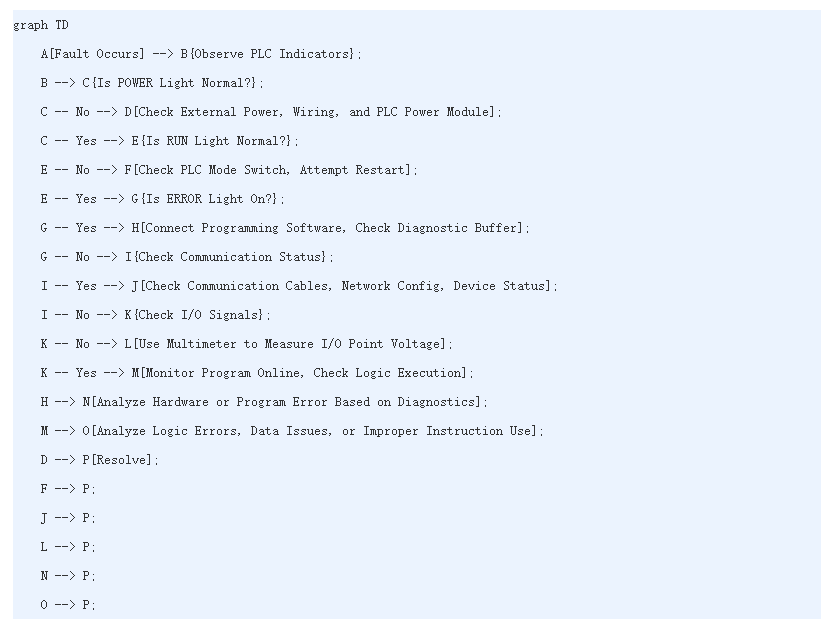

Based on the preliminary diagnosis, adhere to the concept of “external before inner, hardware prior to software application” to conduct a step-by-step investigation.

Troubleshooting Flowchart

3.3 Action 3: In-Depth Analysis and Resolution Using Tools

- Online Monitoring with Programming Software: This is the utmost tool for diagnosing program mistakes. With on the internet monitoring, you can watch the real-time execution standing of the program reasoning and the worth adjustments of variables to quickly identify the issue.

- Diagnostic Buffer: When the PLC spots an interior error, it videotapes detailed mistake information (such as mistake kind, time of event, and related component) in the diagnostic buffer. Reading this details with programming software program is crucial to repairing equipment failures and system-level mistakes.

- Multimeter and Oscilloscope: For hardware-level problems, a multimeter is the fundamental tool for inspecting power supply voltage and the on/off status of I/O factor signals. When fixing high-speed signals or communication disturbance, an oscilloscope can offer an extra exact evaluation.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

Although PLC direction failing is an usual problem, a lot of troubles can be promptly situated and solved by deeply comprehending their working principles and creates, and by understanding a clinical troubleshooting method. More importantly, the emphasis should be on prevention.

Reliable System Design: From the project’s outset, fully take into consideration power supply security and anti-interference abilities, properly lay out the grounding network, and choose top notch PLC items and cables.

Standardized Programming Practices: Follow modular and structured shows concepts, include detailed remarks, and develop an extensive program variation monitoring system.

Regular Maintenance: Periodically evaluate the atmosphere inside the PLC closet (temperature level, humidity, dirt), tighten terminal blocks, and inspect the procedure of cooling followers to make certain the system is always in a great working problem.

By integrating these ideal methods right into day-to-day design, shows, and maintenance work, we can maximize the dependability of PLC automation systems, ensure smooth and efficient manufacturing processes, and ultimately produce better value for the venture.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

How to Transfer PLC Program to New PLC

As Industry 4.0 and Smart Manufacturing initiatives move the world, the core automation assets of many enterprises- their Programmable Logic Controllers (PLCs), are encountering obsolescence and performance bottlenecks.

NPN vs PNP Sensors: Key Differences Explained

Understanding the differences between NPN and PNP sensors is crucial for anyone involved in industrial automation. These sensors are fundamental components in control systems, and knowing how they work can greatly enhance the efficiency and reliability of your operations. This comprehensive guide will demystify NPN and PNP modules and sensors, explain their functionality, and help you decide which type is best suited for your applications.

Understanding VFD: What is a Variable Frequency Drive?

In the realm of industrial automation, Variable Frequency Drives (VFDs) are pivotal components that enhance the efficiency and performance of electric motor systems. This article will explore the fundamentals of VFDs, their functionalities, and the numerous advantages they offer in speed control and energy efficiency.