Navigating the Future: Unpacking the Current State of the Industrial Automation Industry

Table of Contents

What Are the Key Drivers Behind Industrial Automation?

Industrial automation has become an integral part of modern manufacturing and production processes. The adoption of industrial automation is driven by several factors.

Firstly, the need for increased efficiency and productivity is paramount. Automation systems can perform tasks faster and more accurately than humans, leading to significant improvements in output. According to a recent report, companies that implement automation solutions have seen up to a 30% increase in productivity.

Secondly, industrial automation helps reduce operational costs. While the initial investment in automation equipment might be high, the long-term savings are substantial. Automation solutions minimize labor costs, reduce material waste, and improve overall resource utilization.

For example, companies like Rockwell Automation have developed control systems that optimize energy consumption, resulting in significant cost savings. Additionally, the increasing demand for high-quality products is pushing industries to adopt automation.

Automation technology ensures consistency and precision in manufacturing processes, leading to higher quality products that meet stringent market demands.

How is AI Reshaping the Industrial Automation Landscape?

Artificial intelligence (AI) is revolutionizing the industrial automation industry. The integration of AI into automation systems enhances their capabilities, making them smarter and more adaptable.

AI-powered automation solutions can analyze vast amounts of industrial data to identify patterns and insights, enabling predictive maintenance and process optimization. This capability is particularly valuable in complex industrial settings where downtime can be extremely costly.

Moreover, AI facilitates the development of advanced automation technologies that can handle more complex tasks. For instance, AI-driven robotics can perform intricate assembly operations with high precision, surpassing the capabilities of traditional industrial robots.

The use of AI in industrial automation also improves safety by predicting potential hazards and taking preventive measures. Companies are increasingly recognizing the benefits of AI and are investing heavily in its adoption.

What Are the Latest Trends in Robotics and Automation Equipment?

The field of robotics is witnessing rapid advancements, and these innovations are significantly impacting the automation industry. One of the key trends is the development of collaborative robots (cobots) that can work alongside humans in shared workspaces.

Cobots are designed to be safe and easy to use, making them suitable for small and medium-sized enterprises looking to adopt automation. Another important trend is the increasing use of mobile robots for material handling and logistics within factories.

In terms of automation equipment, there is a growing emphasis on modular and flexible systems. Manufacturers are seeking automation solutions that can be easily reconfigured to adapt to changing production needs.

This trend is driven by the need for greater agility and responsiveness in the face of evolving market demands. Additionally, the Industrial Internet of Things (IIoT) is playing a crucial role in enhancing the capabilities of automation equipment.

By connecting machines and devices to a network, IIoT enables real-time data collection and analysis, leading to better decision-making and improved efficiency.

The integration of industrial automation technology with other advanced technologies, like robotics and automation and artificial intelligence, is also a significant trend shaping the industry. These trends collectively point to a future where factory automation systems are more intelligent, interconnected, and adaptable.

What Does the Global Industrial Automation Market Report Reveal?

The global industrial automation market is experiencing robust growth. According to a comprehensive market report, the global industrial automation market size is projected to reach \$326.14 billion by 2027.

This growth is fueled by the increasing adoption of automation technologies across various industrial sectors. The report highlights that the automotive industry currently holds the highest market share, followed by the electronics and semiconductor industry.

Key market players such as Siemens Industrial and other leading companies are driving innovation in the automation industry. The report includes detailed analyses of market trends, growth drivers, and challenges. It also provides market insights into regional markets, with North America and Europe currently leading in terms of market value.

The Asia-Pacific region is expected to witness the fastest growth due to increasing industrialization and the adoption of industrial automation in countries like China and India. Factory automation is particularly prominent, as many manufacturers are looking to modernize their operations with advanced industrial automation systems.

The global industrial automation market report serves as a valuable resource for understanding the current landscape and future prospects of the industry.

Another insight from the report is the expected increase in market growth driven by the emergence of Industry 4.0, which emphasizes the use of interconnected systems, industrial IOT, and smart technologies to enhance productivity and streamline operations.

| Feature | Description |

|---|---|

| Market Size | Projected to reach \$326.14 billion by 2027 |

| Key Drivers | Efficiency, cost reduction, quality improvement, Industry 4.0 adoption |

| Leading Industries | Automotive, electronics, semiconductor |

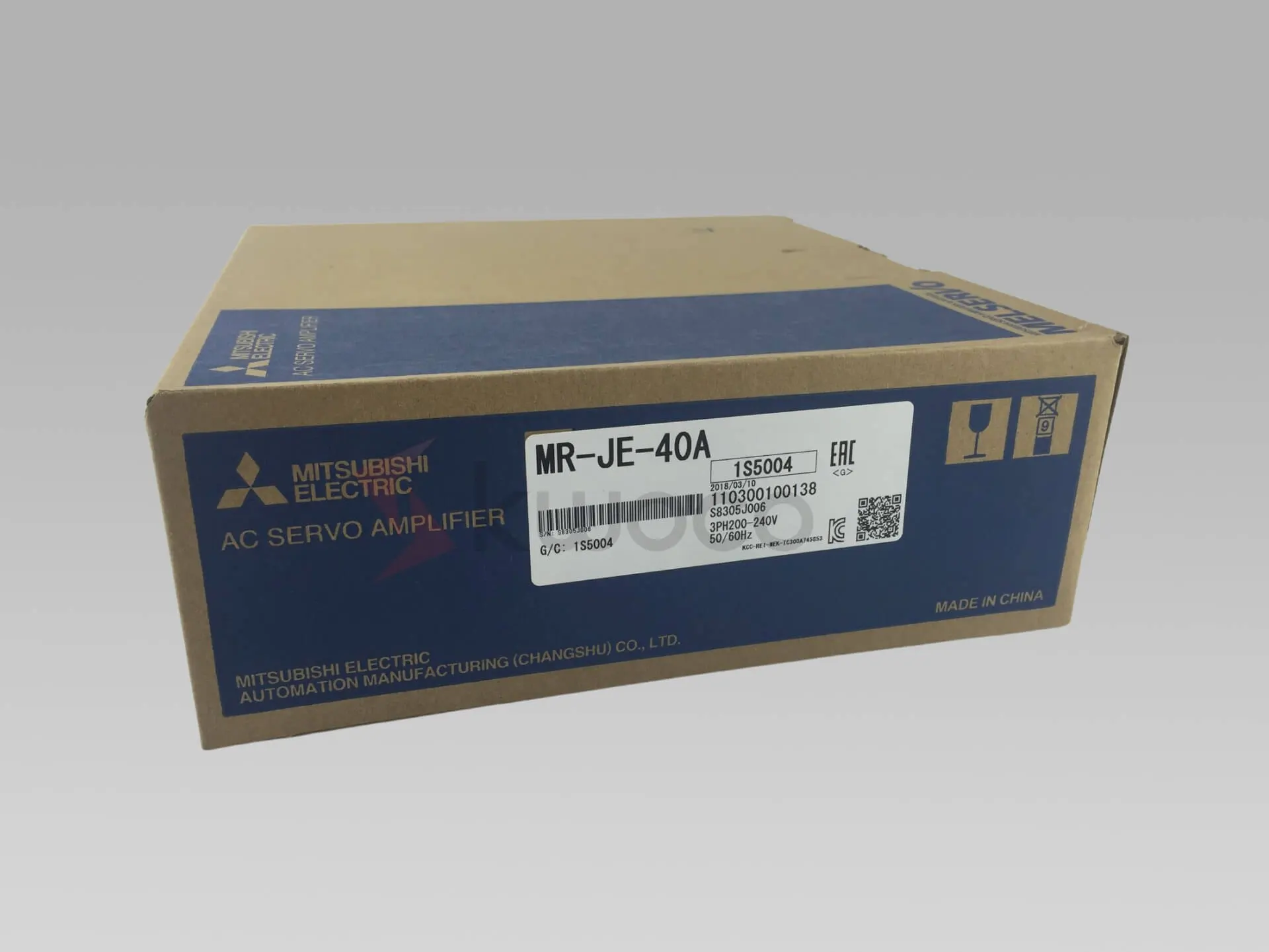

| Key Players | Siemens, Rockwell Automation, ABB, Schneider Electric, Mitsubishi Electric |

| Regional Insights | North America and Europe lead; Asia-Pacific growing rapidly |

| Growth Factors | Technological advancements, increasing industrialization, demand for smart factories |

| Challenges | High initial investment, need for skilled workforce, cybersecurity concerns |

What is the Future of Automation in Industrial Settings?

The future of industrial automation looks promising, with several key trends shaping its trajectory. One of the most significant trends is the continued adoption of Industry 4.0 principles.

This involves the integration of cyber-physical systems, IIoT, and cloud computing to create smart factories that are highly efficient and interconnected.

The future of automation will also see increased use of digital twins, which are virtual replicas of physical systems that can be used to simulate and optimize industrial processes.

Another key aspect of the future of industrial automation is the growing importance of sustainability. Manufacturers are increasingly focused on reducing their environmental footprint, and automation technology can play a crucial role in achieving this goal.

For example, automation systems can optimize energy consumption, reduce waste, and improve resource utilization. Additionally, the future of automation will involve greater collaboration between humans and machines.

While automation will handle many routine tasks, human workers will focus on more complex and creative tasks that require problem-solving and decision-making skills. This collaborative approach will lead to a more balanced and efficient workplace.

As the industry continues to evolve, the adoption of automation technologies will be essential for maintaining competitiveness and driving future growth. The rise of industrial copilot systems is also expected to enhance this collaboration, providing intelligent assistance to human workers.

Frequently Asked Questions

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machineries in an industry to replace a human being.

Implementing automation can lead to increased productivity, reduced operational costs, improved product quality, enhanced safety, and greater flexibility in manufacturing processes.

AI enhances automation systems by enabling predictive maintenance, optimizing processes, handling complex tasks, and improving safety through hazard prediction.

Major market segments include automotive, electronics, semiconductor, aerospace, and healthcare, among others.

IIoT connects machines and devices, enabling real-time data collection and analysis, which leads to better decision-making, improved efficiency, and enhanced automation capabilities.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- Industrial automation significantly boosts productivity and reduces operational costs. If you want to learn more about automation solutions visit our page about Schneider PLC.

- AI is transforming industrial automation by enhancing system capabilities and enabling advanced functionalities.

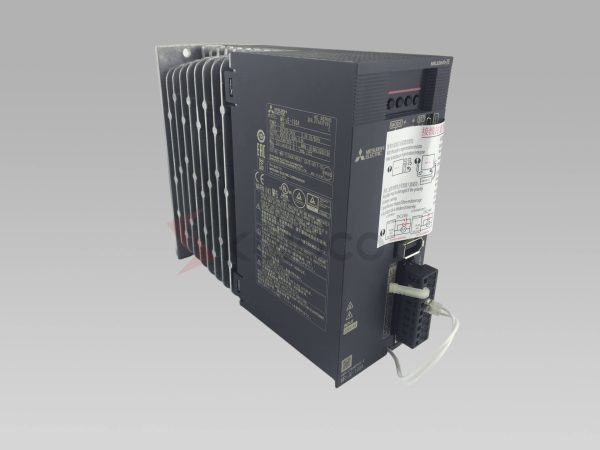

- The latest trends in robotics include the development of collaborative robots and modular automation equipment. If you are interested in learning more about latest trends in automation equipment visit our page about Mitsubishi Servo.

- The global industrial automation market is growing rapidly, driven by technological advancements and increasing adoption across various industries.

- The future of automation involves the integration of Industry 4.0 principles, sustainability initiatives, and greater collaboration between humans and machines.

- Using Omron HMI can improve your systems’ efficiency.

- Investing in Proface HMI offers advanced features and reliable performance.

- Consider integrating Mitsubishi Inverter for enhanced automation capabilities.

This article provides a detailed overview of the current state and future of the industrial automation industry. By understanding these trends and insights, businesses can make informed decisions to leverage automation for growth and success.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Essential Guide to Sensor Calibration for Industrial Accuracy

Sensor calibration is a fundamental part of industrial measurement, essential for ensuring accuracy, reliability, and safe operation in various process plants. Whether dealing with temperature, pressure, or flow, calibrated sensors provide critical data that helps maintain optimal control of industrial operations.

Canada Top 5 Mitsubishi Servo Supplier

As a dedicated engineer at Kwoco, I’ve spent years navigating the industrial automation landscape. My experience with internationally renowned brands like Mitsubishi has equipped me with the knowledge to identify the best suppliers in the market.

Guide to PLC Analog I/O for Automation Engineers

In industrial automation, the concept of analog input and analog output plays a crucial role in the efficient operation of control systems. Whether you are working with a PLC system, sensors, or voltage signals, knowing how these systems interact and how to properly manage signals is key to enhancing your automation processes. This article will dive deep into the essentials of PLC analog inputs and outputs, how to manage voltage and current, and provide insights into practical applications, troubleshooting, and scaling within your automation projects.