Everything You Need to Know About PLC Power Supplies

In this blog, we’ll explore the types of PLC power supplies, their functionality, and their role in modern automation systems.

Table of Contents

What Is a PLC Power Supply?

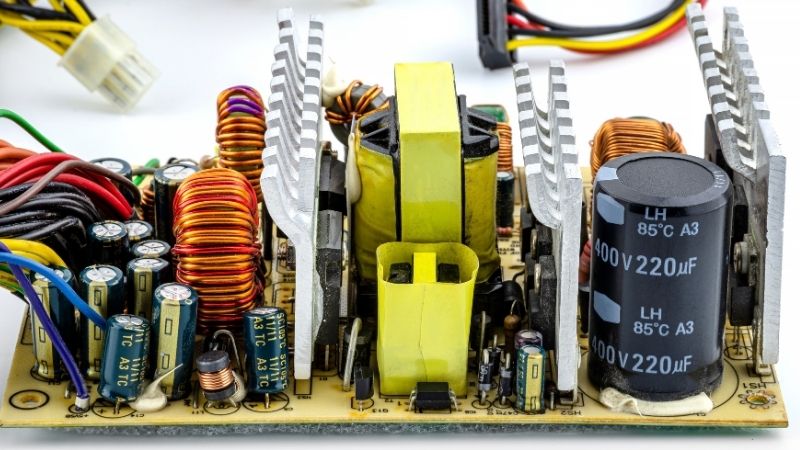

A PLC power supply is a device or module responsible for converting high-voltage alternating current (AC) from the main power source into low-voltage direct current (DC) suitable for a PLC system. It typically steps down the voltage, rectifies it to DC, and stabilizes it for consistent delivery to the PLC.

Most PLC power supplies provide a standard 24V DC output, which powers not only the CPU but also other modules attached to the PLC backplane. In addition, they may incorporate built-in features like overcurrent protection and battery backup to ensure reliability in critical systems.

Types of PLC Power Supplies

PLC power supplies come in various forms, each catering to specific system requirements.

Built-in Power Supplies for Small Systems

Some smaller PLCs, especially compact units with integrated I/O points, come with built-in power supplies. These accept AC input directly and convert it to the necessary DC voltage internally.

- Advantages: Easy installation and reduced need for external components.

- Limitations: Limited current output, making them suitable only for smaller automation systems.

Modular Power Supplies for Larger Systems

Larger PLCs often use modular power supplies attached to the PLC chassis or backplane. These power supplies provide more flexibility and higher power output.

- Advantages: Customizable to match system requirements.

- Limitations: Higher cost and additional installation complexity compared to built-in options.

How PLC Power Supplies Deliver Power

The power supply typically provides power to the CPU and connected modules via the backplane, an internal bus system that distributes energy to all components.

- For Modular PLCs: The power supply module connects to the chassis and delivers power to each module.

- For Built-in PLCs: Power delivery occurs internally, but external wiring may be required for additional field devices.

Selecting the Right PLC Power Supply

Choosing the right power supply involves understanding your system’s requirements. Consider the following factors:

- Input Voltage: Ensure compatibility with the available AC (e.g., 120V or 240V).

- Output Voltage: Most PLCs require 24V DC, but confirm the specifications.

- Current Rating: Match the current output (in amperes) with the system’s power demand. For example, small systems may need 2–10 amps, while larger systems could require up to 50 amps.

The Role of Battery Backups in PLC Power Supplies

Many PLC power supplies incorporate a battery backup system. This feature maintains memory and critical functions during power outages, preventing data loss and operational downtime.

- Battery Maintenance Tip: Regularly check and replace PLC batteries as part of your preventative maintenance schedule.

Powering Field Devices and I/O

It’s important to note that PLC power supplies typically do not power field devices, such as sensors or actuators, directly. These devices require separate DC power supplies.

- Best Practice: Use a dedicated DIN-rail-mounted DC power supply to deliver power to I/O modules and ensure proper circuit completion.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

A reliable PLC power supply is essential for a well-functioning automation system. Whether you’re working with a compact PLC or a modular setup, understanding the types of power supplies, their functionality, and selection criteria can save you from unexpected failures.

If you’re looking for a reliable PLC power supplier, contact Kwoco. We offer brand-new, original products from Omron, Mitsubishi, and Schneider, with worldwide shipping to meet your automation needs.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is PLC Ladder Logic and How Does it Work?

Programmable Logic Controllers (PLCs) are the backbone of industrial automation, and ladder logic is the most popular programming language used to instruct these PLCs. This article delves into the basics of ladder logic, demystifying how it works and why it’s essential for anyone interested in PLC programming to understand. Whether you’re a seasoned engineer or new to automation, this guide will enhance your knowledge and skills.

Capacitive vs. Resistive Touch Screens: Which One Is Right for Industrial Use?

Capacitive vs. Resistive Touch Screens: Which One Is Right for Industrial Use? Ever find yourself torn when choosing a touch

Everything You Need to Know About Contactors and How They Work

This comprehensive guide provides everything you need to know about contactors, including their types, applications, operating principles, and how they compare to relays. Whether you’re an engineer in a machinery and equipment factory, a manufacturer, or part of a factory solution company, understanding contactors is essential for optimizing your industrial automation processes.