Understanding HMI: What It Is and How It Works

- kwoco-plc.com

- October 11, 2024

- 6:39 am

Table of Contents

HMI is the bridge between humans and machines. It combines hardware and software, allowing operators to interact directly with machines or systems through a visual control and monitoring interface. Both touch screens and keyboard interfaces can be part of an HMI.

HMI is known by various technical names, such as:

- Man-Machine Interface (MMI)

- Local Operator Interface (LOI)

- Operator Terminal (OT)

In simple terms, an HMI uses touch screens or displays to provide a more intuitive way for us to operate complex industrial systems.

What Can HMI Do?

HMI can monitor the inputs and outputs of machines or systems in real-time, helping operators understand production trends, time, and key performance indicators (KPIs).

Through HMI, operators can remotely check the status of equipment and adjust settings via touch control when needed.

Differences Between SCADA and HMI

A common misconception is that HMI and SCADA systems are the same, but they are different. SCADA is a complete monitoring system, whereas HMI is just an interface within it. Similarly, HMI and GUI are not the same; the GUI is a part of the HMI system.

- Role and Scope: SCADA is a comprehensive system that manages large-scale monitoring and control tasks across multiple sites or processes. It collects and processes real-time data from various sensors and devices, providing a centralized view of an entire plant or network. In contrast, HMI focuses on providing a localized user interface—typically through touch screens or displays—allowing operators to interact directly with specific machines or subsystems.

- Functionality: SCADA systems can execute advanced control functions, such as data analysis, alarm management, and remote control. In comparison, HMI serves as the interface that operators use for local monitoring and adjusting settings. Think of SCADA as a comprehensive control system, while HMI is the user-friendly, interactive layer.

- Integration with Other Systems: SCADA systems often integrate with other systems like PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units) to manage large-scale distributed processes. HMI typically interfaces directly with these controllers, providing immediate feedback and local control.

- Relationship with GUI: An HMI includes a graphical user interface (GUI), but it is not the same as a GUI. The GUI is the visual aspect that allows interaction, while the HMI encompasses the entire system enabling operator interaction with machines. Thus, while HMI uses GUI principles for its display, it is specifically designed for industrial needs, offering data visualization, real-time metrics, and control features.

Overall, while HMIs and SCADA systems often work together, their scope and functionality make them distinct roles in industrial automation.

How Do You Read PLC Wiring Diagrams? What Are the Rules?

Mastering a few key rules is essential for reading PLC wiring diagrams:

- Read from Left to Right, Top to Bottom: Like reading a book, the reading sequence for wiring diagrams is typically from left to right, top to bottom.

- Use Symbols for Quick Location: The symbols on wiring diagrams represent each component’s position and connections. Familiarizing yourself with these symbols allows you to quickly pinpoint key points in the circuit.

- Pay Attention to Numbering Systems: Many wiring diagrams use page and column numbers, such as “35.2,” indicating that a component is on page 35, column 2.

How to Quickly Master PLC Panel Wiring Diagrams?

- Start with the Main Power, Then Move to Control Circuits: The main power section is usually in the upper left corner of the diagram. Verify the main power connections before checking other control circuits.

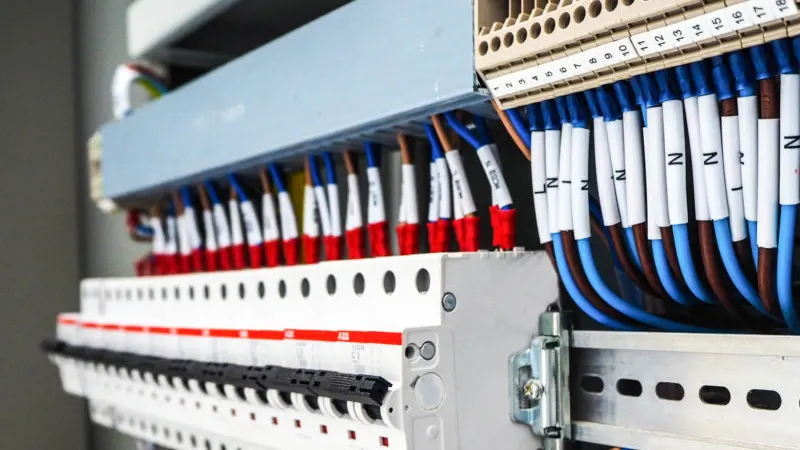

- Identify Inputs and Outputs: Inputs and outputs are often marked with different colors or symbols. Make sure every input device (like sensors) and output device (like motors) is connected correctly.

Why Are Wiring Diagrams So Important for Engineers?

Wiring diagrams are not just installation guides; they also help us troubleshoot quickly. Whenever an issue occurs, we can follow the wiring diagram step by step to locate the problem, avoiding extended downtime.

How to Quickly Locate Fault Points Using Wiring Diagrams?

The key to quickly finding fault points through wiring diagrams is logical troubleshooting and step-by-step inspection.

First, verify whether the power input is normal by checking the connections in the main power section of the diagram. If the system fails to start, it could be a power or fuse issue.

Next, inspect the input and output modules to ensure signals are transmitted correctly. Using the symbols on the wiring diagram, you can narrow down the problem to a specific sensor or actuator, making troubleshooting more efficient.

For example, if a sensor has no signal, check its wiring or replace the module.

Wiring diagrams also help us understand the control circuit’s logic. By checking the logical control section, you can verify whether the PLC’s input signals and output controls align with the design logic.

If a part of the control circuit is malfunctioning, the diagram allows you to identify the issue quickly, avoiding blind repairs. Using tools like a multimeter to measure current and voltage can further validate the circuit’s functionality.

How to Maintain the Electrical Wiring of a PLC Panel?

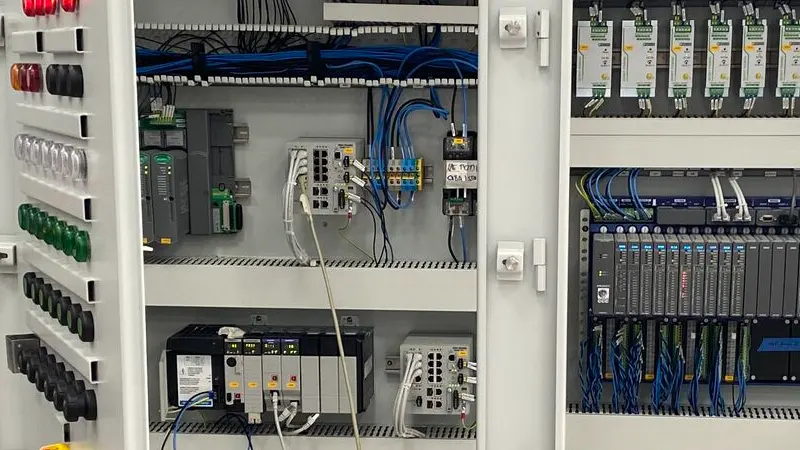

The primary step in maintaining PLC panel wiring is to regularly check the tightness of all connections. Due to vibration and temperature changes in industrial environments, screw terminals may become loose, leading to unstable signal transmission or short circuits.

Ensuring that all connections are secure is crucial. A thorough inspection every few months can significantly improve system reliability.

Additionally, keep the panel dust-free and moisture-resistant. PLC panels often house many delicate electronic components, and dust and moisture can cause terminal corrosion or short circuits.

Regularly clean the inside of the panel with compressed air while the system is running, and avoid placing the panel in highly humid environments. If installation in a damp area is unavoidable, use a waterproof casing or desiccants to extend the panel’s lifespan.

Finally, replace aging wires and components promptly. Long-term use can cause wires to age, leading to insulation damage and increasing the risk of electric leakage or short circuits.

Use the specifications in the wiring diagram to select replacement components that match the original model, ensuring safety and stability.

With these maintenance measures, you can not only extend the life of your PLC system but also reduce downtime caused by wiring issues, keeping your operations running smoothly.

Frequently Asked Questions

What Does “COM” Mean on a Wiring Diagram?

COM usually stands for “common,” serving as a shared connection point for multiple input or output devices. During wiring, it’s crucial to ensure the COM terminal is connected correctly.

How Can I Ensure Wiring Safety?

Use the right cables and terminal blocks, strictly follow the symbols and instructions on the wiring diagram, and most importantly, always perform wiring tasks with the power off.

Why Is It Important to Follow the Wiring Diagram Strictly?

Wiring diagrams are designed based on system requirements and functions. Any deviation could lead to equipment damage or even safety hazards.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

Learning to read PLC panels and wiring diagrams is an essential skill that not only improves work efficiency but also enhances your professional expertise. I hope this article helps you master this skill and makes wiring a less daunting task!

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Why Industrial Ethernet is the Definitive Choice for PLC Automation Networking

In the current wave of smart manufacturing and Market 4.0, the network interaction capacities of Programmable Logic Controllers(PLCs), the core of automation systems, have become critically important. Effective and trusted data exchange is fundamental to achieving inter-device connection, remote tracking, and smart production lines.

Comprehensive Guide to Photoelectric Sensor Types in Industrial Automation

This article delves into the fascinating world of photoelectric sensors, exploring their various types, functionalities, and applications in industrial automation. We aim to provide a comprehensive understanding of how these detectors are transforming manufacturing processes, enhancing efficiency, and ensuring precision. If you’re involved in the machinery and equipment industry, manufacturing, or providing factory solutions, this article offers valuable insights into leveraging photoelectric sensor technology for your operations, and it explains why reading further will equip you with the knowledge to optimize your automation strategies.

PLC Instruction Failures: A Troubleshooting Guide

In the domain name of modern industrial automation, the Programmable Logic Controller (PLC) plays an important role. It serves as the “brain” of the automation system, managing every stage of the manufacturing procedure by implementing a collection of exact guidelines.