What is a Servo and How Does It Work?

Table of Contents

Understanding the Basics

A servo system typically includes a servo motor, a drive (or amplifier), and a controller. The controller sends a command signal to the drive, which powers the motor accordingly. The sensor feeds back the actual position to the controller.This closed-loop system allows for accurate control. It’s what sets servos apart from standard motors.

Types of Servo Motors

There are mainly two types of servo motors: AC and DC. AC servos are generally used in high-speed applications, while DC servos are suited for lower speed, high-torque situations.Each type has its advantages.

Choosing the right one depends on your specific needs.

How Does a Servo Work?

The working principle of a servo revolves around the feedback mechanism. The controller compares the commanded position with the actual position from the sensor.If there’s a difference (called an error signal), the controller adjusts the motor’s operation to correct it.This continuous process ensures the output shaft reaches and maintains the desired position.

Components of a Servo System

- Servo Motor: Converts electrical signals into mechanical motion.

- Drive/Amplifier: Powers the motor based on signals from the controller.

- Controller: Processes inputs and sends commands to the drive.

- Feedback Device: Provides real-time data on position, speed, or torque.

Each component plays a vital role in the system’s performance.

Applications of Servos

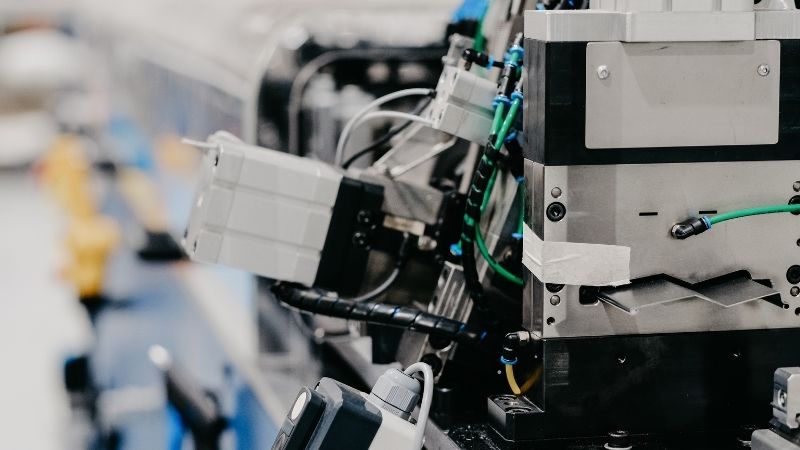

Servos are used in robotics, CNC machinery, conveyors, and more. Anywhere precise motion control is required, servos are the go-to solution.For example, in robotic arms, servos control the movement of joints with high precision.

Benefits of Using Servos

- Precision: Achieve exact movements.

- Speed Control: Adjust speeds dynamically.

- Torque Control: Maintain consistent force.

- Responsiveness: Quick adjustments to changes.

These benefits make servos indispensable in modern automation.

Common Brands and Products

At Kwoco, we stock a wide range of servos from leading brands like Omron, Mitsubishi, Schneider, Panasonic, and Siemens.We only sell new, original products, ensuring quality and reliability.

Choosing the Right Servo

Selecting the appropriate servo involves considering factors like load requirements, speed, torque, and application specifics.I’m always here to help our customers make the best choice for their projects.

Why Buy from Kwoco?

We have over 30 million products in stock, ready to ship immediately. Our one-stop purchasing service is designed for fast product quotation and shipment.Quality is our priority. We understand the concerns about counterfeit goods in the market. Rest assured, with us, you get only genuine products.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servo – in stock, ready now!

Conclusion

Servos play a critical role in automation. Their ability to provide precise control makes them invaluable.

At Kwoco, we’re here to support your needs with quality products and expert guidance. If you’re looking to understand more about servos or need assistance with your next project, feel free to reach out. You can contact me at [email protected]. Visit our website at www.kwoco-plc.com for more information.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Introduction to Programmable Logic Controllers: Your Gateway to Industrial Automation

This article is a comprehensive guide to Programmable Logic Controllers (PLCs), exploring their fundamental role in modern industrial automation. From machinery and equipment factories to manufacturers and solution providers, PLCs are indispensable for streamlining operations and enhancing productivity. This article delves into the intricacies of PLCs, their programming, and their diverse applications.

Limit Switches Explained: Types, Uses, and Working Principles

Limit switches are a critical component in numerous devices and machines, playing a key role in detecting the presence or absence of an object. Whether it’s a refrigerator door or an industrial machine, limit switches are behind-the-scenes heroes, performing functions that ensure smooth operation and safety.

Master Ladder Logic: What You Need to Know

As an engineer at Kwoco, I often get asked, “What exactly is Ladder Logic for PLCs? Is it hard to learn?” Don’t worry. Today, I’ll walk you through this essential and foundational skill.