Siemens PLC Guide: Automation & Programming

Table of Contents

1. What is a PLC and Why Choose Siemens?

A PLC, or Programmable Logic Controller, is essentially a specialized computer used to automate industrial processes. Think of it as the brain of your factory, controlling everything from assembly lines to robotic arms.

Traditional control systems relied on complex wiring of relays and timers, which were difficult to modify and troubleshoot. PLCs offer a more flexible, reliable, and efficient solution.

So, why Siemens? Siemens is a renowned leader in industrial automation, offering a comprehensive lineup of PLCs, software, and services. Their Simatic range of controllers, particularly the S7-1200 and S7-1500, are known for their reliability, performance, and ease of use.

Siemens PLC’s are built for rugged industry environments, ensuring long-term operation and minimizing downtime. Choosing Siemens means choosing a proven technology partner committed to industrial automation excellence. They truly standardize quality.

From the compact S7-200 to the advanced S7-1500, Siemens caters to a wide range of applications, offering scalability and compliance with industry standards. Their simatic controllers are commonly used around the world.

![]()

2. Exploring the Siemens PLC Lineup: From S7-1200 to S7-1500

The Siemens PLC family is diverse, with different models suited for different applications. Understanding the differences between them is fundamental to selecting the right controller for your needs. Let’s focus on two popular choices: the S7-1200 and the S7-1500.

The Simatic S7-1200 is a compact PLC, ideal for smaller automation projects. It’s a great starter PLC for those new to Siemens. It offers a good balance of performance and cost, making it suitable for applications like packaging machines, simple conveyor systems, and building automation.

The S7-1200 is known for its user-friendly programming environment and integrated diagnostics.

On the other hand, the Simatic S7-1500 is a high-performance modular PLC designed for more demanding applications. It boasts faster processing speeds, larger memory capacity, and advanced features like integrated motion control and security functions.

The S7-1500 is a good choice for complex manufacturing processes, robotic applications, and high-speed control systems. Simatic s7-1500 is top of the lineup.

Choosing between the S7-1200 and S7-1500 plc depends on the complexity of your application, the required performance, and your budget.

3. What Programming Languages are Used for Siemens PLC Programming?

PLC Programming involves instructing the PLC on how to control the connected input and output devices. Several programming languages are supported, each with its strengths and weaknesses. The IEC 61131-3 standard defines several programming language options.

Ladder Diagram (LAD) is a graphically oriented language that resembles electrical ladder logic. It’s one of the most commonly used languages for PLC programming, especially for applications involving discrete control (relay logic). Ladder logic is easy to understand for electricians and technicians familiar with relay control circuits. Also known as lad.

Function Block Diagram (FBD) is another graphically oriented language that uses blocks to represent functions and connect them to create a control system. FBD is well-suited for complex control algorithms and continuous processes. Also known as function block diagram.

Structured Text (SCL) is a high-level, text-based language similar to Pascal or C. SCL is ideal for complex mathematical calculations, data manipulation, and advanced control algorithms. Many engineer prefer scl.

Statement List (STL) is a low-level, text-based language that provides direct access to the PLC’s instruction set. STL is often used for optimizing performance and implementing specific control algorithms.

Which programming language should you choose? It depends on your background, the complexity of your application, and your personal preference. For simple applications, ladder may be sufficient. For more complex tasks, SCL or FBD might be more appropriate.

![]()

4. What is TIA Portal and How Does it Simplify Siemens PLC Programming?

TIA Portal (Totally Integrated Automation Portal) is Siemens’ unified software platform for configuring, programming, and commissioning automation systems. It integrates all the necessary tools for PLC programming, HMI design, drive configuration, and network configuration into a single environment. It is the central programming environment.

TIA Portal offers a number of advantages:

- Integrated Engineering: All automation tasks can be performed within a single environment, eliminating the need to switch between different software packages.

- User-Friendly Interface: The intuitive interface makes it easy to learn and use, even for beginners.

- Centralized Data Management: All project data is stored in a central database, ensuring consistency and reducing errors.

- Advanced Diagnostics: Built-in diagnostics tools help you quickly identify and resolve problems.

- Libraries and Reusability: You can create and reuse code libraries, saving time and effort on future projects.

With TIA Portal, you can streamline your PLC programming workflow, reduce engineering time, and improve the overall quality of your automation projects.

5. How do I get Started with Siemens PLC Programming?

Learning Siemens PLC programming is an investment that can significantly enhance your career prospects in the industrial automation field.

Here’s a step-by-step guide to help you get started:

- Choose a PLC: Start with an affordable PLC, such as the Simatic S7-1200, to gain hands-on experience.

- Install TIA Portal: Download and install the TIA Portal software on your computer. Siemens offers trial versions that are free for download.

- Learn the Basics: Familiarize yourself with the fundamental concepts of PLC programming, such as logic gates, timers, counters, and data types.

- Practice with Examples: Work through example projects to gain practical experience. Siemens provides a wealth of example programs and tutorials.

- Take a Training Course: Consider taking a formal training course to learn advanced programming techniques and best practices.

- Join Online Communities: Connect with other PLC programmers online to ask questions, share knowledge, and learn from their experiences.

- Start with the software Soft Comfort.

6. Can I use SCL with Siemens PLC?

Yes! As mentioned earlier, SCL (Structured Control Language) is a powerful, high-level text-based programming language supported by Siemens PLCs, particularly when using TIA Portal. It allows you to write complex logic and algorithms in a structured and readable format.

SCL is especially useful for:

- Performing complex mathematical calculations

- Manipulating data structures

- Implementing advanced control algorithms

- Creating reusable function block

Using SCL can improve the readability and maintainability of your code, especially for complex projects. While ladder logic is great for simple relay based operations, SCL helps to organize more complex processes, similar to how you might use a programming language to control a computer.

7. What are the Key Components of a Siemens PLC System?

A typical Siemens PLC system comprises several key components working together to control an industrial automation process.

- Central Processing Unit (CPU): The CPU is the brain of the PLC, executing the programme and controlling the input and output modules. Different CPUs offer varying processing power, memory capacity, and communication ports.

- Input Modules: Input modules receive signals from field devices, such as sensors, switches, and pushbuttons, and convert them into digital signals that the CPU can understand. They help the cpu interface with the outside world.

- Output Modules: Output modules receive signals from the CPU and convert them into electrical signals that can control field devices, such as actuators, valves, and motors.

- Power Supply: The power supply provides the necessary ac or voltage to power the PLC system.

- Communication Modules: Communication modules enable the PLC to communicate with other devices, such as HMIs, other PLCs, and computers, using various protocols, such as Profinet or Ethernet.

- Interface Modules: Interface modules allow you to expand the PLC system by adding additional input/output or communication modules.

Understanding these components is crucial for designing, installing, and maintaining Siemens PLC systems.

![]()

8. How can Siemens PLC enhance my Industrial Automation processes?

Siemens PLCs offer a wide range of benefits for industrial automation:

- Increased Productivity: Siemens PLC’s can automate repetitive tasks, reducing cycle times and increasing overall productivity.

- Improved Quality: Precise control and monitoring capabilities ensure consistent product quality and reduce defects.

- Reduced Downtime: Advanced diagnostics and remote monitoring capabilities enable quick identification and resolution of problems, minimizing downtime.

- Increased Flexibility: PLCs can be easily reprogrammed to accommodate changes in production requirements, providing greater flexibility.

- Reduced Costs: Automation can reduce labor costs, energy consumption, and waste, leading to significant cost savings.

By implementing Siemens PLC systems, manufacturers can optimize their operations, improve efficiency, and gain a competitive edge. Consider industrial automation for your business.

9. What are the benefits of WinCC in my Siemens PLC project?

WinCC is Siemens’ Human Machine Interface (HMI) software that allows operators to monitor and control industrial automation processes. It provides a graphical interface for visualizing data, controlling equipment, and receiving alarms.

WinCC offers several key benefits:

- Improved Operator Efficiency: Intuitive graphical displays and controls make it easier for operators to monitor and control the process.

- Enhanced Data Visualization: Real-time data visualization helps operators quickly identify trends and anomalies.

- Centralized Monitoring: All critical process data can be monitored from a central location, providing a comprehensive overview of the operation.

- Improved Alarm Management: Advanced alarm management features help operators quickly respond to critical events.

- Remote Access: Remote access capabilities allow operators to monitor and control the process from anywhere.

Integrating WinCC with your Siemens PLC system can significantly improve operator efficiency, enhance data visualization, and provide a more comprehensive view of your automation process.

10. Where can I find support and training for Siemens PLC systems?

Siemens offers a wealth of resources for PLC support and training:

- Siemens Website: The Siemens website provides access to product documentation, FAQs, application examples, and training courses.

- Siemens Industry Online Support: This online portal offers a comprehensive knowledge base, forums, and support requests.

- Siemens Automation Cooperates with Education (SCE): The SCE program provides educational institutions with Siemens automation equipment and training materials.

- Authorized Training Partners: Siemens has a network of authorized training partners that offer instructor-led training courses.

- Online Communities: Numerous online communities and forums provide a platform for PLC programmers to connect, share knowledge, and ask questions.

Siemens us is a great place to start. Take advantage of these resources to enhance your Siemens PLC skills and stay up-to-date with the latest technologies.

Frequently Asked Questions

A PLC is designed for industrial environments and real-time control, offering ruggedness and specialized I/O modules. A microcontroller is a general-purpose embedded computer often used in consumer electronics and smaller-scale applications.

The Siemens S7-1200 is a great starting point due to its ease of use, integrated diagnostics, and comprehensive programming tools within the TIA Portal.

Siemens offers a wide range of PLCs and automation solutions, a tightly integrated software platform (TIA Portal), and a strong global presence. Siemens’ commitment to innovation and reliability makes them a popular choice in many industries. Although, Rockwell and Omron are also great plc manufacturers.

Use the diagnostics tools in TIA Portal to monitor the PLC’s status, check for errors, and trace the execution of the programme. Review the hardware configuration, network settings, and code, looking for discrepancies.

Profinet is an industrial automation Ethernet protocol used for communication between PLCs, HMIs, and other devices. Siemens PLCs commonly use Profinet for high-speed, reliable data exchange.

Power your projects with brand-new, original Omron, Siemens, Schneider PLC – in stock, ready now!

Conclusion

- Siemens PLCs are powerful tools for industrial automation, offering increased productivity, improved quality, and reduced downtime.

- The Simatic S7-1200 is ideal for smaller applications, while the S7-1500 is suitable for more demanding tasks.

- TIA Portal simplifies PLC programming with its integrated engineering environment and user-friendly interface.

- SCL is a powerful programming language for implementing complex control algorithms.

- WinCC provides a graphical interface for monitoring and controlling automation processes.

- Siemens offers a wealth of resources for PLC support and training.

- Consider exploring Proface HMI for your human-machine interface needs to enhance your industrial automation processes.

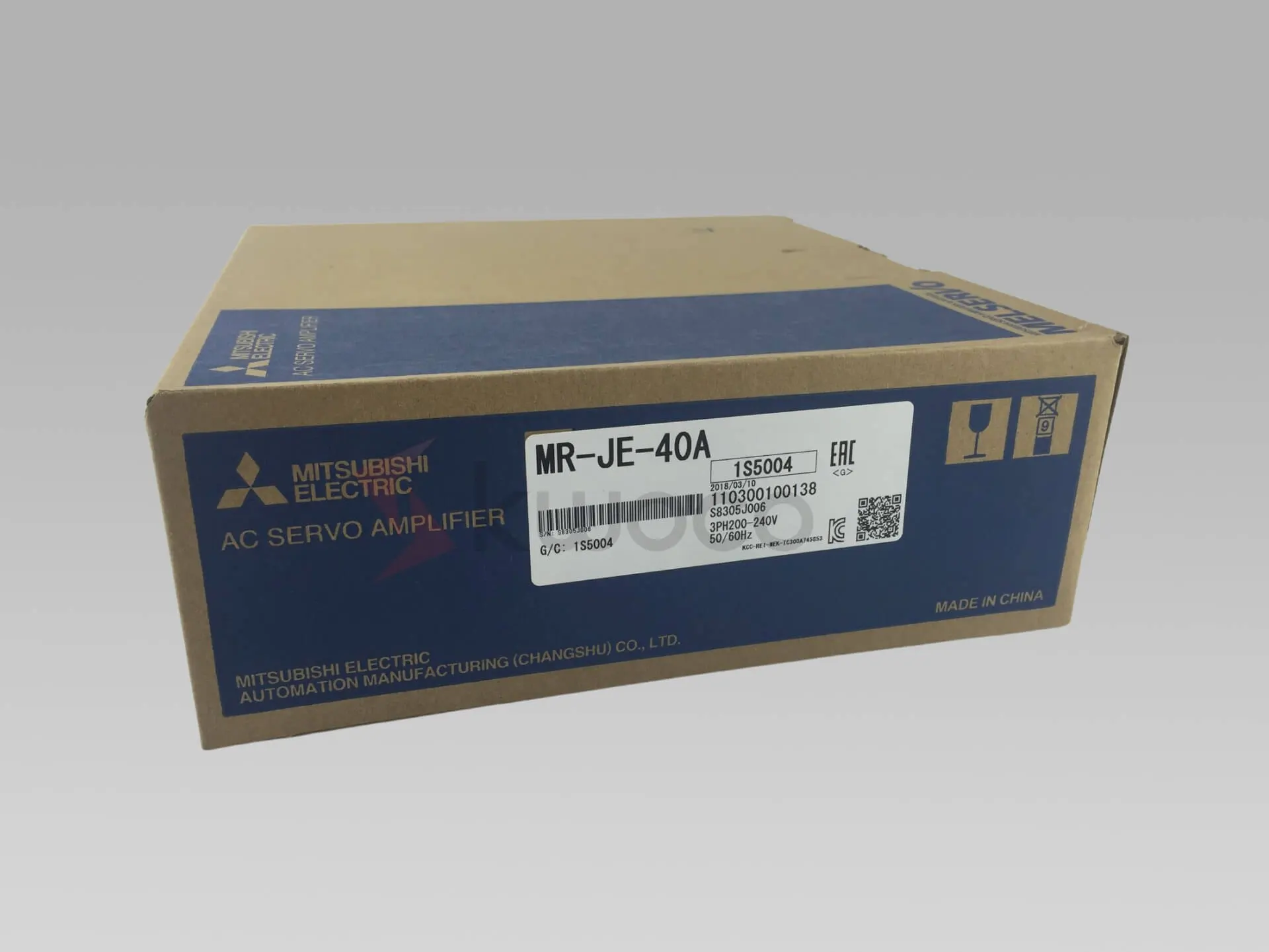

- Take the time to explore the world of Mitsubishi Servo, it might be a better fit for your needs.

- Explore the world of Omron HMI to find a HMI to fit your needs.

Ready to unlock the potential of Siemens PLC for your manufacturing plant? Contact us today to discuss your specific needs and learn how our expertise can help you optimize your operations and achieve your industrial automation goals. We’re here to help you navigate the world of Siemens PLCs and find the perfect solution for your factory.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is the Function of Omron PLC?

What is the Function of Omron PLC? Are you tired of dealing with unreliable control systems that cause delays and

What Is a PLC Panel? A Guide to Electrical Automation

The PLC control panel is the cornerstone of modern industrial automation, orchestrating complex processes with precision and efficiency. Understanding what a PLC panel is and how it functions is essential for anyone involved in industrial operations. This comprehensive guide will illuminate the world of programmable logic controllers and their pivotal role in automating industrial processes.

Why Choose Allen-Bradley PLCs for Your Project?

Why Choose Allen-Bradley PLCs for Your Project? Struggling with selecting the right PLC for your engineering projects? You’re not alone.