Mastering PLC Panels: A Guide to Reading Wiring Diagrams

- kwoco-plc.com

- October 28, 2024

- 8:26 pm

Table of Contents

What is a PLC and How Does It Work?

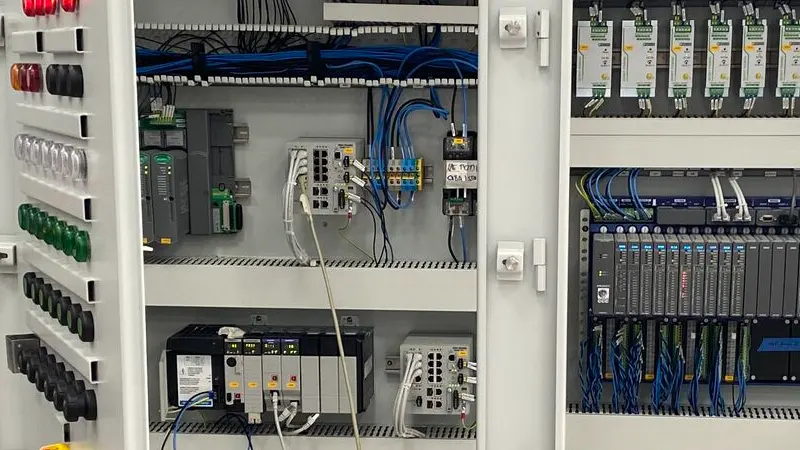

Programmable Logic Controllers (PLCs) are specialized computers used in industrial automation to control machinery and processes. They monitor inputs, make decisions based on their program, and control outputs to automate tasks. PLCs are designed for industrial applications, capable of withstanding harsh conditions like extreme temperatures, electrical noise, and mechanical vibrations.

At the heart of a PLC is a dedicated processor or CPU that executes a PLC program, typically written in ladder logic, a graphical programming language resembling electrical relay logic diagrams. This makes it easier for engineers familiar with electrical control systems to program and maintain PLCs. PLCs are designed to run continuously, often for years without failure.

PLC components include:

- Power Supply: Provides the necessary power to the system.

- CPU (Central Processing Unit): The brain of the PLC, executing control instructions.

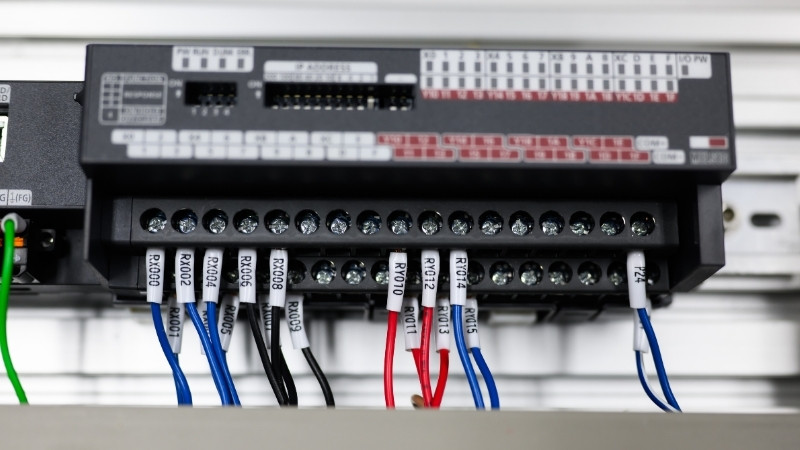

- Input and Output Modules: Interfaces for sensors (inputs) and actuators (outputs).

PLCs are integral to industrial control systems, handling complex process control tasks with reliability and precision.

Introducing the Raspberry Pi: A Single-Board Computer Revolution

- Processor: Quad-core 1.5GHz CPU.

- Memory: Up to 8GB RAM.

- Connectivity: Dual-band Wi-Fi, Bluetooth 5.0, and Ethernet port.

- Interfaces: USB ports, HDMI outputs, and camera interfaces.

Can the Raspberry Pi Replace a PLC in Industrial Control Systems?

This question has sparked considerable debate in the automation community. To evaluate whether the Raspberry Pi can replace a PLC in industrial control systems, we need to consider several factors.

PLCs are designed specifically for industrial applications, offering robustness, reliability, and real-time performance. They handle extreme environmental conditions and are built for critical applications where failure is not an option.

The Raspberry Pi, while powerful, is a consumer-grade device not originally intended for industrial use. It lacks the rugged hardware and software designed to withstand harsh industrial environments. The Raspberry Pi’s reliance on an operating system can introduce latency and unpredictability, which are unacceptable in many industrial automation scenarios.

Moreover, PLCs process inputs and outputs 60 times per second or faster, ensuring timely responses to changing conditions. The Raspberry Pi may struggle to meet these real-time requirements due to its general-purpose nature.

PLC vs Raspberry Pi: A Comparative Analysis

When comparing PLC vs Raspberry Pi, several key differences emerge:

| Feature | PLC | Raspberry Pi |

|---|---|---|

| Design Purpose | Industrial automation | Education and hobbyist projects |

| Reliability | High, designed for harsh conditions | Moderate, not industrial-grade |

| Programming Language | Ladder logic, easy for engineers | Python, requires coding skills |

| Real-Time Performance | Real-time operation | Not guaranteed |

| Cost | Higher upfront cost | Lower upfront cost |

| Inputs/Outputs | Built-in industrial I/O modules | Requires additional modules |

| Maintenance | Supported by PLC manufacturers | Community support |

Research indicates that while commercially available industrial-grade PLCs have a higher upfront cost than systems built from consumer electronics, such as the Raspberry Pi, the additional investments required to make consumer electronics suitable for industrial applications—like adding significant mission-specific hardware and software—can reduce or eliminate the initial cost advantage.

This means that while the Raspberry Pi might be cheaper initially, the expenses to make it industrial-ready may close the cost gap.

Using a Raspberry Pi for Programmable Logic Control

Using the Raspberry Pi as a Programmable Logic Controller involves programming it to perform control tasks typically handled by a PLC. Projects like the OpenPLC Project provide open-source platforms for this purpose.

To use the Raspberry Pi as a PLC, you need to:

- Install the Operating System: Use a Linux distribution like Raspbian.

- Set Up the Programming Environment: Install necessary libraries and tools, such as Python or ladder logic programming environments.

- Add Input and Output Interfaces: Use modules like relay boards to connect sensors and actuators.

- Develop the Control Program: Write code to handle inputs, process data, and control outputs.

- Ensure Industrial Compatibility: Implement measures to protect against electrical noise, temperature extremes, and mechanical stress.

However, this approach requires significant mission-specific hardware and software to ensure reliability. Users must properly integrate hardware and software, which can be complex and time-consuming.

How to Program a Raspberry Pi for Industrial Control Applications

Programming a Raspberry Pi for industrial control applications involves several steps:

- Hardware Setup: Connect the Raspberry Pi to sensors (inputs) and actuators (outputs) using appropriate modules.

- Software Installation: Install a suitable programming environment, such as Python with GPIO libraries or specialized control software.

- Developing the Program: Write the control logic, ensuring it meets the real-time requirements of your application.

- Testing: Rigorously test the system under various conditions to ensure reliability.

- Deployment: Install the Raspberry Pi in an environment that protects it from industrial hazards.

Analog signals may require additional hardware like ADCs (Analog-to-Digital Converters) for the Raspberry Pi to process them. Additionally, consider using industrial communication protocols like Ethernet for network connectivity.

Integrating Arduino with Raspberry Pi and PLCs

Arduino boards are microcontroller platforms popular among hobbyists for their simplicity and ease of use. Integrating Arduino with Raspberry Pi and PLCs can create a powerful hybrid system.

- Arduino and Raspberry Pi: The Arduino handles real-time control tasks, while the Raspberry Pi manages data processing and network communication.

- Interfacing with PLCs: Use communication protocols to connect the hybrid system to existing PLCs, enhancing functionality without replacing proven systems.

This combination leverages the strengths of each platform but may not be suitable for critical applications without significant testing and validation.

Are Raspberry Pis Suitable for Critical Applications?

In critical applications where safety and reliability are paramount, PLCs are often the preferred choice. Raspberry Pis are not designed for such environments and may lack the necessary certifications and robustness.

Do-it-yourself options can be cost-effective but require considerable attention to properly integrate hardware and software. The risk of failure in critical applications may outweigh the cost benefits of using a Raspberry Pi over a traditional PLC.

PLC and Raspberry Pi: Bridging the Gap in Industrial Automation

Combining a PLC and Raspberry Pi can offer the best of both worlds:

- PLC: Handles real-time control with proven reliability.

- Raspberry Pi: Manages data analysis, user interfaces, and network connectivity.

For example, a PLC could control a water heater, maintaining a specified outlet temperature using traditional ladder logic. The Raspberry Pi could collect data from the PLC, visualize performance, and send alerts if anomalies are detected.

This integration allows for advanced features without compromising on reliability.

Future of Industrial Control: Will Raspberry Pi Take Over PLCs?

The range of automation platform options is the greatest it has ever been, offering new possibilities for industrial control. However, the Raspberry Pi is unlikely to completely replace PLCs in the near future.

Users must research thoroughly and choose carefully to obtain the best result. Factors to consider include:

- Application Requirements: Reliability, real-time performance, environmental conditions.

- Cost: Total cost of ownership, including maintenance and downtime risks.

- Support and Maintenance: Availability of spare parts, technical support, and documentation.

PLCs will continue to be the backbone of industrial automation, but the Raspberry Pi and similar devices may play supportive roles.

Frequently Asked Questions

Can a Raspberry Pi be used as a PLC?

Yes, a Raspberry Pi can be programmed to perform some functions of a PLC using appropriate software and hardware interfaces. Projects like the OpenPLC Project enable this functionality. However, it may not offer the same level of reliability required for industrial applications.

What programming languages are used for Raspberry Pi and PLCs?

The Raspberry Pi commonly uses programming languages like Python, while PLCs use ladder logic programming or other specialized languages designed for industrial control.

Is it cost-effective to replace a PLC with a Raspberry Pi?

While a Raspberry Pi is less expensive upfront, replacing a PLC may require significant mission-specific hardware and software, offsetting cost savings. Reliability and maintenance considerations may make PLCs more cost-effective in the long run.

Can Arduino be integrated with Raspberry Pi for industrial control?

Yes, integrating Arduino with Raspberry Pi can enhance control capabilities. However, for industrial control applications, this setup may not meet necessary standards for reliability and safety.

What are the limitations of using a Raspberry Pi in industrial environments?

The Raspberry Pi is not designed for industrial environments. It may lack features like industrial-grade components, built-in electrical isolation, and resistance to extreme temperatures or electrical noise.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

While the Raspberry Pi offers exciting possibilities in automation, it is not a direct replacement for a PLC in industrial settings. For hobbyists and educational purposes, it provides a valuable platform for learning and experimentation.

Deploying a Raspberry Pi controller in a production system requires careful consideration of reliability and safety. Commercially available industrial-grade products cost more than systems built from consumer electronics, but they provide the robustness needed for industrial environments.

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Master Ladder Logic: What You Need to Know

As an engineer at Kwoco, I often get asked, “What exactly is Ladder Logic for PLCs? Is it hard to learn?” Don’t worry. Today, I’ll walk you through this essential and foundational skill.

Step-by-Step Guide to Programming Omron PLCs for Beginners

Programmable Logic Controllers (PLCs) are essential components in industrial automation, and Omron PLCs are among the most widely used in the industry. If you’re new to PLC programming, this step-by-step guide will walk you through the basics of programming Omron PLCs, helping you get started with confidence.

Why Industrial Ethernet is the Definitive Choice for PLC Automation Networking

In the current wave of smart manufacturing and Market 4.0, the network interaction capacities of Programmable Logic Controllers(PLCs), the core of automation systems, have become critically important. Effective and trusted data exchange is fundamental to achieving inter-device connection, remote tracking, and smart production lines.