How PLC and SCADA Systems Communicate Efficiently

- kwoco-plc.com

- October 12, 2024

- 6:59 am

Have you ever encountered delayed data transmission or control failure on a production line? If so, understanding how PLC and SCADA communicate is essential.

Table of Contents

How is Communication Between PLC and SCADA Established?

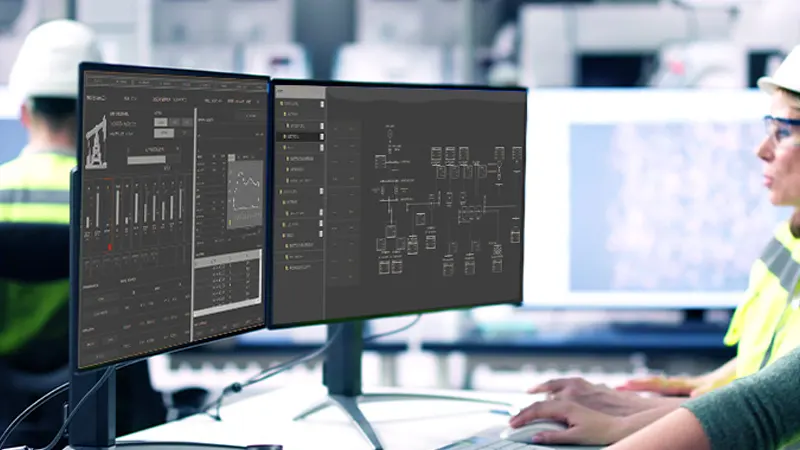

A PLC (Programmable Logic Controller) controls equipment, while SCADA (Supervisory Control and Data Acquisition) monitors and displays data. The PLC, a hardware device, controls equipment by connecting to input and output points. SCADA, operating on a computer or server, visualizes the factory’s real-time status.

When the PLC runs a program, it transmits data to the SCADA system using communication protocols. SCADA monitors this data and displays it to operators through a virtual interface.

It’s important to note that SCADA does not directly control input and output but sends commands to the PLC, ensuring the factory operates efficiently and safely.

How to Ensure Efficient Communication Between PLC and SCADA?

Communication between PLC and SCADA typically uses protocols like Modbus, Profibus, and Ethernet/IP.

Modbus: An open protocol that is simple and easy to implement. It’s widely used for data exchange between devices, supporting both serial communication (like RS-232 and RS-485) and Ethernet communication (like Modbus TCP). It is ideal for basic data transmission needs.

Profibus: A fieldbus protocol developed in Germany, known for high-speed transmission and interference resistance. It’s suitable for complex applications in mechanical manufacturing and process control, with a flexible topology for different levels of device communication.

Ethernet/IP: An industrial Ethernet-based protocol that combines the speed and flexibility of Ethernet with the real-time capability of the CIP protocol. It is commonly used in applications requiring real-time control, such as robotics and factory automation.

Different brands of equipment have specific protocol requirements. For example, Siemens PLCs typically use MPI or Profinet, while Mitsubishi PLCs may use CC-Link.

- Siemens MPI and Profinet:

- MPI is a multi-point interface protocol commonly used in Siemens S7 series PLCs for communication over short distances between a small number of devices, particularly in S7-300 and S7-400 controllers.

- Profinet, an open industrial Ethernet protocol, supports high-speed communication and multiple device connections, making it ideal for large factories and automated systems.

- Mitsubishi CC-Link:

- CC-Link, developed by Mitsubishi, is a fieldbus protocol designed for factory automation and device control systems. It supports high-speed data transfer and large data volumes, making it essential in Mitsubishi’s PLC systems.

In SCADA, tags are defined to connect with PLC data addresses. Each input/output signal has a unique address, and SCADA tags act as “mirrors” of these addresses.

When data in the PLC updates, the corresponding SCADA tag synchronizes in real time, ensuring operators have up-to-date information. For example, alarm tags can read status information from PLCs and display or trigger alarms within the SCADA system.

Frequently Asked Questions

How to Correctly Map PLC and SCADA Tags?

Each I/O address in the PLC must have a corresponding tag in SCADA. Correctly configuring these tags ensures real-time data reading and synchronization. Consistency in tag addresses and data types is crucial to avoid data reading errors.

How to Ensure Real-Time Communication Between SCADA and PLC?

Real-time communication relies on protocols like Modbus and Profinet, along with polling mechanisms. Setting appropriate polling frequencies and avoiding unnecessary tag scans helps reduce network latency and improve data synchronization.

What Happens If PLC and SCADA Lose Connection?

In the event of disconnection, SCADA systems usually log the last available data and trigger alerts to notify operators. Some systems support automatic reconnection and allow pending tasks to resume once the connection is restored.

Are Different PLC Brands Compatible with SCADA Systems?

Most SCADA systems support multiple communication protocols such as Modbus and Ethernet/IP, making them compatible with various PLC brands. For seamless integration, the appropriate protocol must be selected based on the PLC model, and tags should be correctly configured in the SCADA system.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

The collaboration between PLC and SCADA enables intelligent factory management. Through a fast and stable communication system, every aspect of the factory operates smoothly, enhancing productivity and preventing downtime caused by equipment failures. If you want to learn more about automation control, feel free to reach out to us.

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Exploring the Power of Sensors: Types, Uses, and Applications

Sensors are all around us, working quietly behind the scenes to make our lives more convenient, efficient, and safe. From turning on lights when we enter a room to ensuring safety in our vehicles, sensors are integral to modern technology.

10 Reasons to Choose Mitsubishi Servo Systems

10 Reasons to Choose Mitsubishi Servo Systems Kwoco As a company specializing in automation products, we have extensive experience with

Why Your PLC Needs a Separate Power Supply

Why Your PLC Needs a Separate Power Supply Have you ever wondered why PLC systems often require a separate power