What is PLC Ladder Logic and How Does it Work?

Table of Contents

What Is Ladder Logic in PLC Programming?

Ladder logic is a graphical programming language used to develop software for PLCs. But what exactly makes ladder logic so indispensable in the world of automation?

The Origin and Purpose of Ladder Logic

Originally modeled after electrical relay circuits, ladder logic was designed to simplify the transition from relay logic hardware to programmable systems. It mimics the layout of electrical circuits, making it intuitive for engineers familiar with traditional circuit diagrams.

Structure of Ladder Logic Diagrams

A ladder logic diagram resembles a ladder, with two vertical rails and horizontal rungs. The left rail represents the power supply, while the right rail is the ground. Each rung represents a ladder logic instruction, defining a specific operation.

Why Ladder Logic Is a Preferred Programming Language

- Intuitive Design: Its graphical nature makes it easier to visualize and understand the control flow.

- Ease of Learning: Engineers can learn ladder logic quickly due to its resemblance to electrical schematics.

- Wide Acceptance: Being one of the oldest PLC programming languages, it’s widely supported across different PLC brands.

How Does Ladder Logic Work in a PLC?

Understanding how ladder logic works is crucial for effective PLC programming. Let’s explore the mechanics behind it.

The Flow of Logic from Left to Right

In ladder logic, the control flow moves from the left rail to the right, scanning each ladder logic rung sequentially. This mimics the flow of electricity in a physical circuit.

Input and Output Processing

- Inputs: These are conditions or signals read from sensors or user inputs. They are represented by symbols like contacts.

- Outputs: Actions executed by the PLC, such as activating motors or lights, represented by coils or other output symbols.

Logic Operations and Instructions

Ladder logic uses standard logic operations like AND, OR, and NOT to control the flow of the program. By combining these operations, complex control schemes can be implemented.

Key Symbols and Instructions in Ladder Logic

To effectively read ladder logic diagrams, familiarity with its symbols is essential.

Common Ladder Logic Symbols

| Symbol | Meaning |

|---|---|

| –[ ]– | Normally Open Contact (Input) |

| –[\]– | Normally Closed Contact (Input) |

| –( )– | Coil (Output) |

| –(M) | Memory Coil |

| –(T) | Timer |

| –(C) | Counter |

Understanding Ladder Logic Instructions

- Contacts: Represent input conditions.

- Coils: Represent output actions.

- Timers and Counters: Used for operations that require time-based control.

The Advantages of Using Ladder Logic for PLCs

Why do many engineers and technicians prefer ladder logic over other PLC programming languages?

Ease of Troubleshooting and Maintenance

The visual nature of ladder logic diagrams allows for easier troubleshooting. Technicians can quickly identify faulty rungs or logic errors.

Compatibility Across Different PLC Brands

Most PLC manufacturers support ladder logic, making it a universal language in industrial automation.

Flexibility and Scalability

From simple to complex systems, ladder logic programs can be scaled accordingly, providing flexibility for various applications.

How to Learn and Implement Ladder Logic Programming

Embarking on a journey to learn ladder logic? Here are some steps and tips to get you started.

Start with the Basics of Ladder Logic

- Understand the Symbols: Familiarize yourself with basic symbols and their functions.

- Study Simple Programs: Begin by analyzing simple ladder logic diagrams.

Practice with Real PLCs or Simulators

- Use Simulation Software: Tools like PLCSim allow you to write and test ladder logic programs without physical hardware.

- Hands-On Experience: Working with actual PLCs like Omron PLC or Mitsubishi PLC enhances understanding.

Resources and Training

- Online Courses: Many platforms offer courses on PLC programming ladder logic.

- Workshops and Seminars: Attend industry events to gain insights and practical knowledge.

Frequently Asked Questions

Ladder logic is used as a programming language to create programs that instruct a PLC on how to perform control tasks.

While it may seem complex at first, ladder logic is relatively easy to learn, especially for those familiar with electrical control systems.

Most PLCs, including those from Schneider, support ladder logic, making it a widely used language in automation.

The basic components include contacts (inputs), coils (outputs), timers, counters, and rungs that represent the control logic.

Unlike text-based programming languages, ladder logic is graphical, making it more intuitive for designing and visualizing control processes.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

Ladder logic remains a fundamental skill in the field of industrial automation. Its intuitive design and widespread acceptance make it an ideal choice for programming PLCs. By understanding the basics of ladder logic, engineers and technicians can design, troubleshoot, and maintain complex control systems efficiently.

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Guide to PLC Analog I/O for Automation Engineers

In industrial automation, the concept of analog input and analog output plays a crucial role in the efficient operation of control systems. Whether you are working with a PLC system, sensors, or voltage signals, knowing how these systems interact and how to properly manage signals is key to enhancing your automation processes. This article will dive deep into the essentials of PLC analog inputs and outputs, how to manage voltage and current, and provide insights into practical applications, troubleshooting, and scaling within your automation projects.

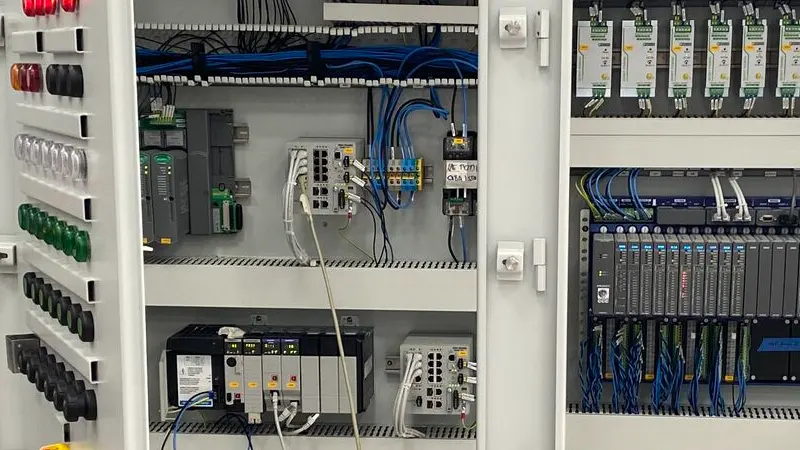

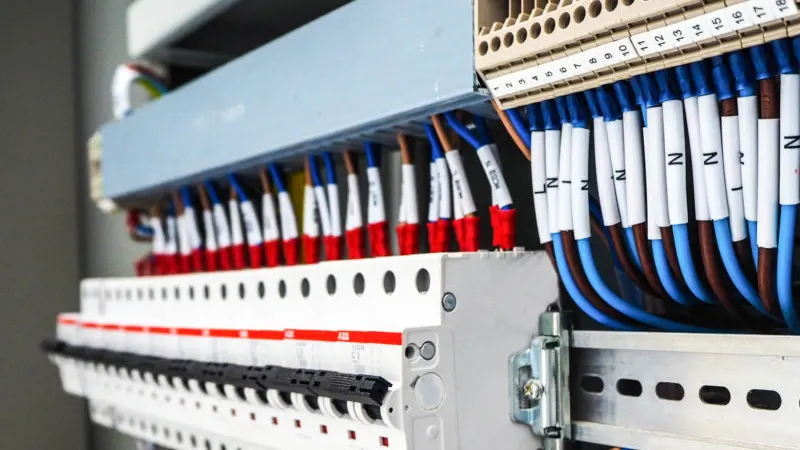

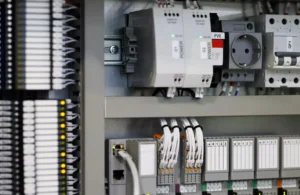

Mastering PLC Panels: A Guide to Reading Wiring Diagrams

As an industrial automation engineer, I deal with PLCs (Programmable Logic Controllers) every day. If you’re like me—deeply interested in automation but often overwhelmed by those complex wiring diagrams—this article is definitely for you.

Do Touch Screens Work? Understanding the Technology Behind Touch Input

Touch screens have become an integral part of our daily lives, from smartphones to industrial control panels. But have you ever stopped to wonder how these touchscreens actually work? This article dives deep into the technology behind touch screens, exploring different types, their applications in industrial automation, and what makes them tick. Understanding the intricacies of touchscreen technology will equip you to make informed decisions about implementing them in your machinery and equipment factory, or factory solution company. We’ll explore the common challenges and how you, as a manufacturer, can leverage this tech to improve your processes.