PLC Interconnectivity: Bridging Data Silos for Smart Manufacturing

Table of Contents

This post looks into the essential value of inter-PLC interaction, discovers mainstream interaction approaches, evaluates core protocols and their efficiency differences, and, via information contrasts and functional study, guides readers on picking and configuring ideal interaction options.

Introduction: The Inevitability of PLC Interconnectivity in the Smart Manufacturing Era

In the current international industrial change landscape, industrial automation is no longer simply a device for enhancing production effectiveness; it is a core column for constructing adaptable manufacturing systems and allowing data-driven decision-making.

As the “brain” of industrial control systems, the Programmable Logic Controller (PLC) holds a crucial placement. Nevertheless, with expanding production ranges, increasing process intricacies, and the deep assimilation of Internet of Things (IoT) technologies, standalone PLC systems often fail.

There is an immediate need to establish efficient, stable, and reliable interaction links between PLCs dispersed throughout different production lines and responsible for unique jobs, to achieve seamless information sharing, integrated equipment operation, and international optimization of production processes.

The typical “info silo” model has actually become a significant traffic jam impeding the advancement of clever production.

As an example, if a product packaging line’s PLC can not obtain real-time manufacturing information from the upstream loading line, it leads to rhythm inequalities. Likewise, if a robot control PLC can not share fault info with the main production line PLC, it lengthens downtime.

These concerns emphasize the important importance of inter-PLC communication. It not only serves as a bridge for information exchange at the equipment degree but likewise creates the basic basis for factory-wide and also enterprise-level data combination, evaluation, and decision-making.

PLC Interconnectivity: The Cornerstone and Core Value of Smart Manufacturing

Interaction between PLCs extends far beyond straightforward information transfer, it is the keystone for modern-day industrial automation systems to accomplish the adhering to core values:

Information Sharing and Transparency: Real-time manufacturing information (such as result, tools status, fault codes, etc) traded in between different PLCs supplies production monitoring with a detailed factory operational review. This forms the information foundation for large information analytics and anticipating upkeep, helping to reduce unexpected downtime and boost Overall Equipment Effectiveness (OEE).

Collaborative Operation and Process Optimization: Through interaction, multiple PLCs can collaboratively carry out intricate manufacturing jobs. As an example, on an automated assembly line, product feeding, handling, inspection, and product packaging might be regulated by different PLCs. Data synchronization among them guarantees smooth and efficient manufacturing flow.

Centralized Management and Remote Control: Inter-PLC communication enables main control rooms or managerial systems (such as SCADA, MES) to centrally check, readjust parameters, and remotely detect multiple PLCs. This significantly improves system maintainability and scalability, while minimizing functional and upkeep costs.

Adaptable Manufacturing and Rapid Response: In the face of rapidly transforming market needs, contemporary manufacturing facilities need nimble production abilities. PLC interconnectivity makes production line reconfiguration and adjustments extra flexible. Through remote setup and program downloads, brand-new production tasks can be rapidly adapted. Essentially, PLC interconnectivity is an important course to developing digital factories, enabling intelligent decision-making, and strengthening venture competition.

Thorough Analysis and Comparison of Core Communication Methods

The key communication techniques between PLCs consist of serial communication, identical interaction, and Industrial Ethernet communication. Comprehending their features is crucial for choosing the ideal remedy.

Serial Communication:

- Features: Transmits data bit by bit. Calls for fewer signal lines, suitable for longer distances.

- Advantages: Simple electrical wiring, reduced price, relatively better sound resistance.

- Limitations: Relatively slower transmission speed, minimal real-time capability.

- Typical Protocols: Modbus RTU/ASCII, PPI, custom-made RS-232/ RS-485 protocols, etc.

Parallel Communication:

- Qualities: Transmits information in bytes or words simultaneously over multiple data lines.

- Benefits: High transmission speed, strong real-time capacity.

- Limitations: Complex wiring, short transmission distance, greater price, susceptible to interference.

- Common Applications: Primarily used for short-distance, high-speed requirements, frequently in between PLC modules or between a PLC and details high-speed I/O components, much less frequently utilized as a mainstream approach for inter-PLC connectivity.

Industrial Ethernet Communication:

- Attributes: Based on standard Ethernet technology but maximized for effectiveness and real-time efficiency in industrial atmospheres. Uses the TCP/IP protocol suite, sustaining different network geographies such as star, bus, and ring.

- Benefits: High speed (100 Mbps/Gbps), big information ability, high network flexibility, supports several masters and servants, simple combination with IT networks, and excellent scalability.

- Limitations: Relatively higher initial investment, extra intricate arrangement.

Evaluation and Selection Guide for Mainstream Communication Protocols

Interaction procedures are the “language” of information exchange, specifying the style, timing, and error handling devices for information transmission. In inter-PLC interaction, selecting the ideal procedure is central to system layout.

Modbus Protocol

- Introduction: Modbus is an enduring, open, and extensively taken on serial communication protocol, sustaining physical user interfaces like RS-232 and RS-485. It has also evolved into Modbus TCP, which is based upon Ethernet.

- Features: Simple procedure framework, simple to apply and debug. Supports master-slave setting, where one master can handle several servants. Rich information kinds, consisting of coils and registers.

- Applications: Commonly used for interaction in between various PLC brands, or between PLCs and tools, sensors, HMIs, specifically in situations with less rigorous real-time needs or as a general-purpose interface.

PPI Protocol (Point-to-Point Interface)

- Overview: PPI is a serial communication protocol exclusive to Siemens S7-200 series PLCs, based upon the RS-485 physical layer.

- Qualities: Specific to Siemens S7-200 series PLCs, mostly made use of for program upload/download with programs software application (Step7-Micro/Win) and communication between S7-200 and HMIs. Supports master-slave setting.

- Applications: Limited to Siemens S7-200 series PLCs. In current mainstream S7-1200/ 1500 series, it has been largely superseded by PROFINET/Ethernet interaction.

PROFINET Protocol

- Summary: PROFINET is an industrial automation communication procedure developed by PROFIBUS & PROFINET International (PI), based on basic Ethernet.

- Characteristics: High-speed, strong real-time capability (sustaining IR_T and various other real-time courses), supports adaptable network topologies (line, star, ring), integrates analysis performances, and promotes easy tool management and design arrangement.

- Applications: Widely adopted by numerous PLC brand names such as Siemens and Beckhoff. It is the favored choice for complex, high-speed, and real-time-critical production lines (e.g., auto manufacturing, packaging machinery).

EtherNet/IP Protocol

- Overview: EtherNet/IP (Ethernet Industrial Protocol) is an industrial protocol developed by ODVA (Open DeviceNet Vendors Association), also based on standard Ethernet.

- Characteristics: Utilizes the Common Industrial Protocol (CIP) to unify control, safety, configuration, and diagnostic functionalities. Supports both Explicit Messaging and Implicit Messaging for flexible data exchange and high-performance real-time control.

- Applications: Widely used with Rockwell Automation’s Allen-Bradley PLCs and numerous other CIP-compliant devices. Dominant in the North American market.

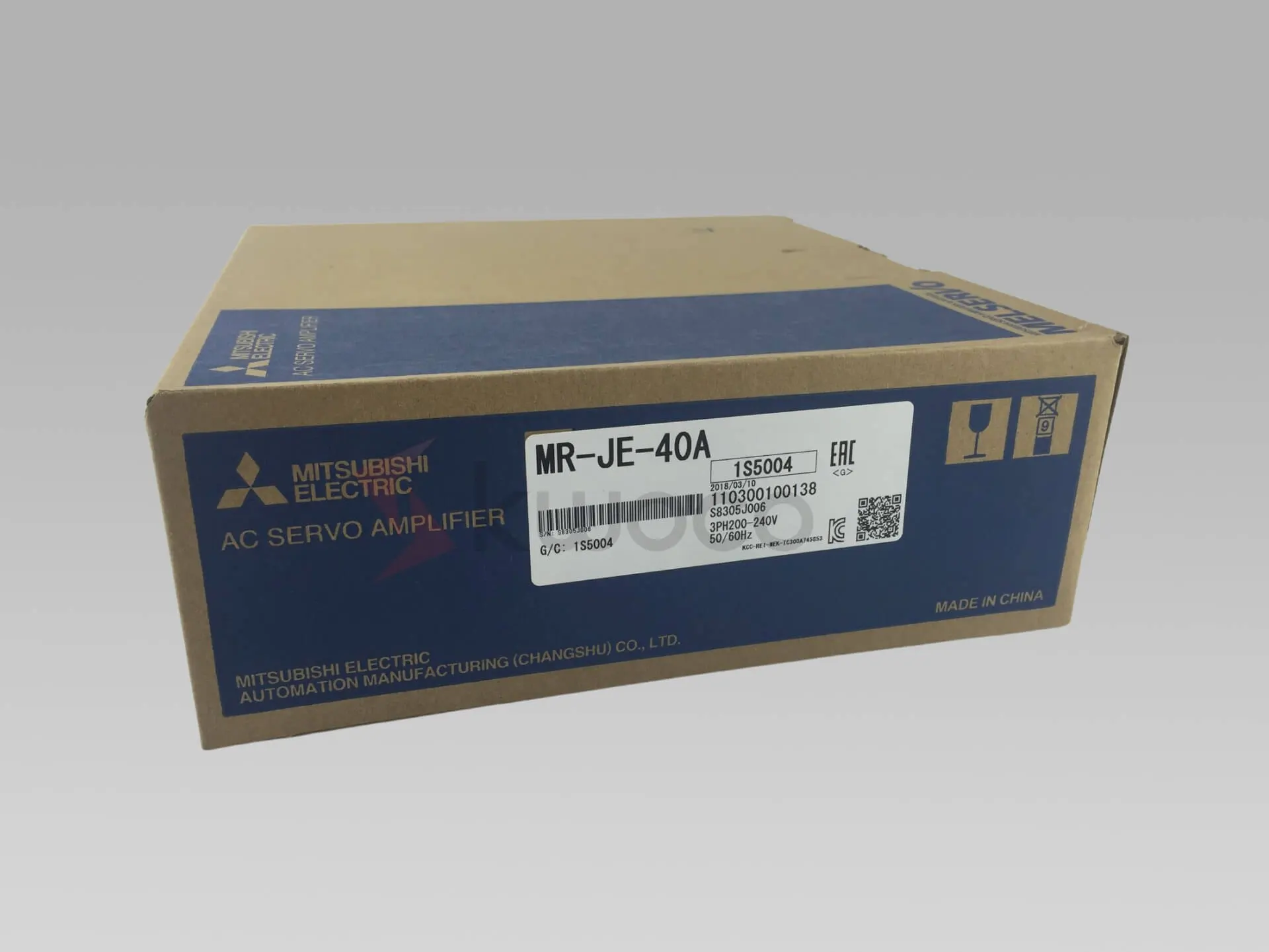

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

Communication between PLCs is the lifeline of modern industrial automation systems. This article has thoroughly explained its central role in smart manufacturing, delving into the characteristics and application scenarios of serial communication, parallel communication, and Industrial Ethernet.

Through comparative tables, it has highlighted the performance disparities among mainstream protocols like Modbus, PPI, PROFINET, and EtherNet/IP. We have also provided detailed PLC communication configuration steps and practical recommendations, emphasizing the importance of every stage from solution design to security protection.

Mastering and flexibly applying these communication technologies is not only an essential skill for industrial field engineers but also crucial for enterprises to maintain a leading edge and achieve sustainable development in a highly competitive market. By bridging data silos and embracing interconnectivity, we are stepping into a more intelligent and efficient industrial era.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is a Servo Motor and How Does It Work?

What is a Servo Motor and How Does It Work? When it comes to precision and control in industrial automation,

Everything You Need to Know About Contactors and How They Work

This comprehensive guide provides everything you need to know about contactors, including their types, applications, operating principles, and how they compare to relays. Whether you’re an engineer in a machinery and equipment factory, a manufacturer, or part of a factory solution company, understanding contactors is essential for optimizing your industrial automation processes.

Navigating the Future: Unpacking the Current State of the Industrial Automation Industry

The industrial automation industry is evolving at an unprecedented pace. This article delves into the current state of this dynamic sector, exploring the key trends, market size, and future projections. It’s a must-read because it provides a comprehensive overview of where the industry stands today and where it’s heading, offering valuable insights for anyone interested in or involved with industrial automation.