Introduction to Programmable Logic Controllers: Your Gateway to Industrial Automation

Table of Contents

1. What is a PLC (Programmable Logic Controller)?

A programmable logic controller (PLC) is a specialized industrial computer designed to automate industrial processes. The first PLC was developed to replace hard-wired relay logic systems, offering a more flexible and efficient solution.

I see PLCs as the brains behind many automated systems in factories and plants. They take inputs from various devices like sensors and switches, process the information based on a PLC program, and generate outputs to control machinery and equipment.

PLCs are widely used in industrial automation due to their robustness, reliability, and ability to withstand harsh industrial environments. They are designed to control and monitor processes with high precision, improving efficiency and reducing human error.

As an expert in industrial automation, I’ve seen how PLCs have revolutionized manufacturing, enabling complex operations to run seamlessly. The modular digital controller is equipped with a programmable memory for storing instructions and performing functions to control machines and processes.

2. How Does a PLC Work?

A PLC operates in a continuous cycle, scanning its program and updating outputs based on the current inputs. This process involves reading the input status, executing the control logic written in the programming language, and then updating the output status accordingly. The PLC takes signals from input devices and makes decisions based on the programmed logic.

PLC work revolves around processing information and making decisions in real-time. For instance, if a sensor detects a product on a conveyor belt, the PLC can trigger an actuator to move the product to the next stage.

I find that the ability of PLCs to process information quickly and accurately is what makes them so valuable in industrial automation. The CPU (Central Processing Unit) is the core component that executes the program and makes these decisions.

3. What are the Basic Components of a PLC?

The basic components of a PLC include the CPU (Central Processing Unit), input and output modules, power supplies, and a programming device. The CPU is the brain of the PLC, executing the program and processing data. Input modules receive signals from external devices, while output modules send control signals to the machinery.

| Component | Description |

|---|---|

| CPU | Executes the program and processes data. |

| Input Module | Receives signals from external devices. |

| Output Module | Sends control signals to machinery. |

| Power Supplies | Provides power to the PLC components. |

| Programming Device | Used to create and modify PLC programs. |

In my experience, understanding these components is crucial for anyone working with PLCs. For example, the input module can be either digital or analog, depending on the type of signal it receives. Similarly, output modules can control various devices, such as motors, valves, and lights.

4. What are the Different Types of PLCs?

There are primarily two types of PLCs: compact and modular. Compact PLCs are all-in-one units with integrated inputs and outputs, suitable for small-scale applications. Modular PLCs, on the other hand, consist of separate modules that can be configured and expanded as needed.

Modular PLCs offer greater flexibility, allowing users to customize the system based on their specific requirements. I often recommend modular PLCs for complex systems where scalability is important. For example, a modular PLC might include separate modules for digital inputs, analog inputs, digital outputs, and analog outputs, each tailored to different types of sensors and actuators.

5. How is PLC Programming Done?

PLC programming involves creating a set of instructions that tell the PLC how to operate. This is typically done using specialized programming software provided by the PLC manufacturer, the PLC takes these instructions and execute them sequentially. Programming a PLC requires an understanding of the process being automated and the desired control logic.

The programming language for PLCs can vary, but the most common is ladder logic, a graphical language that resembles relay logic diagrams. Other PLC programming languages include function block diagram (FBD), structured text (ST), and sequential function chart (SFC). In my work, I’ve found that ladder logic is often preferred for its simplicity and ease of understanding, especially for technicians familiar with relay logic.

6. What are the Common PLC Programming Languages?

PLC programming languages provide different ways to create control programs. Ladder logic is the most widely used PLC programming language, known for its visual representation of relay logic. Function block diagram (FBD) is another graphical language that uses blocks to represent functions and their interconnections.

Structured text (ST) is a high-level language similar to Pascal, offering more advanced programming capabilities. Sequential function chart (SFC) is used for complex processes that involve multiple steps and transitions. I’ve used all these languages in various projects and appreciate the flexibility they offer. For instance, structured text is excellent for complex calculations, while ladder logic is ideal for simple on/off control.

- Ladder Logic: Resembles electrical relay logic diagrams, making it intuitive for those familiar with electrical systems.

- Function Block Diagram (FBD): Uses graphical blocks to represent functions, suitable for complex logic.

- Structured Text (ST): A high-level language similar to Pascal, used for advanced programming tasks.

- Sequential Function Chart (SFC): Ideal for processes with multiple steps and transitions.

7. What is Ladder Logic and How is it Used in PLC Programming?

Ladder logic is a graphical programming language that represents control logic in a way that resembles electrical relay logic diagrams. It uses contacts and coils to represent inputs and outputs, respectively. Ladder logic is widely used because it is easy to understand and visualize.

In ladder logic, a rung represents a single control statement, with contacts on the left (inputs) and coils on the right (outputs). The PLC executes each rung sequentially, updating the outputs based on the state of the inputs. I often use ladder logic for simple control tasks, such as starting and stopping motors or controlling lights. For example, a simple rung might check if a start button is pressed (input) and then energize a motor (output).

Here is a simple example of a ladder logic rung:

Start Button (Input) –| |– Motor (Output)

8. How Do PLCs Interface with Other Devices and Systems?

PLCs can interface with a wide range of devices and systems using various communication protocols. Input and output modules allow PLCs to connect to sensors, actuators, and other field devices. PLCs can also communicate with other PLCs, HMIs (Human Machine Interfaces), and SCADA (Supervisory Control and Data Acquisition) systems.

For instance, a PLC might use Modbus to communicate with a remote I/O module or EtherNet/IP to connect to a SCADA system. I’ve worked on projects where PLCs were integrated into larger industrial internet of things (IIoT) networks, enabling remote monitoring and control. The interface capabilities of PLCs are crucial for building interconnected and intelligent automation systems.

9. What are the Applications of PLCs in Industrial Automation?

PLC applications are vast and varied, spanning across different industries and processes. PLCs are used to automate everything from simple machines to complex production lines. Some common PLC applications include controlling conveyor systems, managing HVAC systems, operating packaging machines, and monitoring industrial processes.

In my experience, PLCs are particularly useful in applications that require high reliability and precision. For example, in a food processing plant, a PLC can control the temperature, pressure, and flow rate of ingredients to ensure consistent product quality. PLCs can also be used in safety-critical applications, such as emergency shutdown systems, where their reliability is paramount. They used to control a wide variety of machines and processes, ensuring they operate correctly and efficiently.

Here are some examples of PLC applications:

- Conveyor systems

- HVAC systems

- Packaging machines

- Robotic arms

- Water treatment plants

- Emergency shutdown systems

10. How to Troubleshoot PLC Systems?

Troubleshooting PLC systems involves identifying and resolving issues that prevent the system from operating correctly. Common problems include faulty inputs or outputs, programming errors, and communication failures. Effective troubleshooting requires a systematic approach and a good understanding of the PLC system.

I always start by checking the PLC’s diagnostic indicators and error logs. Most PLCs have built-in diagnostics that can provide valuable information about the system’s status. Next, I verify the inputs and outputs using a multimeter or a programming device to ensure they are functioning correctly. If the problem persists, I review the PLC program for errors or inconsistencies.

Here are some tips for troubleshooting PLC systems:

- Check the PLC’s diagnostic indicators and error logs.

- Verify inputs and outputs using a multimeter.

- Review the PLC program for errors.

- Check for loose connections or damaged wiring.

- Ensure the power supply is stable.

- Test communication links with other devices.

Frequently Asked Questions

While both PLCs and microcontrollers are used for control applications, they differ in their design and intended use. PLCs are designed for industrial environments, offering robustness, reliability, and ease of programming. Microcontrollers, on the other hand, are typically used in embedded systems and consumer electronics. I often recommend PLCs for industrial applications due to their superior durability and specialized features.

Yes, PLCs can be used for home automation, but they are generally overkill for such applications. Home automation systems typically use simpler and more cost-effective solutions, such as smart home hubs and microcontrollers. However, for complex or large-scale home automation projects, a PLC might be a viable option.

Ladder logic offers several advantages, including its simplicity, ease of understanding, and visual representation of control logic. It is particularly useful for technicians familiar with electrical relay logic, making the transition to PLC programming easier. I find that ladder logic is an excellent choice for simple to moderately complex control tasks.

Choosing the right PLC depends on several factors, including the complexity of the application, the number of inputs and outputs, the required processing speed, and the communication needs. I recommend starting by defining the specific requirements of your application and then selecting a PLC that meets those needs. Consider factors such as scalability, programming language support, and environmental conditions.

SCADA (Supervisory Control and Data Acquisition) systems are used to monitor and control industrial processes from a central location. They often work in conjunction with PLCs, providing a higher-level interface for operators and managers. SCADA systems can collect data from multiple PLCs, display real-time process information, and allow operators to make adjustments or issue commands. I see SCADA as an essential tool for managing complex automation systems, providing valuable insights and control capabilities.

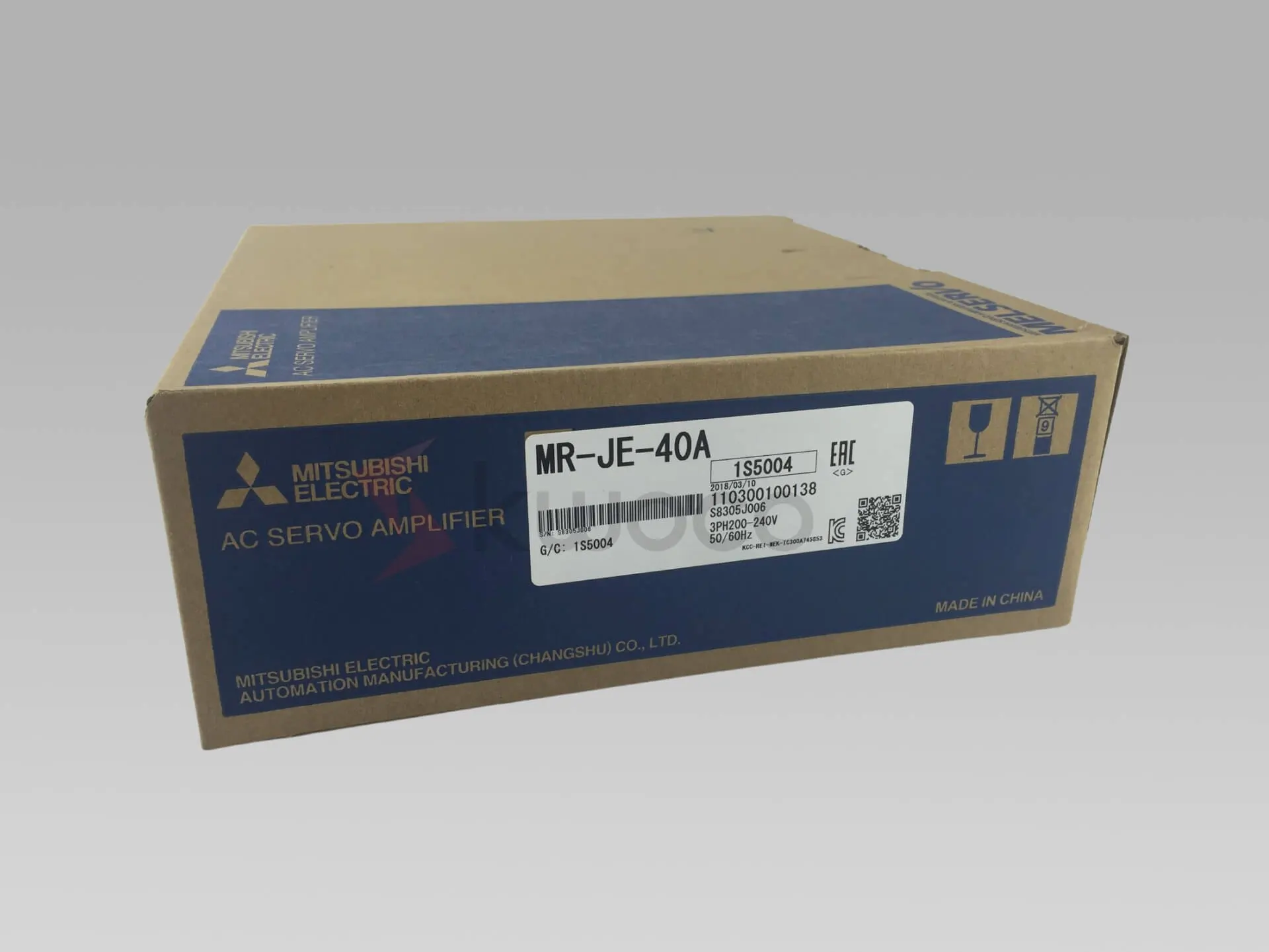

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servo – in stock, ready now!

Conclusion

- PLCs are essential components of modern industrial automation systems.

- Understanding the different types of PLCs and their programming languages is crucial for effective automation.

- Ladder logic remains a popular choice for PLC programming due to its simplicity and ease of use.

- PLCs can interface with a wide range of devices and systems, enabling complex automation solutions.

- Troubleshooting PLC systems require a systematic approach and a good understanding of the system’s components and programming.

- Choosing the right PLC depends on the specific requirements of the application.

- You can familiarize yourself with the world of programmable logic controllers by exploring Mitsubishi PLC, Schneider PLC, and Mitsubishi HMI to understand their capabilities and how they can enhance industrial automation.

- For more advanced automation needs, integrating Delta Servo and Schneider Inverter can provide precise control and energy efficiency in your systems.

- By understanding and utilizing these technologies, you can significantly improve the efficiency and productivity of your industrial processes.

By leveraging my expertise in industrial automation and control products, I aim to provide solutions that meet the needs of machinery and equipment factories, manufacturers, and factory solution companies.

My goal is to help you achieve seamless automation, enhance productivity, and drive success in your operations. Contact me today to learn more about how we can transform your industrial processes with advanced PLC solutions.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Top 10 Omron PLC Suppliers in the United States

Top 10 Omron PLC Suppliers in the United States Omron PLC is widely used in the US market, especially in

Exploring the Power of Sensors: Types, Uses, and Applications

Sensors are all around us, working quietly behind the scenes to make our lives more convenient, efficient, and safe. From turning on lights when we enter a room to ensuring safety in our vehicles, sensors are integral to modern technology.

10 Things You Need to Know About Omron CPU Type

10 Things You Need to Know About Omron CPU Type As an engineer with years of experience in the industrial