What Is a PLC Panel? A Guide to Electrical Automation

Table of Contents

What Is a PLC Panel in Industrial Automation?

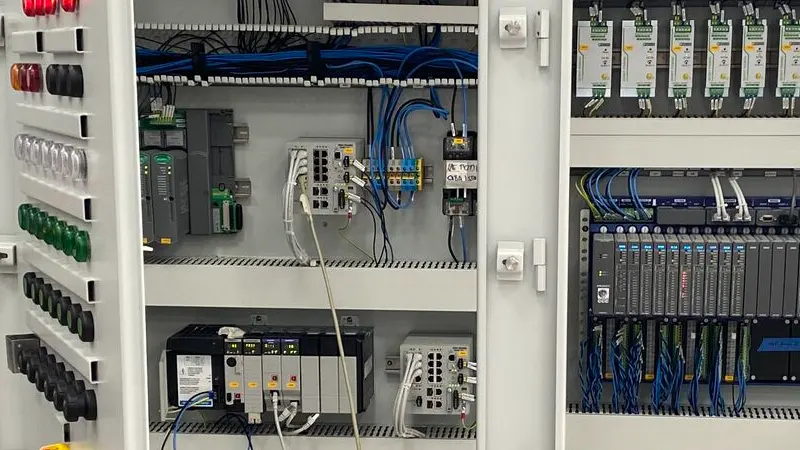

A PLC panel, or Programmable Logic Controller panel, is a type of control panel that houses a PLC and other essential components required for controlling and automating machinery in industrial settings. Essentially, it’s a box that contains all the necessary electrical equipment to control and monitor various industrial processes.

PLC panels are used extensively in industrial automation to automate and streamline operations. By integrating input from sensors and devices, the PLC processes data using a predefined programme and triggers the appropriate output actions. This enables precise control over complex processes, making operations more efficient and reliable.

How Does a PLC Control Panel Work?

At the heart of a PLC control panel is the Programmable Logic Controller itself—a specialized industrial computer designed to handle control processes.

Here’s how it functions:

- Input Modules: These receive signals from input devices like sensors, switches, and buttons.

- Central Processing Unit (CPU): The CPU processes the inputs based on the programme loaded into the PLC, making decisions in real-time.

- Output Modules: After processing, the PLC sends commands to output devices such as motors, valves, and actuators.

This process allows the PLC to control various aspects of machinery, ensuring smooth and efficient operation. The input and output modules facilitate communication between the PLC and the physical equipment, enabling precise control over the entire system.

| Component | Function |

|---|---|

| Input Modules | Receive signals from field devices like sensors and switches |

| Central Processing Unit (CPU) | Processes inputs using the loaded programme and makes real-time decisions |

| Output Modules | Send commands to output devices such as motors and actuators |

This integrated system allows for seamless automation of industrial processes, enhancing efficiency and reliability.

Designing a PLC Panel: Key Components and Considerations

Designing a PLC panel involves selecting the right components and configuring them to meet the application’s specific needs. Key panel components include:

- PLC and Other Components: The core of the system, including the PLC, input and output modules, and communication modules for remote monitoring.

- Power Supplies: Provide the necessary voltage to the PLC and other components.

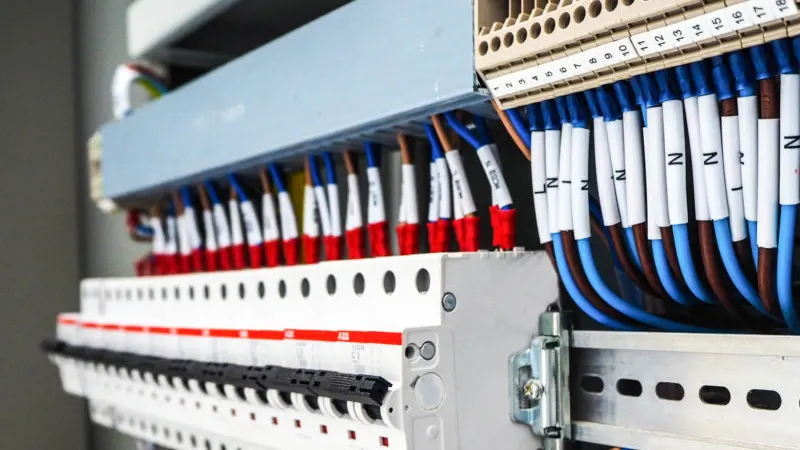

- Wiring: Connects all internal components, ensuring efficient communication and power distribution.

- Enclosure: An enclosure or electrical panel that houses all the components, protecting them from environmental factors.

- Circuit Breakers: Safety devices that protect the panel from electrical overloads.

- Human-Machine Interface (HMI): Devices that allow operators to interact with the PLC, such as touchscreens or control panels.

When designing a PLC panel, it’s crucial to consider factors like space, environmental conditions, and compliance with safety standards. The initial layout should facilitate easy access for maintenance and future expansion.

For those looking to select high-quality PLCs, brands like Mitsubishi PLC and Omron PLC offer reliable solutions tailored to various industrial needs.

Benefits of Using PLC Panels in Industrial Applications

Implementing PLC panels in industrial settings offers numerous advantages:

- Precision and Efficiency: PLCs provide precise control over processes, enhancing productivity.

- Flexibility: The programme can be easily modified to accommodate changes in the production process.

- Reliability: Designed for harsh industrial settings, PLCs are robust and dependable.

- Scalability: PLC systems can be expanded with additional modules to meet growing operational demands.

- Remote Monitoring: Modern PLCs support remote monitoring, allowing for real-time supervision and adjustments from afar.

By utilizing PLC panels, industries can achieve control solutions that improve operational efficiency and reduce downtime. The use of PLC systems is particularly beneficial in critical infrastructure where reliability is paramount.

To enhance operator interaction, integrating an HMI like the Omron HMI can provide intuitive control interfaces, further optimizing industrial processes.

Getting Started with PLC Programming and Wiring

Embarking on PLC programming may seem daunting, but with the right approach, it becomes manageable:

- Define the Desired Control: Understand what you aim to achieve with the PLC system.

- Choosing the Right PLC: Selection depends on the application’s requirements, such as the number of input and output points.

- Develop the Programme: Create the control logic using programming languages like Ladder Logic.

- Design the Wiring: Plan the wiring to connect all electrical components efficiently.

- Test and Troubleshoot: Verify the system’s functionality and make necessary adjustments.

For comprehensive guidance, the Guide to Electrical Automation is an excellent resource to deepen your understanding.

Proper wiring and programming are crucial for system reliability. Working with reputable brands like Schneider PLC can provide additional support and assurance in your automation projects.

Frequently Asked Questions

A PLC panel is a type of control panel that houses a Programmable Logic Controller and other electrical components necessary for automating and controlling machinery. It’s important because it centralizes control, improves efficiency, and enhances the reliability of industrial processes.

Unlike traditional control systems that may use hardwired logic, a PLC control panel utilizes a programmable approach, allowing for easier modifications and updates. This flexibility enables industries to adapt quickly to changing operational needs.

Yes, PLC panels are highly customizable. The design and components can be tailored to meet specific industrial requirements, ensuring optimal performance for the intended application.

Wiring is essential for connecting the PLC and other components within the panel. It ensures that signals are correctly transmitted between input devices, the PLC, and output devices, enabling the system to function properly.

Human-Machine Interfaces (HMIs) allow operators to interact with the PLC, providing real-time data visualization and control options. Integrating an HMI enhances usability and enables more efficient monitoring and adjustments.

For more information or assistance with PLC panels and automation solutions, feel free to contact us.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- PLC control panels are integral to modern industrial automation, providing centralized control and monitoring.

- They consist of a PLC and other electrical components housed within an enclosure.

- Designing a PLC panel requires careful consideration of components, wiring, and safety features.

- Implementing PLC panels offers benefits like increased efficiency, precise control, and flexibility.

- Getting started with PLC programming involves understanding hardware and software, with resources available to guide you.

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Why Choose Allen-Bradley PLCs for Your Project?

Why Choose Allen-Bradley PLCs for Your Project? Struggling with selecting the right PLC for your engineering projects? You’re not alone.

What is a Servo Motor and How Does It Work?

What is a Servo Motor and How Does It Work? When it comes to precision and control in industrial automation,

The Core Engine of Industrial Automation: A Comprehensive Guide to PLC Principles, Classification, and Selection

With the fast innovation of Sector 4.0 and Smart Production, the PLC (Programmable Logic Controller) has actually come to be the essential “digital brain” of contemporary commercial assembly line.