Can I use PC instead of PLC?

Table of Contents

Understanding PLCs and PCs in Industrial Automation

Before diving into the PC vs PLC debate, it’s essential to understand what each device brings to the table in industrial automation.

What is a Programmable Logic Controller (PLC)?

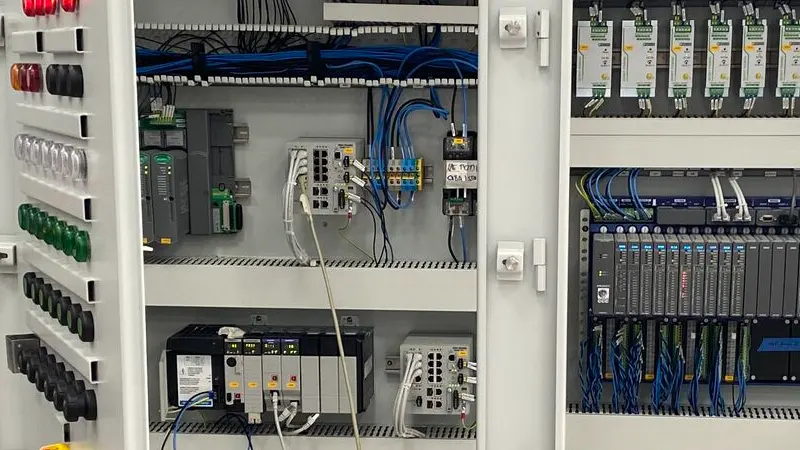

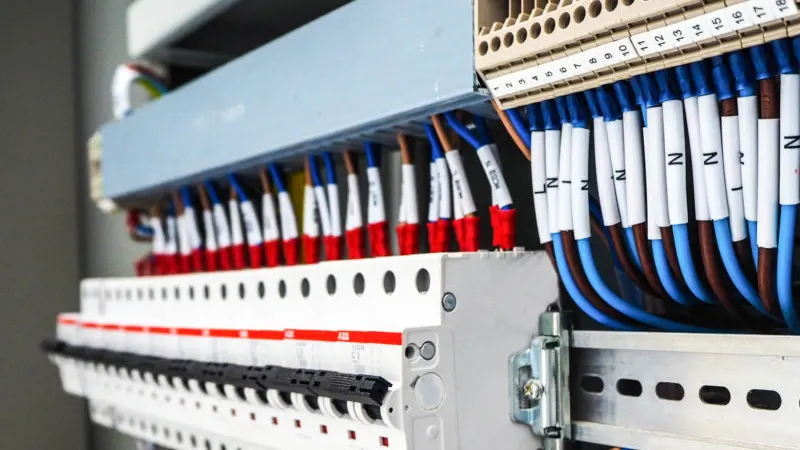

A Programmable Logic Controller (PLC) is an industrial computer specifically designed for controlling industrial processes and machinery. PLCs were designed to replace traditional relay panels and switch boxes, offering programmable flexibility.

They are built to withstand harsh industrial environments, including extreme temperatures, shock and vibration, and electrical noise.

Key Features of PLCs:

- Rugged Design: Ideal for harsh industrial conditions.

- Real-Time Operating System: Ensures timely and deterministic control.

- Programming Languages: Typically programmed using ladder logic or other languages specified in the IEC standards.

- Reliability: Minimal downtime and less vulnerable to malware.

What is a PC in Industrial Automation?

An Industrial PC is a personal computer adapted for the industrial environment. It offers greater processing power and flexibility compared to a PLC.

Key Features of Industrial PCs:

- Higher Processing Throughput: Suitable for complex computations and data handling.

- Standard Operating Systems: Runs on Windows, Linux, or other systems.

- Programming Languages: Can be programmed using high-level languages like C++ or Python.

- Expansion Capabilities: Built with expansion slots and feature various COM ports for connectivity.

However, industrial PCs have a higher initial cost and may be more vulnerable to malware attacks, requiring current antivirus software and firewalls.

PC vs PLC: Can a PC Replace a PLC?

The major difference between PLCs and industrial PCs lies in their design and purpose.

Reliability in Harsh Environment

- PLCs are designed for harsh industrial environments, making them resistant to shock and vibration, dust, and moisture.

- Industrial PCs are robust but may not endure harsh industrial conditions as effectively as PLCs.

Operating Systems and Software

- PLCs use a real-time operating system optimized for control tasks.

- Industrial PCs run standard operating systems, which may be vulnerable to malware and require regular updates and security measures.

Programming and Control Tasks

- PLCs are typically programmed using ladder logic, familiar to electrical technicians.

- Industrial PCs use programming languages like C, allowing for versatile applications but with increased complexity.

Maintenance and Downtime

- PLCs do not require antivirus programs or registry cleaners, reducing maintenance.

- A PC may require regular software updates and security checks. If compromised, it could be down for days.

Cost Considerations

- PLCs generally have a lower initial cost.

- Industrial PCs have a higher initial investment due to advanced capabilities.

When to Choose PLC-Based Control Systems

PLC-based control systems are ideal when:

- Operating in harsh industrial environments.

- Tasks are straightforward control tasks.

- High reliability and minimal downtime are crucial.

- Simpler programming with ladder logic is preferred.

Example Use Cases:

- Controlling assembly lines.

- Monitoring and controlling industrial machines.

- Managing industrial processes that require consistent reliability.

When to Opt for PC-Based Control Systems

PC-based control systems are suitable when:

- Complex data processing and visualization are needed.

- Integration with other software systems is required.

- Processing throughput is a priority.

- Flexibility in programming and expansion is desired.

Example Use Cases:

- Advanced data analysis in manufacturing.

- Complex automation requiring machine vision.

- Applications needing connectivity with enterprise systems.

Can You Use Both PLCs and Industrial PCs Together?

Yes, it’s common to use both PLCs and industrial PCs in an automation system. This hybrid approach leverages the strengths of both:

- PLCs handle real-time control tasks and interface with machinery.

- Industrial PCs manage higher-level functions like data processing, user interfaces, and network communications.

This combination ensures robust control while providing the flexibility and processing power of a PC.

Frequently Asked Questions

While it’s possible, replacing a PLC with an industrial PC depends on the application. PLCs are designed for reliability in harsh industrial environments, making them indispensable for critical control operations. A PC may not offer the same level of durability and might be more susceptible to security threats.

Industrial PCs are much more vulnerable to malware attacks due to their standard operating systems. They require current antivirus software and firewalls. In contrast, PLCs do not require such measures, making them more robust against cyber threats.

Yes, because industrial PCs run on standard operating systems, they need regular updates, security patches, and maintenance like any other PC. PLCs have a lower maintenance burden as they don’t require antivirus programs or registry cleaners.

Typically, PLCs have a lower initial cost compared to industrial PCs, which have a higher initial investment due to their advanced capabilities. However, the total cost should be evaluated based on the specific requirements and scalability of the automation system.

Absolutely. PLCs and industrial PCs can communicate using standard industrial communication protocols, allowing for integrated systems where each handles tasks suited to its strengths.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

In the PC vs PLC debate, the choice depends on your specific application and requirements. For environments where reliability and durability are paramount, and the control tasks are straightforward, a PLC is designed to meet those needs effectively.

If your application demands higher processing capabilities and greater flexibility, and you can manage the associated maintenance, an industrial PC uses its strengths to provide a powerful solution.

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

PLC Instruction Failures: A Troubleshooting Guide

In the domain name of modern industrial automation, the Programmable Logic Controller (PLC) plays an important role. It serves as the “brain” of the automation system, managing every stage of the manufacturing procedure by implementing a collection of exact guidelines.

Do Photoelectric Sensors Need Reflectors? Expert Insights

One question that comes up frequently is: Does a photoelectric sensor need a reflector? The answer isn’t a simple yes or no—it depends on the type of sensor and the application’s requirements. Let’s delve into the details to clarify this topic.

Transforming the Future of Industrial Automation: Insights for Automation Engineers

Step into a world where machines think and processes are automated. Industrial automation is transforming industries, reshaping how we manufacture, control, and deliver products. This article explores the evolution, benefits, and future of industrial automation, providing valuable insights into how it’s transforming the way we live and work.