Demystifying Magnetic Switches: A Comprehensive Guide for Industrial Applications

Table of Contents

1. What is a Magnetic Switch?

A magnetic switch is an electrical switch that operates based on the presence of a magnetic field. Unlike a conventional mechanical switch, which requires physical contact to open or close, a magnetic switch is triggered by the proximity of a magnet.

As a leading provider in industrial automation, I’ve seen firsthand how these devices are integral to modern machinery. When a magnet approaches the switch, the magnetic field causes the internal components, often a reed switch inside a sealed glass tube, to make or break the electrical circuit.

Magnetic switches are widely used in various applications, including security systems, industrial machinery, and even household appliances. For example, a magnetic switch mounted to a door frame with a magnet on the door can detect the opening or closing of the door.

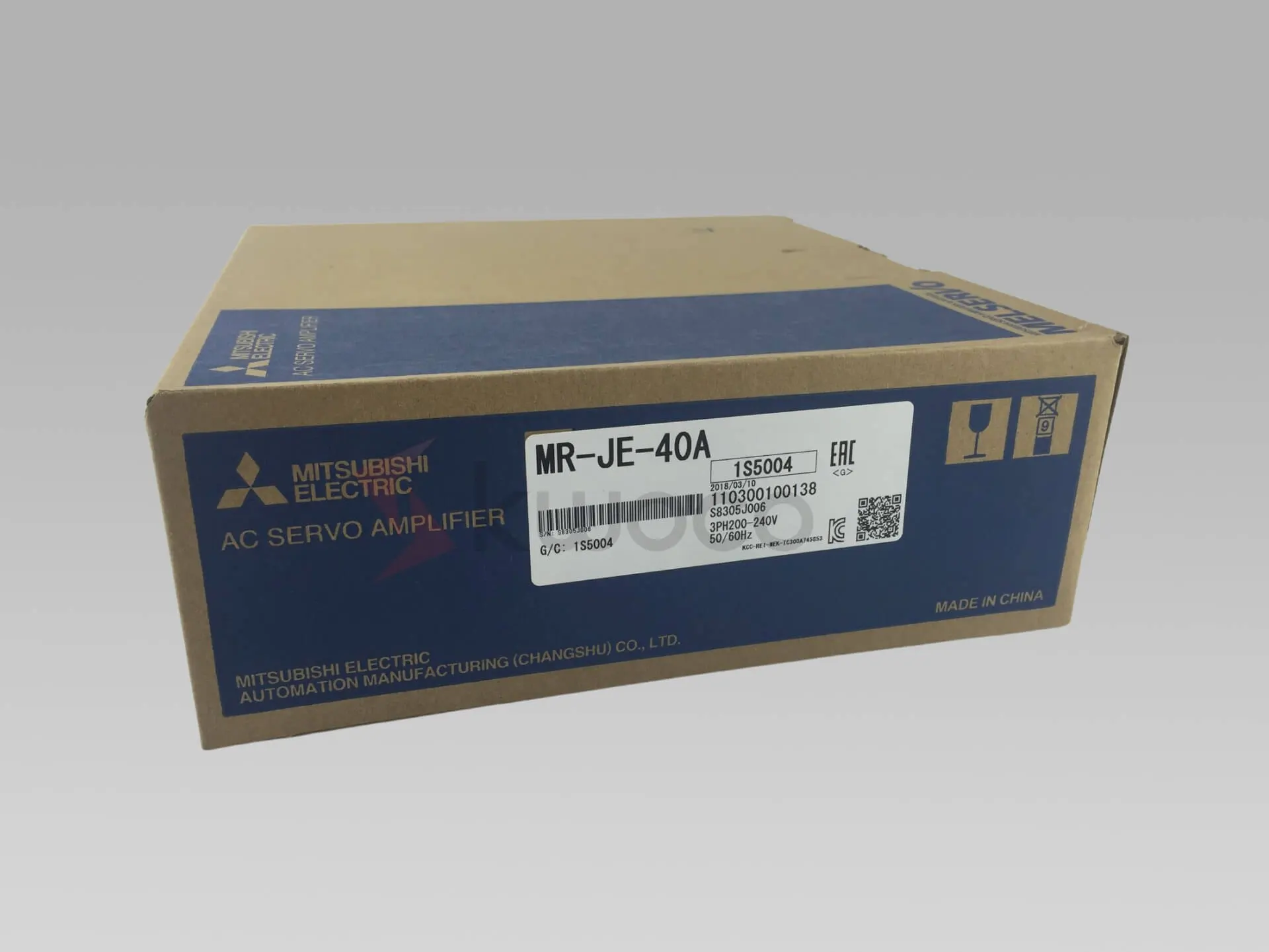

The versatility and reliable performance of magnetic switches make them an excellent choice for many electrical devices. We offer a range of these components, including Omron PLC and Mitsubishi PLC, to ensure precise control and high performance in your systems.

2. How Do Magnetic Switches Differ from Mechanical Switches?

Magnetic switches and traditional mechanical switches both serve to control the flow of electricity, but they operate very differently. Mechanical switches rely on physical contact to complete or interrupt an electrical circuit.

For instance, a light switch uses mechanical parts that you manually flip to turn a light on or off. In contrast, magnetic switches rely on the magnetic field generated by a permanent magnet to operate. They offer several advantages over their mechanical counterparts, such as greater reliability, longevity, and resistance to wear and tear.

One key difference is the absence of physical contact in magnetic switches. This reduces the risk of mechanical failure and extends the lifespan of the switch. Additionally, magnetic switches can be completely sealed inside a protective casing, making them ideal for use in harsh environments where dust, moisture, or corrosive substances are present.

Here at our manufacturing plant, we use Omron sensors and magnetic switches to maintain high efficiency and safety standards. The ability of magnetic switches to operate without direct contact makes them particularly useful in safety devices and automation systems.

3. What Are the Main Types of Magnetic Switches?

There are several types of magnetic switches, each designed to meet specific needs. The most common type is the reed switch, which consists of two ferromagnetic reeds enclosed in a glass envelope. When a magnetic field is applied, the contacts of the reed switch either close (normally open) or open (normally closed), depending on the configuration.

Another type is the Hall effect sensor, which uses a semiconductor to detect changes in the magnetic field. The type used often depends on the conditions and what the switch is intended for.

Magnetic switches can also be categorized based on their application. For instance, magnetic switches used in alarm systems are often designed to trigger an alarm when a door or window is opened.

In contrast, magnetic switches in industrial automation may be used to sense the position of a machine part or to control the operation of equipment such as computers. Our products, including Schneider PLC and Mitsubishi HMI, incorporate advanced magnetic switches to ensure precise control and seamless operation.

4. How Do Magnetic Switches Work in an Alarm System?

In an alarm system, magnetic switches are crucial for detecting unauthorized entry. Typically, a magnetic switch is mounted on a door or window frame, and a magnet is attached to the door or window itself.

When the door or window is closed, the magnet is nearby the switch, keeping the alarm circuit in its normal state (normally closed or normally open). If the door or window is opened, the magnet moves away from the switch, causing the magnetic field to weaken and the switch to change state.

This change in state triggers the alarm, alerting you to a potential breach. The simplicity and reliability of magnetic switches make them ideal for security applications. They can be easily integrated into existing alarm systems and offer a high level of security.

Our customers, particularly machinery and equipment factories and factory solution companies, rely on our products, such as Schneider HMI and Omron HMI, to enhance their security systems with magnetic switches.

5. What Are the Benefits of Using Magnetic Switches in Industrial Automation?

Magnetic switches offer numerous benefits in industrial automation. One of the most significant advantages is their ability to operate without physical contact, which minimizes wear and tear and extends the lifespan of the switch.

This non-contact operation also makes magnetic switches ideal for use in environments where dust, debris, or other contaminants are present, as there are no exposed moving parts that can be affected.

Another benefit is the rapid trigger response of magnetic switches. When a magnet approaches, the switch activates almost instantaneously, providing precise control over machinery and processes.

This is particularly important in high-speed automation systems where timing is critical. Our company leverages these benefits by incorporating magnetic switches into our industrial control products. For example, our Delta Servo systems utilize magnetic switches to ensure accurate positioning and movement.

6. How Do You Choose the Right Magnetic Switch for Your Application?

Choosing the right magnetic switch for your application requires careful consideration of several factors. First, you need to determine whether you need a normally open or normally closed configuration.

This will depend on how you want the switch to behave when the magnet is nearby or far away. You also need to consider the strength of the magnetic field required to activate the switch and the distance at which the switch will be mounted from the magnet.

Additionally, you should evaluate the environmental conditions in which the switch will operate. If the environment is harsh, with high levels of dust, moisture, or temperature fluctuations, you will need a magnetic switch that is designed to withstand these conditions.

Our team is ready to assist you in selecting the right magnetic switch for your needs, whether you need a simple reed switch or a more advanced Hall effect sensor. We offer a wide range of products, including magnetic components and safety devices, to meet the diverse needs of our clients.

7. Can Magnetic Switches Be Used in Harsh Environments?

Yes, magnetic switches are well-suited for use in harsh environments. Their sealed design protects the internal components from dust, moisture, and other contaminants, ensuring reliable performance even under challenging conditions.

This makes them an excellent choice for industries such as manufacturing, where exposure to harsh elements is common.

The ability of magnetic switches to operate without physical contact also makes them resistant to wear and tear caused by mechanical friction. This is particularly beneficial in environments where frequent switching is required.

Our industrial automation solutions often incorporate magnetic switches designed to withstand extreme environmental conditions, providing our clients with durable and long-lasting products. For instance, our magnetic switches are used in outdoor settings where they are exposed to varying weather conditions, yet they continue to perform reliably.

8. What Role Do Magnetic Switches Play in Safety Systems?

Magnetic switches play a critical role in safety systems by providing a reliable means of detecting changes in position or status. For example, they can be used to ensure that safety guards or doors on machinery are properly closed before the equipment can be operated.

When the guard or door is open, the magnetic switch detects the absence of the magnet and prevents the machine from starting, thus protecting workers from potential hazards.

In addition to preventing machinery from operating when safety features are not engaged, magnetic switches can also be used to trigger alarms or emergency stops in the event of a safety breach.

This rapid response capability is essential for maintaining a safe working environment. Our safety devices utilize magnetic switches to provide an additional layer of protection, ensuring that our clients’ operations are as safe as possible.

9. How Do Magnetic Switches Enhance the Efficiency of Control Systems?

Magnetic switches enhance the efficiency of control systems by providing accurate and reliable feedback on the position or status of various components. This information is crucial for the precise control of machinery and processes, enabling automation systems to operate smoothly and efficiently.

For example, in a conveyor system, magnetic switches can be used to detect the presence of products at specific points along the line. This information can be used to control the speed of the conveyor, start or stop other machinery, or divert products to different paths.

The precise and rapid trigger response of magnetic switches ensures that these operations are performed accurately and efficiently. Our control systems incorporate advanced magnetic switches to provide our clients with high-performance automation solutions.

10. What Innovations Are Emerging in Magnetic Switch Technology?

Innovation in magnetic switch technology continues to drive improvements in performance, reliability, and versatility. One area of development is the miniaturization of magnetic switches, making them smaller and more compact without sacrificing performance.

This allows for greater flexibility in their application, particularly in devices where space is limited.

Another area of innovation is the integration of magnetic switches with other technologies, such as wireless communication and the Internet of Things (IoT). This enables remote monitoring and control of magnetic switches, providing real-time data and enhancing the capabilities of automation systems.

Our company is at the forefront of these developments, continuously researching and implementing new technologies to improve our products and provide our clients with cutting-edge solutions.

Data: Magnetic Switch Usage Statistics

| Industry | Usage Rate (%) |

|---|---|

| Manufacturing | 75 |

| Security Systems | 80 |

| Automotive | 60 |

| Medical Devices | 55 |

| Consumer Electronics | 40 |

This table shows the usage rate of magnetic switches across various industries, highlighting their widespread adoption and importance in modern technology.

Frequently Asked Questions

A magnetic switch is an electrical switch that operates based on the presence of a magnetic field. Unlike mechanical switches, which require physical contact to open or close, magnetic switches are triggered by the proximity of a magnet. This non-contact operation reduces wear and tear and increases the lifespan of the switch.

In alarm systems, a magnetic switch is typically mounted on a door or window frame, with a magnet on the door or window. When closed, the magnet keeps the switch in its normal state. If opened, the magnet moves away, changing the switch’s state and triggering the alarm.

Magnetic switches offer several benefits in industrial automation, including non-contact operation, which reduces wear and tear, and rapid trigger response, which enables precise control of machinery. They are also resistant to harsh environments and provide reliable performance.

Yes, magnetic switches are well-suited for harsh environments. Their sealed design protects internal components from dust, moisture, and other contaminants, ensuring reliable performance even under challenging conditions.

Choosing the right magnetic switch involves considering factors such as whether you need a normally open or normally closed configuration, the strength of the magnetic field required for activation, the distance between the switch and magnet, and the environmental conditions.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- Magnetic switches are electrical switches that operate based on the presence of a magnetic field.

- They offer significant advantages over mechanical switches, including non-contact operation, resistance to harsh environments, and rapid trigger response.

- Magnetic switches are widely used in various applications, including alarm systems, industrial automation, and safety devices.

- Choosing the right magnetic switch involves considering factors such as configuration, magnetic field strength, and environmental conditions.

- Innovations in magnetic switch technology continue to improve performance, reliability, and versatility.

By understanding the principles and benefits of magnetic switches, you can make informed decisions about their use in your applications, ensuring optimal performance and efficiency. Whether you need assistance with selecting the right magnetic switch or integrating it into your system, our team is ready to assist you.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Proximity Sensors: Inductive & Capacitive Explained

This article dives deep into the world of industrial sensors, specifically focusing on inductive, capacitive, and proximity types. Understanding how these sensors work, their applications, and their advantages is crucial for optimizing your manufacturing processes. This comprehensive guide will equip you with the knowledge you need to select the right sensor for your specific needs, ensuring greater efficiency and reliability in your operations. Whether you’re involved in machinery manufacturing, factory solutions, or industrial automation, this is a must-read to stay ahead of the curve.

PLC vs PC: Key Differences in Industrial Automation

In the realm of industrial automation, the choice between a Programmable Logic Controller (PLC) and a Personal Computer (PC) can significantly impact operational efficiency and system performance. This article delves into the fundamental differences between these two technologies, helping you make informed decisions for your automation needs.

What is the Most Popular Allen-Bradley PLC?

What is the Most Popular Allen-Bradley PLC? If you’re in the automation industry, you’ve probably heard of Allen-Bradley PLCs. They