Transforming the Future of Industrial Automation: Insights for Automation Engineers

Table of Contents

What are the Different Types of Industrial Automation?

Understanding the types of industrial automation is essential to grasp how automation impacts modern industries. There are several type of automation systems, each suited to different applications:

- Fixed Automation (Hard Automation): This type of automation is characterized by high-volume production and dedicated equipment. Ideal for manufacturing processes that require repetitive tasks, it offers efficiency but lacks flexibility. Once set up, the system is used for a single purpose, making changes difficult.

- Programmable Automation: In this system, production equipment is controlled by a program, allowing for changes in operation. Automation engineers use devices like Programmable Logic Controllers (PLCs) to adjust processes as needed. It’s suitable for batch production where the equipment needs to be reprogrammed for different products.

- Flexible Automation (Soft Automation): Also known as integrated automation systems, this approach allows for easy adaptation to product variations. Machines are controlled by computers, enabling quick changes in processes. This flexibility is crucial in industries where customization is key.

- Industrial Robotics: Robots perform tasks with high precision and consistency. Industrial robots are integral to the automation process, handling everything from assembly to packaging.

Summary Table of Automation Types

| Type of Automation | Characteristics |

|---|---|

| Fixed Automation | High volume, dedicated equipment |

| Programmable Automation | Reprogrammable equipment for different products |

| Flexible Automation | Quick adaptation to product changes |

| Industrial Robotics | Robots performing precise, repeatable tasks |

How Do Automation Engineers Implement Automation Solutions?

The role of an automation engineer is pivotal in bringing automation solutions to life. Implementing industrial automation solutions involves several key steps:

- Assessment of Needs: Understanding the specific requirements of the industrial processes. This involves analyzing current operations to identify areas where automation can be achieved for better efficiency and productivity.

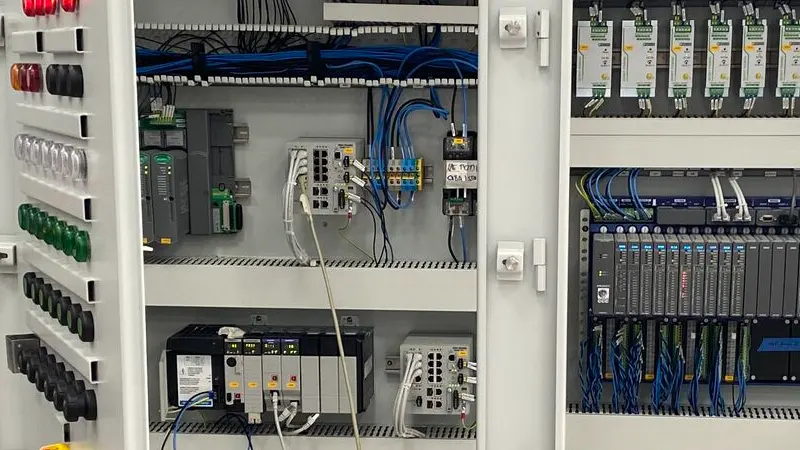

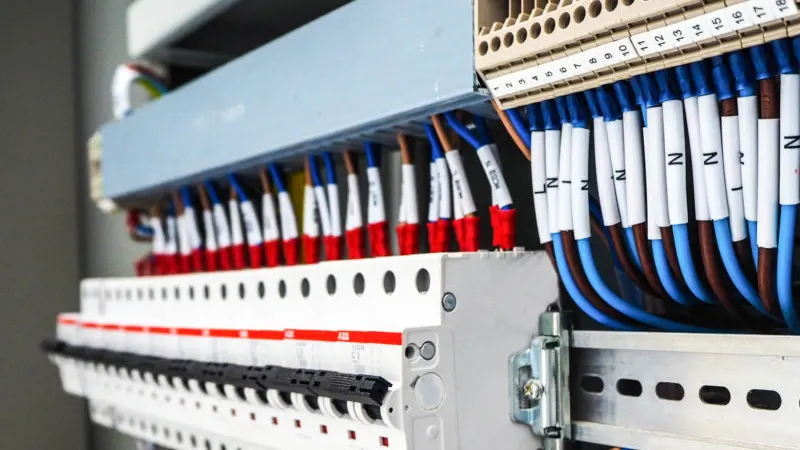

- Design and Development: Creating a blueprint for the automation system, selecting appropriate hardware and software. This might include PLCs, HMIs, sensors, and other devices.

- Programming and Integration: Writing code and integrating various components into a cohesive control system. The goal is to ensure all parts work seamlessly together.

- Testing and Implementation: Rigorous testing to ensure reliability. Implementing industrial automation solutions requires careful planning to minimize disruptions.

- Maintenance and Support: Ongoing support to keep the automation system running smoothly. This includes updates, troubleshooting, and training staff.

What are the Benefits of Industrial Automation?

The benefits of industrial automation are numerous, offering significant advantages over manual operations:

- Increased Productivity: Automation allows for continuous operation without fatigue, increasing output and reducing production time.

- Improved Quality: Automation systems minimize human error, ensuring consistent, high-quality products.

- Enhanced Safety: By handling hazardous tasks, automated systems protect workers from potential dangers.

- Cost Reduction: Though initial investments may be high, the implementation of automation leads to long-term savings through reduced labor costs and increased efficiency.

Additionally, automation offers the ability to quickly adapt to market changes. In the fast-paced industrial automation market, staying competitive requires flexibility and innovation.

What Challenges Exist in Industrial Automation Implementation?

While the widespread adoption of industrial automation brings many benefits, it also presents challenges:

1. Complexity of Industrial Automation

The complexity of industrial automation lies in integrating diverse technologies and systems. Automation engineers must navigate both mechanical and software components, ensuring they work together seamlessly.

2. Cost Considerations

The initial investment for new automation technologies can be substantial. Small and medium-sized enterprises may struggle with the financial burden of upgrading their automation systems.

3. Workforce Impact

Automation can lead to reduced demand for manual labor, impacting employment. However, automation also creates new roles in system management and maintenance.

4. Cybersecurity Risks

With increased connectivity through the Industrial Internet of Things (IIoT), industrial control systems become vulnerable to cyber threats. Protecting these systems is crucial.

5. Technical Challenges

Implementing complex control systems requires specialized knowledge. Training and retaining skilled automation engineers is essential.

What is the Future of Industrial Automation?

The future of industrial automation is dynamic and exciting, with trends pointing towards greater connectivity and intelligence:

- Integration of AI and Machine Learning: Enhancing decision-making and predictive maintenance.

- Expansion of IIoT: Connecting devices to create smarter, more efficient automation systems.

- Edge Computing in Industrial Automation: Processing data closer to the source for faster responses.

- Embracing Industry 4.0: The fourth industrial revolution focuses on automation, data exchange, and smart technologies.

As industrial automation is transforming industries, staying ahead requires embracing these innovations. The future of automation is not just about machines but about creating intelligent systems that enhance every aspect of production.

Frequently Asked Questions

An automation engineer designs, programs, and maintains automation control systems that streamline manufacturing and other industrial processes.

While automation may reduce certain manual roles, it also creates new opportunities in programming, maintenance, and system optimization.

Automation is essential for enhancing efficiency, improving quality, and maintaining competitiveness in the global market.

Challenges include high initial costs, complexity of systems, cybersecurity risks, and the need for specialized skills.

Industry 4.0 integrates digital technologies, allowing for smarter, more connected automation systems that adapt quickly to changes.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- Industrial automation has transformed modern industries, improving efficiency and productivity.

- Understanding different types of industrial automation helps in selecting the right system for specific needs.

- Automation engineers are vital in designing and implementing effective automation solutions.

- Despite challenges, the benefits of automation outweigh the drawbacks, offering significant competitive advantages.

- The future of industrial automation presents exciting opportunities with advancements in AI, IIoT, and Industry 4.0.

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is a Servo and How Does It Work?

One question I often get from clients is: “What exactly is a servo, and how does it work?” Let me break it down for you.

Servos are essential components in modern automation. They provide precise control over motion, which is crucial in many industrial applications.

PLC Interconnectivity: Bridging Data Silos for Smart Manufacturing

Among the surging tide of Industry 4.0, industrial automation systems are expanding significantly intricate, and standalone PLCs are no more sufficient to fulfill developing manufacturing needs.

Reliable and trusted interconnectivity between PLCs has become paramount to damaging information silos and enabling smart production.

Unlock Precision: Mastering Encoders and High-Speed Counters with PLCs

This article dives deep into the world of encoders and high-speed counters (HSCs), explaining how they interface with Programmable Logic Controllers (PLCs) to provide precise control in industrial automation applications. From understanding rotary encoders to configuring HSC modules, we’ll explore how these technologies work together to enhance speed control, position measurement, and overall system efficiency.