CompactLogix vs MicroLogix: Comparing Allen-Bradley PLCs

Table of Contents

What Are CompactLogix and MicroLogix PLCs?

Programmable Logic Controllers (PLCs) are the backbone of industrial automation. CompactLogix and MicroLogix are two prominent PLC lines from Allen-Bradley, designed to meet different automation requirements.

CompactLogix PLCs

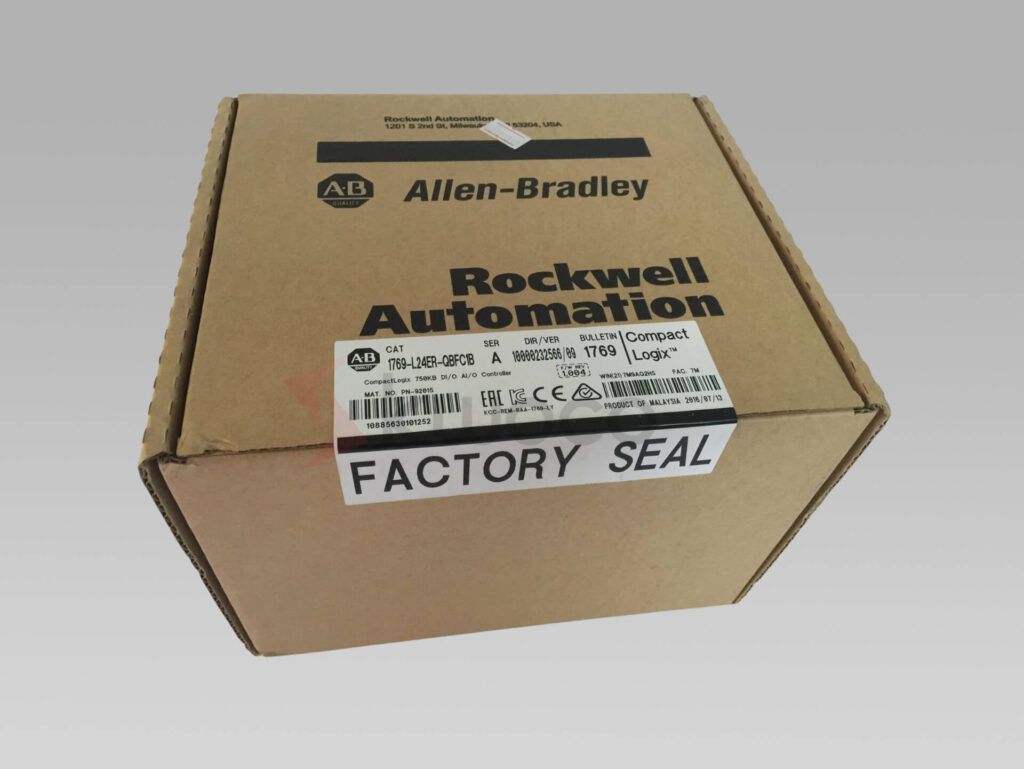

The CompactLogix series offers modular controllers suitable for medium-sized to large applications. These controllers are designed to provide high-performance control and integrated safety features. The CompactLogix controllers support a wide range of communication protocols and offer scalability within the Logix platform.

MicroLogix PLCs

On the other hand, MicroLogix PLCs are compact, built-in controllers ideal for smaller, standalone applications. They offer cost-effective solutions with essential control capabilities. The MicroLogix 1500, for instance, is known for its compact size and ease of use in simple automation tasks.

How Do CompactLogix Controllers Differ from MicroLogix?

Understanding the differences between CompactLogix and MicroLogix controllers is essential for selecting the right PLC for your control system.

Performance and Scalability

- CompactLogix Controllers

- Offer high-performance control suitable for complex applications.

- Scalable within the Logix platform, allowing for system expansion.

- Support motion control and advanced control applications.

- MicroLogix Controllers

- Designed for simple automation tasks.

- Limited scalability compared to CompactLogix.

- Ideal for applications that require basic control capabilities.

Communication and Integration

- CompactLogix

- Supports multiple communication protocols like EtherNet/IP.

- Easily integrates into larger control systems and networks.

- Compatible with Studio 5000 Logix Designer Software for programming.

- MicroLogix

- Limited communication options, primarily using serial communication.

- Suited for standalone applications with minimal integration needs.

- Programmed using RSLogix 500 Software.

Hardware and Modular Design

- CompactLogix

- Modular design allows customization with various I/O modules.

- Power supply and modules can be selected based on application needs.

- Provides redundancy features to minimize downtime.

- MicroLogix

- Built-in I/O with limited expansion options.

- Simplified hardware for quick installation and setup.

- Focuses on cost-effectiveness and simplicity.

Which Allen-Bradley PLC Is Right for Your Automation Needs?

Choosing between CompactLogix and MicroLogix depends on your specific automation requirements.

Consider CompactLogix If:

- You need high-performance and advanced control.

- Your application involves complex processes or motion control.

- Integration with other systems and communication capabilities are crucial.

- Scalability and future expansion are considerations.

Consider MicroLogix If:

- You have a simple automation task with basic control needs.

- Cost-effectiveness is a priority.

- The application is standalone with minimal integration.

- Quick setup and ease of use are desired.

Comparing CompactLogix and MicroLogix in Industrial Automation

In the realm of industrial automation, both CompactLogix and MicroLogix PLCs play significant roles.

CompactLogix in Industrial Automation

- Versatility: Suitable for a wide range of industrial automation applications, from packaging to material handling.

- Integrated Safety: Offers safety features to protect equipment and personnel.

- Performance: Capable of controlling general-purpose motor control applications and more.

MicroLogix in Industrial Automation

- Simplicity: Ideal for simple machines and equipment automation.

- Cost-Effective: Provides essential features without unnecessary complexity.

- Quick Deployment: Reduces programming time and setup efforts.

Exploring the Features of CompactLogix 5380 Controllers

The CompactLogix 5380 controllers represent the latest in the CompactLogix series, offering enhanced features for modern automation needs.

Key Features

- High-Performance Applications: Designed for applications that require high-speed, high-performance control.

- Enhanced Security: Integrated security features protect against unauthorized access.

- Improved Productivity: Faster processing speeds reduce downtime and increase productivity.

- Scalability: Easily scalable for medium to large industrial automation projects.

Communication and Integration

- Supports advanced communication protocols for seamless integration.

- Compatible with the latest Studio 5000 Logix Designer Software.

- Allows for integration with other Allen-Bradley PLCs, including ControlLogix controllers.

Frequently Asked Questions

CompactLogix PLCs are modular and scalable controllers designed for medium to large applications requiring high-performance and advanced control features. MicroLogix PLCs are compact, cost-effective controllers ideal for small, standalone applications with basic control needs.

While it’s possible, integration may be limited due to differences in communication protocols and programming software. CompactLogix uses Studio 5000 Logix Designer Software, whereas MicroLogix uses RSLogix 500 Software.

Yes, CompactLogix controllers support motion control and are capable of handling complex control tasks, making them suitable for applications requiring precise motion and coordination.

Consider factors like application complexity, performance requirements, scalability, communication needs, and budget. For high-performance and scalable solutions, CompactLogix is preferable. For simple, cost-effective control, MicroLogix may be sufficient.

- CompactLogix PLCs are programmed using Studio 5000 Logix Designer Software.

- MicroLogix PLCs are programmed using RSLogix 500 Software.

Yes, certain CompactLogix controllers offer integrated safety features that comply with safety standards, enhancing the protection of equipment and personnel.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

Selecting the right PLC is pivotal for the success of your automation projects. CompactLogix and MicroLogix PLCs from Allen-Bradley cater to different needs within the spectrum of industrial automation.

- CompactLogix PLCs are ideal for complex, high-performance applications requiring scalability and advanced control features.

- MicroLogix PLCs are suitable for simple, standalone applications needing basic control at a lower cost.

- Understanding your application’s requirements will guide you in choosing the appropriate controller.

- Both PLCs have their place in industrial automation applications, and selecting the right one can optimize your system’s efficiency and productivity.

For more insights on PLCs and automation products, you might find these resources helpful:

- Explore our range of Omron PLCs for versatile automation solutions.

- Discover the capabilities of Mitsubishi PLCs in industrial applications.

- Learn about Schneider PLCs for robust control systems.

- Find out how PLC programming can enhance your automation projects.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is the Difference Between PLC, SCADA, and DCS?

In the field of industrial automation, selecting the right control system is crucial. However, the differences between PLC, SCADA, and DCS often cause confusion. As an engineer who has worked at Kwoco for many years, I understand the importance of these terms.

Canada Top 5 Mitsubishi Servo Supplier

As a dedicated engineer at Kwoco, I’ve spent years navigating the industrial automation landscape. My experience with internationally renowned brands like Mitsubishi has equipped me with the knowledge to identify the best suppliers in the market.

Unveiling the Role of Human-Machine Interfaces in Industrial Automation

In the ever-evolving world of industrial automation, the connection between humans and machines has become more crucial than ever. Human-Machine Interfaces (HMIs) serve as the bridge that allows operators to interact seamlessly with complex industrial systems. This article explores the significance of HMIs, their types, and their future in industrial environments. Dive in to discover how HMIs optimize processes, reduce human error, and shape the future of industrial operations.