Understanding the Key Components of a CNC Machine

Table of Contents

What Are the Core Components of a CNC Machine?

- Machine Control Unit (MCU)

- Drive System

- Machine Tool

- Input Device

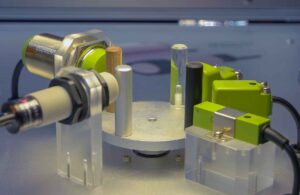

- Feedback System

Machine Control Unit (MCU)

The Machine Control Unit is often referred to as the brain of the CNC machine. It reads the CNC program and converts the programming instructions into electrical signals. These signals control the movement of the machine’s components, coordinating the actions of the drive system and the machine tool.

Drive System

The drive system is responsible for moving the machine components along the desired axes. It typically consists of:

- Servo motors or stepper motors

- Ball screws and lead screws

- Amplifiers or drive controllers

This system ensures that the machine moves accurately, allowing the cutting tool to shape the workpiece precisely. High-quality Mitsubishi servo motors are often used for their reliability.

How Does the Machine Control Unit (MCU) Work?

The MCU processes the programming instructions into the machine, interpreting the commands and controlling the movement of the machine parts. It ensures real-time coordination between the drive system, machine tool, and feedback system.

Input Device and CNC Program Loading

Feedback System and Sensors

Understanding the Drive System in CNC Machines

The drive system plays a crucial role in the CNC machine’s ability to produce high-quality parts. It converts the electrical signals from the MCU into mechanical movements.

Components of the Drive System

- Motors: Usually servo motors or stepper motors that provide precise control.

- Ball Screws and Lead Screws: Convert rotational motion into linear motion.

- Amplifiers: Boost the signals to drive the motors effectively.

The Role of Input Devices in CNC Technology

Input devices are essential for interfacing with the CNC machine. They allow operators to input programming instructions and commands.

Types of Input Devices

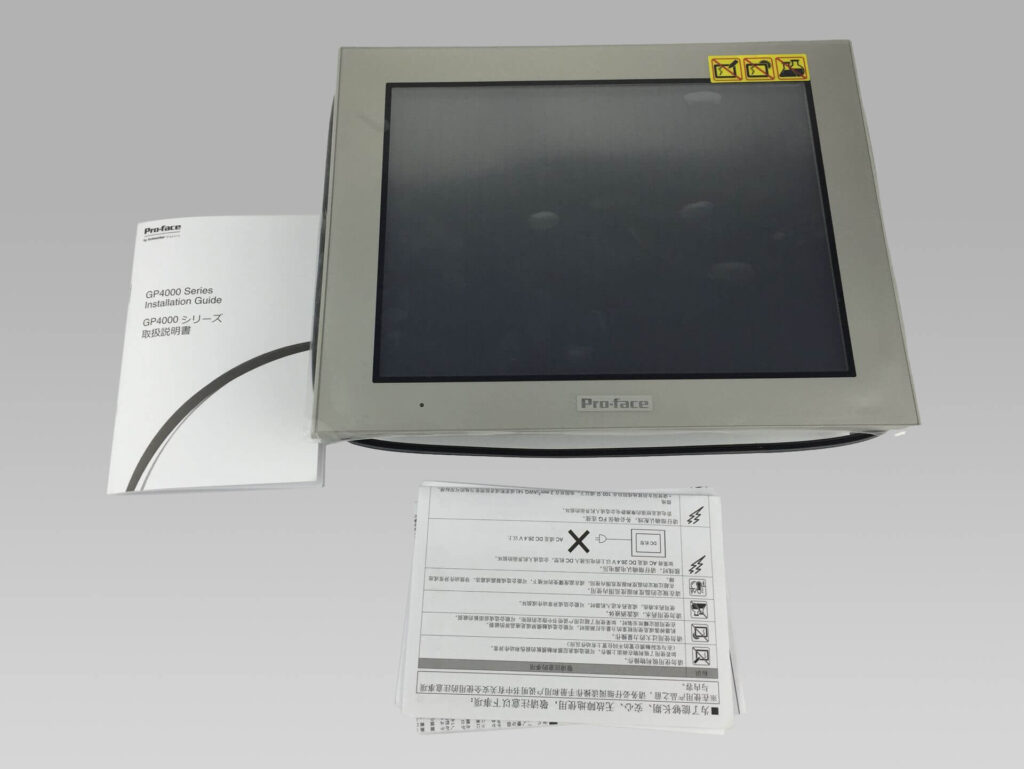

- Keyboards: For typing commands and programs.

- Touchscreens: Modern machines use Proface HMIs for intuitive control.

- Handheld Pendants: Allow for manual control of the machine tool during setup.

Exploring the CNC Block Diagram: A Closer Look

A CNC block diagram illustrates the relationship between the various components of a CNC machine. Understanding this diagram helps in grasping how the CNC system functions as a whole.

Key Elements in the Block Diagram

- Machine Control Unit (MCU)

- Drive System

- Feedback System

- Machine Tool

- Input Device

By exploring the main parts of a CNC, operators and engineers can better understand the components and their functions, leading to more efficient troubleshooting and operation.

The Importance of Each Component in CNC Machines

Every component in a CNC machine contributes to its overall functionality. The synergy between the machine control unit, drive system, input device, and feedback system allows for the precise manufacture of complex components.

Machine Tool and Spindle

The machine tool, including the spindle and cutting tool, physically shapes the workpiece. The spindle holds and rotates the cutting tool, while the drive system moves it along the programmed path.

Control Panel and Display Unit

The control panel, often featuring a Mitsubishi HMI, includes the display unit that shows the machine status and allows operators to monitor and adjust operations.

Auxiliary Systems

- Coolant System: Keeps the cutting tool and workpiece cool during machining.

- Tool Changer: Automatically switches tools when different machining processes are required.

Frequently Asked Questions

The Machine Control Unit (MCU) acts as the brain of the machine, processing the CNC program and controlling the movements of the machine’s components. It ensures that the programming instructions are executed accurately.

The drive system uses servo motors and ball screws to control the movement along the axes precisely. This system ensures that the machine moves the cutting tool accurately to produce the desired shape on the workpiece.

Input devices allow operators to enter programming instructions and interact with the CNC machine. They are essential for setting up the machine and adjusting operations during machining.

Sensors in the feedback system provide real-time data on the machine’s status. They help the MCU make adjustments during machining, ensuring precision and preventing errors.

By understanding the CNC block diagram, operators can see how the components work together. This knowledge aids in troubleshooting, optimizing operations, and improving efficiency.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- CNC machines consist of several key components working in harmony.

- The Machine Control Unit is the central processing unit that directs all operations.

- The drive system and machine tool shape the workpiece with precision.

- Input devices and feedback systems allow for control and monitoring of the machine.

- Understanding each part leads to better operation and maintenance of the CNC machine.

By gaining a comprehensive understanding of the parts of a CNC machine, operators can enhance productivity and produce high-quality parts. This knowledge is fundamental in today’s manufacturing environment, where precision and efficiency are paramount.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What Is an Encoder? Basics of How It Works

Encoders are essential components in today’s automation and motion control systems. They convert motion to an electrical signal that can be read by some type of control device, such as a PLC or a microcontroller. If you’ve ever wondered how machinery precisely detects position and speed, or how robotic arms know where to move, this article is for you. We’ll explore the fundamentals of encoders, their types, and their crucial role in various applications.

Troubleshooting Unresponsive Industrial Touch Screen Panels: A Comprehensive Guide

Is your industrial touch screen panel acting up? An unresponsive touch screen can halt production, create frustration, and cost your business valuable time and money. This article provides a comprehensive guide to troubleshooting common industrial touch screen issues. We’ll explore the reasons behind an unresponsive touch, the steps you can take to solve the problem, and when it’s time to call in the professionals. Learn how to ensure your industrial HMIs remain reliable and contribute to smooth manufacturing operations.

Exploring the Power of Sensors: Types, Uses, and Applications

Sensors are all around us, working quietly behind the scenes to make our lives more convenient, efficient, and safe. From turning on lights when we enter a room to ensuring safety in our vehicles, sensors are integral to modern technology.