NC vs CNC: Understanding the Differences Between NC and CNC Machines

Table of Contents

What is the Difference Between NC and CNC?

In layman’s terms, the main difference between NC and CNC lies in how they are controlled. NC machines rely on a fixed set of instructions punched onto tape or cards, making them less adaptable. In contrast, CNC machines use computer programs, offering greater flexibility and the ability to easily change the program for different tasks. Let’s delve deeper into these differences.

NC stands for Numerical Control, a technology where machines are controlled by a set of instructions in the form of numbers. The first NC machines were developed in the 1940s and 1950s, using punched tape or cards to feed instructions to the machine.

These early NC machines were a significant step towards automation, but they had limitations. For instance, changing the program required manual intervention to alter the punched tape, making the process time-consuming.

CNC, which stands for Computer Numerical Control, evolved from NC technology. CNC machines use an onboard computer to store and execute programs. This means that a skilled operator can easily modify or switch between different programs without physically changing any hardware, like punched cards or tape.

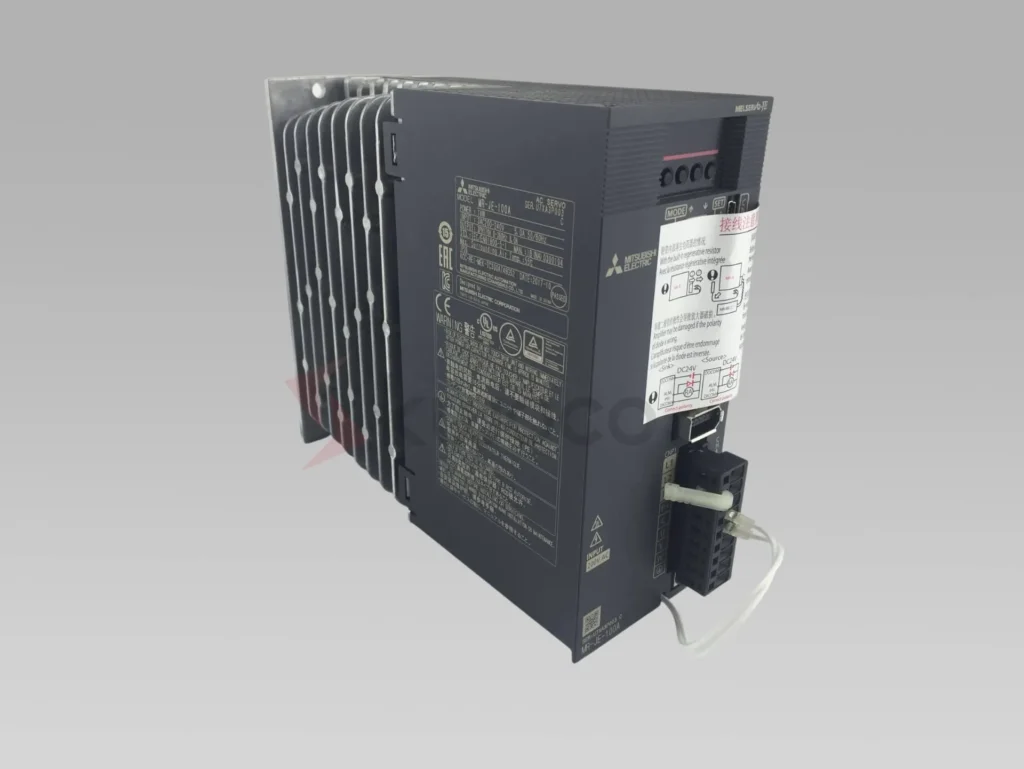

The introduction of Mitsubishi PLC and other advanced controllers has further enhanced CNC machine capabilities, making them highly adaptable to various machining operations.

How Do NC and CNC Machines Function?

Understanding how NC and CNC machines function involves examining their control mechanisms and operational processes. While both aim to automate machine tool operations, their methods differ significantly.

NC machines typically operate in an open-loop system. The machine control unit (MCU) reads instructions from a punched tape or cards and translates them into machine movements. The MCU doesn’t receive feedback from the machine tools, meaning the accuracy relies heavily on the initial setup and calibration.

These machines function based on a predetermined tool path and require manual monitoring to ensure precision. Servo motors are used in the machine tools, but the control is less sophisticated compared to CNC systems.

CNC machines, on the other hand, often utilize a closed-loop system, where the machine controller receives real-time feedback from the machine tools. This allows for automatic adjustments during operation, ensuring higher precision and efficiency.

CNC machines also use servo motors but with a more advanced control system that can handle complex machining tasks. The ability to adapt well to changes and handle intricate designs makes CNC technology superior for modern manufacturing needs.

What are the Types of NC and Their Applications?

NC machines come in various types, each designed for specific tasks. Understanding these types helps appreciate the evolution from NC to CNC.

- Point-to-Point NC Machines: These are the simplest form of NC, where the machine tool moves from one point to another, performing operations at specific locations. Examples include drilling machines and punch presses.

- Contouring NC Machines: These machines can move the cutting tool along a continuous path, making them suitable for milling and lathe operations. They were a significant advancement but still lacked the flexibility of CNC.

Applications of NC machines were primarily in industries requiring repetitive tasks with limited variations. For instance, early NC machines were used to automate the production of aircraft parts, where precision was crucial but the designs were relatively fixed.

How Has CNC Technology Enhanced Manufacturing?

The advent of CNC technology marked a significant leap in manufacturing. CNC machines offer numerous advantages over their NC predecessors.

CNC machines provide greater flexibility and efficiency. They can store multiple programs and easily switch between them, reducing setup time. This capability is particularly beneficial in industries requiring frequent changes in production runs.

For example, a modern CNC machine can quickly adapt from producing one type of Omron sensor to another by simply loading a different program.

Moreover, CNC machines support automatic tool changes, reducing manual intervention. The integration of advanced controllers like Omron PLC further enhances their capabilities, allowing for complex machining operations with high precision.

This makes them suitable for a wide range of industries, including automotive, aerospace, and medical device manufacturing.

What are the Benefits and Drawbacks of Using NC and CNC?

Both NC and CNC technologies have their benefits and drawbacks. Understanding these can help in choosing the right technology for specific applications.

Benefits of NC:

- Simplicity: NC machines are straightforward to operate and maintain.

- Cost-Effective: They are generally cheaper than CNC machines, making them suitable for small-scale operations.

- Reliability: With fewer complex components, NC machines are less prone to breakdowns.

Drawbacks of NC:

- Limited Flexibility: Changing programs is time-consuming and requires manual intervention.

- Lower Precision: Without real-time feedback, the accuracy is less than that of CNC machines.

- Less Adaptable: They are not ideal for tasks requiring frequent changes or complex designs.

Benefits of CNC:

- High Precision: Real-time feedback and advanced control systems ensure high accuracy.

- Flexibility: Programs can be easily changed, allowing for quick adaptation to different tasks.

- Automation: Features like automatic tool changes reduce manual intervention.

Drawbacks of CNC:

- Higher Cost: CNC machines are more expensive to purchase and maintain.

- Complexity: They require skilled operators and programmers.

- Maintenance: The sophisticated components may require specialized maintenance.

Frequently Asked Questions

The primary difference is that NC machines use fixed instructions from punched tape or cards, while CNC machines use computer programs for greater flexibility.

In some cases, yes. Upgrading involves adding a computer control unit and possibly modifying the servo system to support real-time feedback.

ndustries such as automotive, aerospace, and medical device manufacturing benefit significantly from CNC technology due to its precision and flexibility.

Programming can be complex and requires training. However, modern CNC machines often come with user-friendly interfaces and software to simplify the process.

Regular maintenance involves checking and lubricating moving parts, updating software, and ensuring the calibration is accurate. Professional servicing may be required for complex issues.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servo – in stock, ready now!

Conclusion

- NC machines use fixed instructions, while CNC machines use computer programs.

- CNC technology offers higher precision, flexibility, and automation capabilities.

- NC machines are simpler and more cost-effective for basic operations.

- CNC machines are ideal for complex tasks requiring frequent changes and high accuracy.

- Understanding the differences between NC and CNC can help in selecting the right technology for specific manufacturing needs.

- Proper maintenance and skilled operation are crucial for maximizing the benefits of both NC and CNC machines.

By understanding the distinctions between NC and CNC technologies, businesses can make informed decisions to enhance their manufacturing processes.

Whether opting for the simplicity of NC or the advanced capabilities of CNC, the goal remains the same: to achieve precision, efficiency, and high-quality output.

For further information, you can explore resources like this guide on industrial automation. Additionally, for specialized products, consider checking out Proface HMI for advanced control options.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

What is the Difference Between PLC, SCADA, and DCS?

In the field of industrial automation, selecting the right control system is crucial. However, the differences between PLC, SCADA, and DCS often cause confusion. As an engineer who has worked at Kwoco for many years, I understand the importance of these terms.

Difference Between Omron PLC Models Explained

Difference Between Omron PLC Models Explained Are you struggling to decide which Omron PLC model best fits your project needs?

Canada Top 5 Mitsubishi Servo Supplier

As a dedicated engineer at Kwoco, I’ve spent years navigating the industrial automation landscape. My experience with internationally renowned brands like Mitsubishi has equipped me with the knowledge to identify the best suppliers in the market.