What is The Purpose of a Servo Motor?

Servo motors are used in industrial settings to provide precise control of position, speed, and torque. By converting electrical signals into controlled motion, a servo motor is used to ensure machinery operates with high accuracy and efficiency. This makes them ideal for applications where exact positioning and repeatable movements are essential.

Table of Contents

What is a Servo Motor and How Does It Work?

A servo motor is a specialized electric motor designed for precise motion control. It operates within a servo system that includes the motor, a servo drive (also known as a servo amplifier), and a feedback device like an encoder.

How Does a Servo Motor Operate?

The servo motor receives a control signal that represents the desired output position of the motor shaft. The motor’s internal circuitry compares this command to the current position, adjusting the motor output to achieve the desired movement. This closed-loop system ensures the position of the motor is accurate and consistent.

Key components:

- Servo Motor: Executes the movement.

- Servo Drive: Controls the power sent to the motor.

- Feedback Device: Provides real-time position and speed data.

By continuously adjusting based on feedback, the motor operates with high precision, making it ideal for applications requiring exact movements.

Types of Servo Motors: AC vs. DC Servo Motors

Understanding the types of servo motors is essential when selecting the right motor for your application. The main categories are AC servo motors and DC servo motors.

AC Servo Motors

- Powered by Alternating Current (AC)

- Synchronous motors with high efficiency

- Suitable for high-speed and high-torque applications

- Servo motors’ precision in speed and position control

DC Servo Motors

- Powered by Direct Current (DC)

- Includes DC motors and DC servo motors

- Better for applications requiring quick responsiveness

- Easier to control speed and torque

Both types of servos are used in various industrial applications, with the choice depending on specific performance requirements.

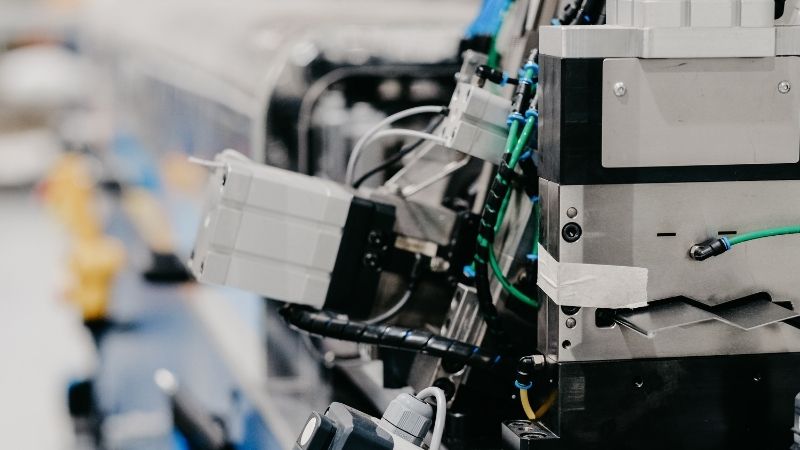

Why Use Servo Motors in Robotics and Automation?

Servo Motors in Robotics

In the field of robotics, servo motors are crucial for controlling the movement of robotic joints and arms. They provide the necessary speed and position control to perform complex tasks with high accuracy.

- Servo motors provide precise motion, enabling robots to handle delicate operations.

- Motors are generally compact, allowing for integration into tight spaces.

- Using a servo motor ensures repeatable and reliable movements.

Servo Motors in Automation

Servo motors are widely used in industrial automation due to their efficiency and precision.

- Servo motor applications include conveyor systems, packaging machines, and CNC equipment.

- Motion control is essential for maintaining product quality and consistency.

- Servo motors excel in environments where motor failure is not an option.

By utilizing servo motors, industries can enhance productivity while maintaining high standards.

Understanding Servo Drives and Motor Control

A servo drive is an integral part of a servo system, responsible for controlling the power supplied to the servo motor.

The Role of Servo Drives

- Acts as a servo amplifier, adjusting current based on control signals.

- Ensures the current to the motor matches the required speed and torque.

- Works in conjunction with feedback devices for precise motor control.

Motor Control Techniques

- Open-loop control: No feedback, not commonly used with servo motors.

- Closed-loop control: Uses feedback to adjust performance, essential for servo systems.

By integrating advanced motor control methods, servo motors offer superior performance and reliability.

Choosing the Right Servo Motor: Motor Sizing and Applications

Selecting the right servo motor involves careful consideration of several factors.

Motor Sizing

- Motor sizing ensures that the motor can handle the application’s load without being overworked.

- Factors include torque requirements, speed of the motor, and inertia.

Types of Servos

- Brushless servo motors: Low maintenance, high efficiency.

- Stepper motors: Good for applications requiring precise positioning without feedback.

- Induction motor: Less common in servo applications but can be used with proper controls.

Suitable Applications

- Servo motors are utilized in industries like manufacturing, aerospace, and healthcare.

- They are suitable for applications requiring high precision and repeatability.

- Motors work best when matched correctly with the application’s demands.

Frequently Asked Questions

The primary purpose of a servo motor is to provide precise control of position, speed, and torque in various applications. By utilizing feedback systems, servo motors ensure accurate and repeatable movements.

Unlike regular motors, which may run at constant speed without feedback, servo motors operate within a servo system that monitors and adjusts performance in real-time. This allows for precise motion control.

In robotics, servo motors enable precise movements of robotic components. They provide accurate control over the motor shaft’s position, which is essential for tasks requiring high precision.

Consider the application’s torque and speed requirements, environmental conditions, and compatibility with control systems. Proper motor sizing and understanding the type of servo motor needed are crucial.

Yes, servo motors include models designed for high-power applications. Permanent magnet motors and advanced servo drives can handle increased loads while maintaining precision.

Power your projects with brand-new, original Omron, Mitsubishi, Delta Servos– in stock, ready now!

Conclusion

- Servo motors are essential for precise motion control in industrial settings.

- Understanding the differences between AC servo motors and DC servo motors helps in selecting the right motor.

- Servo drives and motor control systems enhance performance and reliability.

- Proper selection and motor sizing are critical for application success.

- Servo motors in robotics and automation improve efficiency and precision.

Looking for new, original servos for your projects? At Kwoco, we stock the latest servos from top brands like Omron, Mitsubishi, and Delta. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

How to Adjust a Photoelectric Sensor: Expert Guide

Adjusting a photoelectric sensor might seem complex, but with the right approach, it becomes a straightforward task. Today, I want to share my expertise on how to adjust a photoelectric sensor effectively.

What is an Automation System?

Automation systems have become the backbone of modern industries, transforming how we produce goods and services. This article dives into what an automation system is, the different types of automation, and why they are crucial in today’s world. By the end, you’ll understand how automation impacts industries and everyday life, making this a must-read for anyone curious about the future of technology.

VFD vs VSD: Understanding Key Differences in Motor Control

Are you confused about the difference between Variable Frequency Drives (VFDs) and Variable Speed Drives (VSDs)? This comprehensive guide will clarify these essential motor control technologies, helping you make informed decisions for your industrial applications.