Do Touch Screens Work? Understanding the Technology Behind Touch Input

Table of Contents

1. What is a Touch Screen and How Does It Work? Exploring the fundamental principles.

A touch screen is an electronic visual display that a user can control through simple or multi-touch gestures by touching the screen with a special stylus or one or more fingers.

It allows the user to interact directly with what is displayed, rather than using a mouse, touch panel, touchpad, or any other such device. Think of it as a more intuitive way to interact with computers and machinery.

This technology has revolutionized how we interact with electronics, offering a more direct and engaging experience.

Behind the seemingly simple action of touching a screen lies a complex interaction of physics and engineering. At its core, a touch screen relies on a sensor grid to detect the position of the touch event.

The way this detection happens varies depending on the touchscreen technologies used. Whether it’s sensing a change in electrical charge, disrupting infrared beams, or measuring acoustic waves, the ultimate goal is the same: to translate your touch input into a digital signal that the device can understand and act upon.

2. Capacitive Touch Screens: The Modern Standard. How capacitive touch screens work and why they dominate modern mobile devices.

Capacitive touch screens have become ubiquitous, particularly in modern smartphones and tablets. These touchscreens work by using a transparent layer of conductive material, such as indium tin oxide (ITO), on a glass substrate.

This layer creates an electrical field on the surface of the screen. When a finger touches the screen, it disrupts the local electrical field. Sensors at the edge of the screen detect this change in capacitance, allowing the device to pinpoint the exact location of the touch.

Capacitive touch screens offer several advantages that have contributed to their widespread adoption. They are highly responsive and sensitive to touch, requiring only a light touch to activate the touchscreen.

They also support multi-touch screens, which allows the device to detect multiple fingers at the same time, enabling gestures like pinch-to-zoom.

Because they’re generally more durable and offer better image clarity than resistive screens, you see them everywhere, from mobile phones to industrial control panels that demand high precision.

3. Resistive Touch Screens: Simplicity and Durability. Understanding the construction and use cases for resistive touch screens.

Resistive touch screens, while less common in modern mobile devices, still find applications in specific industries, including industrial automation.

A resistive touch screen consists of two layers of electrically conductive material separated by a thin gap. When pressure on the screen is applied, the two layers are pressed together, creating an electrical connection.

The device then detects this connection and determines the position of the touch.

The primary advantage of resistive touch screens is their simplicity and durability. They can be activated with any object, whether it’s a finger, a stylus, or even a gloved hand, making them suitable for environments where users may not be able to use bare fingers.

They are also resistant to dust and water, making them a reliable choice for industrial settings. However, they are typically less sensitive than capacitive screens and mainly used for single touch applications.

Resistive technology might be the perfect choice when high precision is required with a lower budget!

4. Infrared Touch Screens: Touchless Technology. How infrared touch screens use light beams to detect touch input.

Infrared touch screens use an array of infrared beams and light sensors arranged around the perimeter of the display. The infrared touch screens use infrared beams that pass over the touch screen, creating an invisible grid.

When an object, such as a finger or stylus, touches the screen, it blocks one or more of these beams. The sensors detect which beams have been interrupted, allowing the system to determine the x-y touch screen position of the touch.

The key advantage of infrared touch screens is that they don’t require any physical contact with the surface of the screen to detect touch input.

This makes them suitable for applications where hygiene is a concern or where the user needs to wear gloves. They also offer excellent image clarity and can be scaled to very large sizes.

However, they can be more susceptible to false touches from dust or other objects that might disrupt touch recognition.

5. Other Touch Screen Technologies: A look at surface acoustic wave (SAW) and optical imaging technologies.

While capacitive, resistive, and infrared touch screens are the most common, other touchscreen technologies exist. Surface Acoustic Wave (SAW) touch screens use ultrasonic waves that pass over the touch screen.

When a finger touches the screen, it absorbs some of the wave, and the change is detected by sensors.

Optical imaging touch screens use cameras to track the position of objects near the screen. These systems can detect touch input even if the fingers will not be touching the surface of the screen.

Both SAW and optical imaging technologies offer unique advantages in specific applications, but they are generally less prevalent than capacitive, resistive and infrared touch screens.

6. The Role of Touch Screens in Industrial Automation. Discussing the applications in industrial control and manufacturing.

In the realm of industrial automation, touch screens have transformed the way operators interact with machinery and control systems.

The intuitive nature of touch interfaces makes it easier for workers to monitor and adjust processes, leading to increased efficiency and reduced errors. A touch screen is an electronic interface so it’s ideal for integration.

Here are a few ways touch screens are utilized in industrial settings:

- Human Machine Interfaces (HMIs): Touch screens serve as the primary interface for HMIs, allowing operators to monitor and control various aspects of a manufacturing process, such as temperature, pressure, and flow rate. Learn more about HMIs here.

- Programmable Logic Controllers (PLCs): Touch screens can be integrated with PLCs to provide a user-friendly interface for programming and troubleshooting control systems. Check out our selection of PLCs.

- Supervisory Control and Data Acquisition (SCADA) Systems: Touch screens offer a visual representation of the entire industrial process, enabling operators to monitor and control equipment from a central location.

By providing a clear and interactive way to manage complex systems, touch screens contribute to improved productivity, safety, and overall operational efficiency in industrial environments.

7. Advantages and Disadvantages of Different Types of Touch Screen Technologies. Weighing the pros and cons of each technology for industrial applications.

Choosing the right type of touch screen for your industrial application requires careful consideration of the advantages and disadvantages of each technology.

Here’s a quick comparison:

| Technology | Advantages | Disadvantages |

|---|---|---|

| Capacitive | High sensitivity, multi-touch support, good image clarity, more durable. | Can’t be used with gloves, sensitive to electromagnetic interference. |

| Resistive | Low cost, can be used with any object, resistant to dust and water. | Lower sensitivity, single-touch only, less image clarity. |

| Infrared | Touchless operation, excellent image clarity, scalable to large sizes. | Susceptible to false touches, sensitive to ambient light. |

| Surface Acoustic | High clarity, good light transmission. | Sensitive to surface contaminants, can be damaged by scratches. |

For example, a capacitive touch screen might be ideal for an HMI in a clean, climate-controlled environment where operators need to use multi-touch gestures.

In contrast, a resistive touch screen could be a better choice for a rugged environment where operators need to use gloves or where dust and water are present. Or consider implementing infrared in a sterile environment.

8. Factors to Consider When Choosing a Touch Screen for Industrial Use. Durability, accuracy, and environmental resistance.

When selecting a touch screen for industrial use, consider the following factors:

- Durability: Industrial environments can be harsh, so choose a touch screen that can withstand extreme temperatures, vibration, and impact.

- Accuracy: The touch screen needs to accurately detect touch input, even when the operator is wearing gloves.

- Environmental Resistance: Look for touch screens that are sealed to protect against dust, water, and other contaminants.

- Operating Temperature: Check the specs of the touch screen to make sure it can handle the operating temperature ranges.

- Viewing Angle: Think about the angle the operator will be using the screen from.

- Screen protector: Does the touch screen need a screen protector?

- Tactile feedback: Does it need tactile feedback?

Considering these factors will help you select a touch screen that meets the specific needs of your industrial application and provides years of reliable service.

9. Common Problems with Touch Screens and Their Solutions. Addressing issues like responsiveness, calibration, and damage.

Like any technology, touch screens can experience problems from time to time. Here are some common issues and their solutions:

- Unresponsive Touch Screen: This can be caused by dirt or debris on the surface of the screen, electromagnetic interference, or a faulty sensor. Clean the screen, move away from sources of interference, or replace the touch screen.

- Inaccurate Touch: This can be caused by miscalibration or damage to the touch screen. Recalibrate the screen or replace it if it’s damaged.

- Cracked or Broken Screen: Replace the screen immediately to prevent further damage and ensure safety.

- Slow Response: Ensure the device has enough processing power.

Regular maintenance and prompt repairs can help keep your touch screens operating smoothly and efficiently.

10. Future Trends in Touch Screen Technology. Exploring emerging trends and innovations.

The field of touch screen technology is constantly evolving. Here are a few emerging trends to watch:

- Haptic Feedback: This technology provides tactile feedback to the user, making the touch experience more immersive and intuitive.

- Flexible and Foldable Touch Screens: These screens can be bent or folded without damage, opening up new possibilities for device design.

- 3D Touch: This technology can detect the amount of pressure applied to the screen, allowing for more nuanced interactions.

- Advanced Materials: Innovations in materials science are leading to more durable, transparent, and responsive touch screens.

These trends promise to further enhance the capabilities and applications of touch screens in the years to come. This is why it’s vital to partner with an industry leader to stay at the cutting edge of manufacturing.

11. How Kwoco Can Help You Implement Touch Screen Technology. Showcasing our expertise and product offerings.

As a supplier of industrial automation and industrial control products, Kwoco is uniquely positioned to help your machinery and equipment factory or factory solution company implement touch screen technology effectively.

We offer a wide range of touch screen solutions, including HMIs, PLCs, and SCADA systems, all designed to withstand the rigors of industrial environments.

Our team of experts can work with you to assess your specific needs and recommend the best touch screen technology for your application.

Here are some additional ways we can help you get the most out of your touch screen investments:

- Customized Solutions: We can tailor our products and services to meet your specific requirements, ensuring a perfect fit for your application.

- Technical Support: Our team of experts is available to answer your questions and provide technical assistance whenever you need it.

- Integration Services: We can help you integrate touch screens with your existing control systems, ensuring seamless operation and data exchange.

Ready to upgrade your industrial automation systems with advanced touch screen technology? Contact us today to learn more about our products and services.

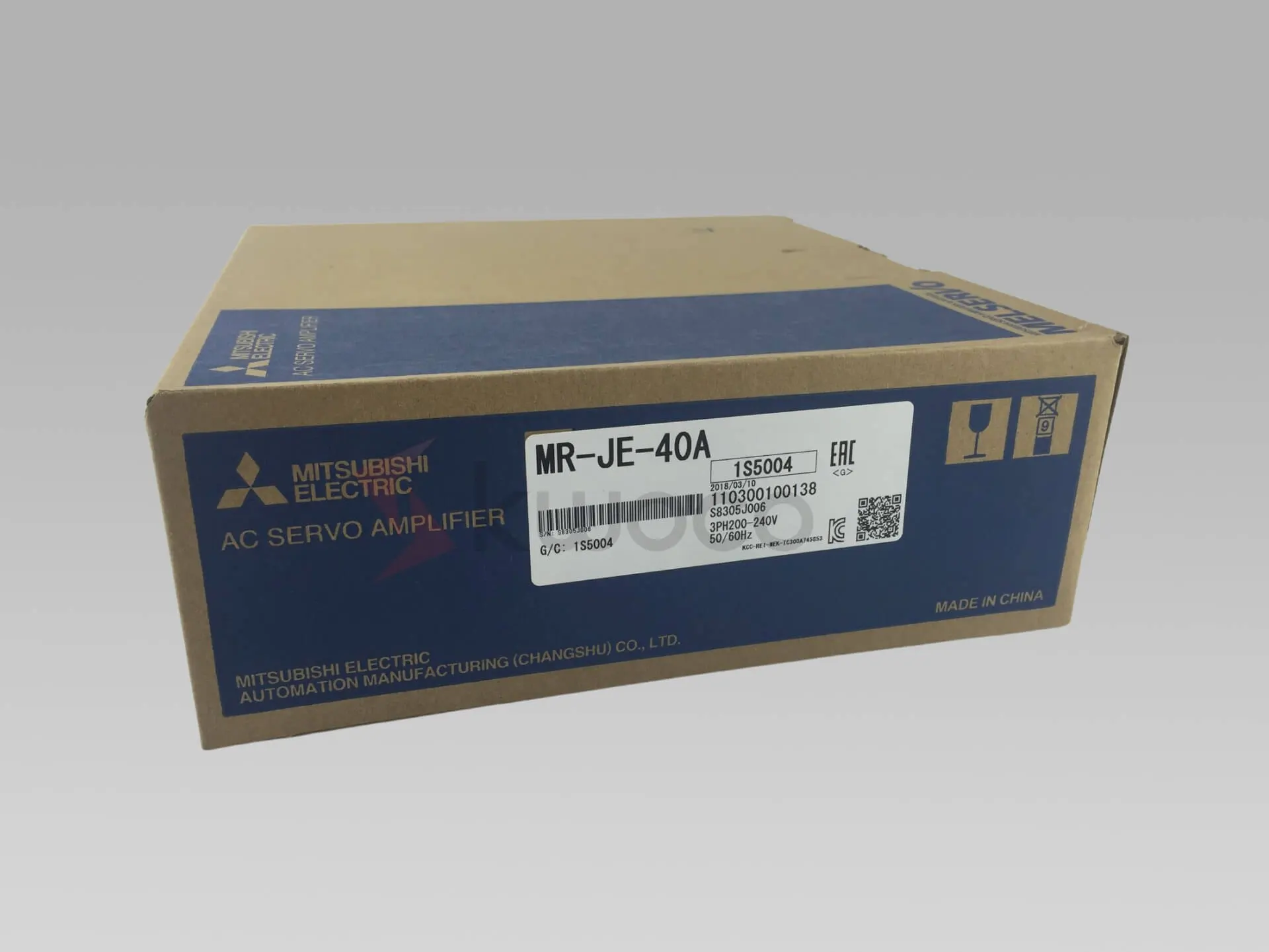

We’re here to help you improve your efficiency, productivity, and safety. Take a look at our offerings for Omron PLC, Mitsubishi HMI, and Schneider PLC. We’ll help you transform your factory floor into a modern marvel.

Frequently Asked Questions

Capacitive touch screens use an electrical field to detect touch, while resistive touch screens use pressure to create an electrical connection. Capacitive screens are more sensitive and support multi-touch, while resistive screens are more durable and can be used with any object.

Resistive and infrared touch screens can be used with gloves. Capacitive touch screens typically require a bare finger or a special stylus.

Use a soft, lint-free cloth to gently wipe the screen. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface.

First, clean the screen to remove any dirt or debris. If that doesn’t work, try recalibrating the screen. If the problem persists, there may be a hardware issue that requires repair or replacement.

Yes, but it’s important to choose a touch screen that is specifically designed for industrial use. These screens are typically more rugged and resistant to dust, water, and extreme temperatures.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider HMI – in stock, ready now!

Conclusion

- Touch screens have revolutionized how we interact with technology, offering intuitive and engaging interfaces.

- Capacitive touch screens are the modern standard, known for their sensitivity and multi-touch capabilities.

- Resistive touch screens offer simplicity and durability, making them suitable for industrial environments.

- Infrared touch screens provide touchless operation, ideal for applications where hygiene is a concern.

- Choosing the right type of touch screen for your industrial application requires careful consideration of durability, accuracy, and environmental resistance.

- Kwoco can help you implement touch screen technology effectively, offering a wide range of solutions and expert support.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Electrical Relay: Understanding the Different Types of Relays

This article delves into the fascinating world of relays, exploring their various types, functionalities, and applications. As a leading provider in the industrial automation sector, we understand the critical role relays play in machinery and equipment factories, manufacturing plants, and factory solution companies. This comprehensive guide will not only enhance your understanding of relays but also demonstrate why our expertise in industrial control products makes us the ideal partner for your automation needs.

Understanding Human-Machine Interfaces (HMIs) in Industrial Automation

Understanding Human-Machine Interfaces (HMIs) in Industrial Automation In the rapidly evolving world of industrial automation, Human-Machine Interfaces (HMIs) play a

Lenze Drive Error Codes: How to Connect, Operate, and Fix Common Faults

This article provides a comprehensive guide to understanding, troubleshooting, and resolving common fault codes in Lenze drives. If you’re working in industrial automation, particularly with machinery and equipment factories or manufacturing plants, this guide will be an invaluable resource. We delve into the intricacies of Lenze drive error codes, offering practical solutions and expert insights to enhance your operational efficiency and minimize downtime. Understanding these error codes is essential for maintaining the reliability and longevity of your equipment.