Siemens Drive Fault Code: A Comprehensive Guide to Troubleshooting and Resolution

Table of Contents

Detailed Explanation of Each Subheader

1. What is a Siemens Drive Fault Code?

A Siemens drive fault code is a diagnostic message displayed on the drive’s HMI or through a connected system, indicating a specific malfunction or issue within the drive system. These codes are essential for identifying problems quickly.

They are generated when the drive’s internal diagnostics detect an abnormal condition, such as overcurrent, overvoltage, or a sensor fault. Siemens drives, including the SINAMICS series, utilize a comprehensive system of fault codes to ensure precise diagnostics.

As an industrial automation expert, I’ve seen firsthand how these codes can significantly reduce downtime. For example, a fault code might indicate that a motor is overheating due to inadequate motor cooling. Recognizing this early can prevent more severe damage.

In fact, it’s just like a person’s body temperature. When we have a fever, our body temperature will rise. Similarly, when a machine breaks down, it will promptly sound an alarm, and these fault information will help us quickly locate the cause of the problem.

Our industrial automation solutions are designed to integrate seamlessly with Siemens drives, providing real-time monitoring and diagnostics. The picture below shows the integration of our products.

2. Why Are Siemens Drive Fault Codes Important for Industrial Automation?

Siemens drive fault codes play a crucial role in maintaining the efficiency and reliability of industrial automation systems. Understanding and correctly interpreting these codes can help you quickly identify and rectify issues, minimizing downtime and preventing costly repairs.

Our experience in process instrumentation has shown that timely diagnostics are critical. As a manufacturer of industrial control products, we emphasize the importance of accurate fault detection in our training programs.

Siemens drive fault codes are vital for:

- Rapid Issue Identification: Quickly pinpointing the cause of operational issues.

- Preventive Maintenance: Identifying potential problems before they escalate into major failures.

- Optimizing Performance: Ensuring that motors and drives operate within their specified parameters.

For instance, a fault code signaling an overload condition can alert operators to adjust the load or investigate the motor circuit, thus preventing damage and downtime.

Our PLC and automation systems are designed to work seamlessly with Siemens drives, enhancing the overall efficiency of your operations. I want to emphasize that no matter how good a machine is, it will inevitably fail, so being able to identify the problem in time is the most important thing.

3. How Do I Access the Fault Code on a Siemens Drive?

Accessing the fault code on a Siemens drive typically involves navigating through the drive’s human-machine interface (HMI) or using diagnostic software like Starter or SIEPortal. The manual for your specific drive model will provide detailed instructions on how to access these codes. You can also utilize Siemens online support for additional guidance.

Here are the general steps to access fault codes:

- Using the HMI: Navigate through the menu to find the “Diagnostics” or “Fault History” section.

- Using Software: Connect your computer to the drive and use Siemens diagnostic software to read the fault codes.

As an expert in industrial automation, I recommend familiarizing yourself with both methods. This ensures you can quickly retrieve fault information regardless of the situation.

If you need help, our MI digital solution integrates with Siemens drives to provide advanced diagnostic capabilities, making it easier to monitor and troubleshoot your systems.

4. What Are Some Common Siemens Drive Fault Codes?

Several fault codes frequently appear in Siemens drives. Here are some common Siemens drive fault codes and their potential causes:

| Fault Code | Description | Possible Causes |

|---|---|---|

| F01000 | Internal software error | Software glitch, parameter issue |

| F07011 | Motor overtemperature | Inadequate cooling, motor overload |

| F07900 | Motor stalled | Excessive load, mechanical blockage |

| F30001 | Power unit overcurrent | Short circuit, ground fault, incorrectly set parameters |

| F30004 | Converter overtemperature | Improper ventilation, high ambient temperature |

Understanding these common Siemens drive fault codes helps in preparing for potential issues and streamlining the troubleshooting process. For instance, fault F07900 indicates motor may be stalled.

Our industrial control products are designed to help engineers diagnose and resolve such issues efficiently, ensuring continuous operation. The same goes for F07011, which means the motor is running too hot.

5. How Can I Troubleshoot a Siemens Drive Based on the Fault Code?

Troubleshooting a Siemens drive involves identifying the fault code, understanding its meaning, and taking appropriate corrective actions. Each code indicates a specific issue, and the Siemens drive manual provides detailed troubleshooting steps.

Steps for Troubleshooting:

- Identify the Fault Code: Note the exact fault code displayed.

- Consult the Manual: Refer to the user manual for the meaning of the code.

- Check Possible Causes: Investigate the potential causes listed in the manual.

- Perform Corrective Actions: Implement the recommended solutions, such as checking the motor circuit, power supply, or control settings.

- Reset the Fault: After addressing the issue, reset the fault following the manual’s instructions.

For example, if you encounter fault code F30001 (power unit overcurrent), you should check for a short circuit or ground fault. Our products, such as advanced analyzer systems and valve positioner devices, can help you monitor and maintain the correct parameters to prevent such faults.

6. What Does a Specific Siemens Drive Fault Code Mean?

Each Siemens drive fault code has a specific meaning that indicates a fault or issue within the drive system. Codes are essential for pinpointing problems. To decode the meaning of a specific code, you should consult the Siemens drive manual or use online support.

For instance, if the motor overheats, the drive might display fault code F07011, indicating motor overtemperature.

Here’s a breakdown of a few more codes:

- F01000: Internal software error. This could be due to a software glitch or parameter issue.

- F07900: Motor stalled. This often results from an excessive load or mechanical blockage.

- F30004: Converter overtemperature. Caused by improper ventilation or a high ambient temperature.

Knowing the specific meaning of each fault code allows for precise diagnostics and effective problem-solving. Our industrial control products are designed to complement Siemens drives, providing additional layers of monitoring and control to prevent faults.

7. How Do I Reset a Siemens Drive Fault?

Resetting a Siemens drive fault typically involves addressing the underlying issue and then clearing the fault from the drive’s memory. The manual for your specific drive model will provide detailed instructions on how to reset a fault.

General Steps to Reset a Fault:

- Address the Root Cause: Resolve the issue that triggered the fault, such as fixing a short circuit or improving motor cooling.

- Power Cycle the Drive: Turn off the power to the drive, wait a few seconds, and then turn it back on.

- Use the HMI or Software: Navigate through the HMI menu or use diagnostic software to clear the fault history.

For example, after resolving an overload condition that caused fault F07900, you would typically power cycle the drive and clear the fault through the HMI. Our industrial automation solutions, including PLC systems and HMI devices, are designed to simplify these processes, ensuring quick recovery from faults.

8. When Should I Seek Professional Help for Siemens Drive Faults?

While many Siemens drive fault codes can be resolved through basic troubleshooting, there are situations where professional help is advisable. Consider seeking assistance if:

- The fault persists after following the manual’s troubleshooting steps.

- The fault code indicates a complex issue, such as an internal software error.

- You are unsure about the correct troubleshooting procedure.

- The drive is part of a critical system where downtime must be minimized.

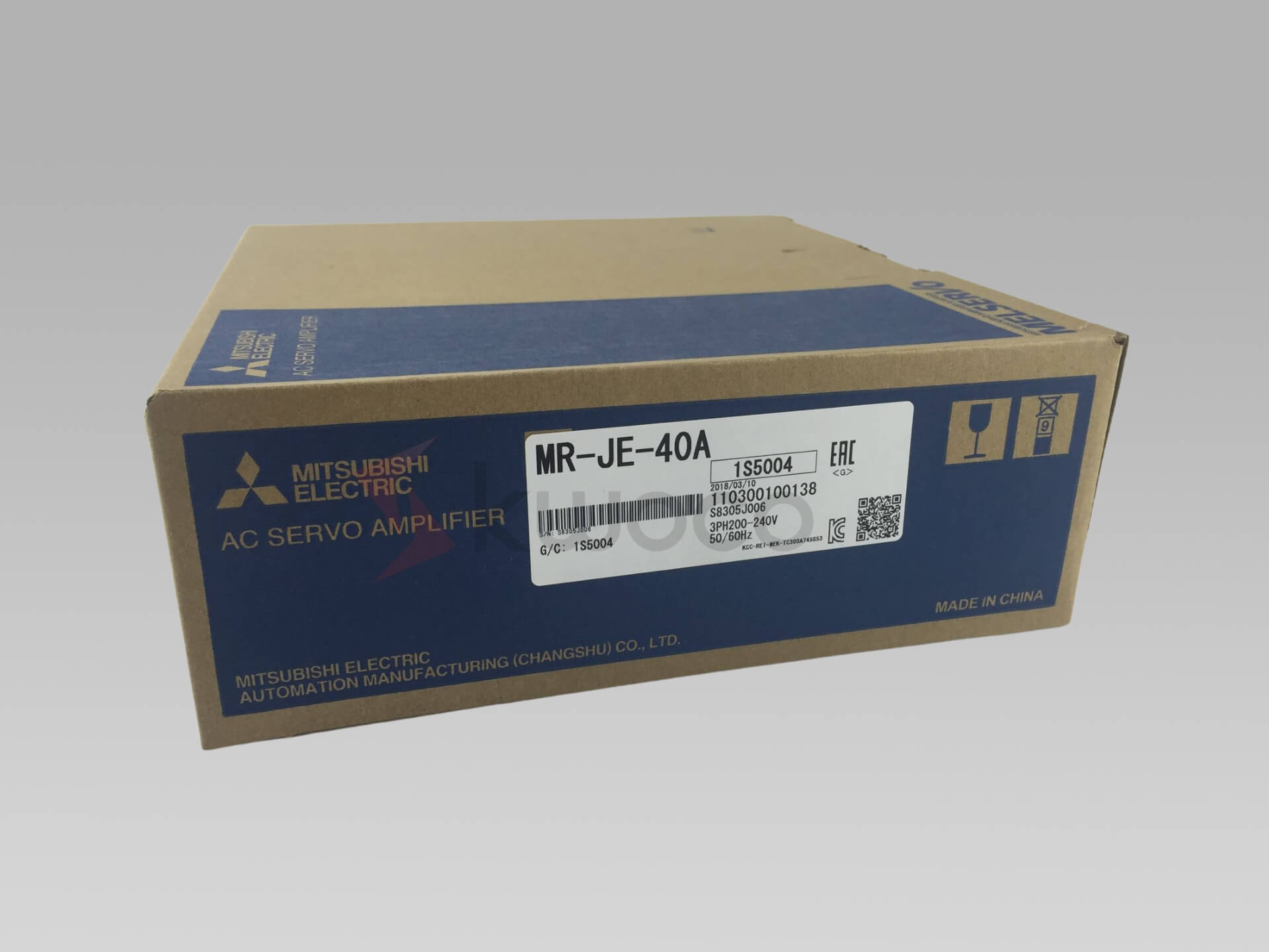

In such cases, contacting Siemens industry support or a qualified engineer can provide the expertise needed to resolve the issue efficiently. As a provider of industrial control products, we also offer expert support and services to help you address complex drive faults and maintain optimal system performance. In addition, we provide customers with a variety of industrial automation spare parts, including Mitsubishi PLC, Mitsubishi Servo, Mitsubishi Inverter, etc.

9. How Can I Prevent Siemens Drive Faults?

Preventing Siemens drive faults involves proper installation, regular maintenance, and monitoring of the drive system. Here are some preventive measures:

- Proper Installation: Ensure the drive is installed according to Siemens guidelines, with proper wiring and grounding.

- Regular Maintenance: Perform routine checks and maintenance, such as cleaning ventilation filters and inspecting connections.

- Monitor Parameters: Regularly monitor critical parameters like motor current, voltage, and temperature.

- Use Quality Components: Utilize high-quality motors, cables, and other components that are compatible with Siemens drives.

- Optimize Control Settings: Ensure control settings, including PID controller parameters, are correctly configured and optimized.

Implementing these preventive measures can significantly reduce the likelihood of faults and extend the lifespan of your Siemens drives. Our industrial control products, including advanced monitoring and diagnostic tools, are designed to support these preventive measures, helping you maintain a reliable and efficient automation system. In addition, we also provide related products such as Omron PLC, Omron HMI, Omron Inverter, etc.

10. Where Can I Find More Information and Support for Siemens Drives?

Siemens provides extensive resources and support for their drives, including detailed manuals, online documentation, and technical support services. Here are some key resources:

- Siemens Industry Online Support: Access product manuals, FAQs, and technical articles.

- Siemens Technical Support: Contact Siemens directly for expert assistance with drive faults and other technical issues.

- Siemens Training Courses: Participate in training programs to enhance your knowledge of Siemens drives and automation systems.

- Siemens Community Forums: Engage with other users and experts to share knowledge and solutions.

Utilizing these resources can enhance your understanding of Siemens drives and help you effectively troubleshoot and prevent faults. As a provider of industrial automation solutions, we also offer comprehensive support and resources to complement Siemens offerings, ensuring you have the expertise and tools needed for success. We also provide customers with high-quality industrial automation products such as Schneider PLC, Schneider HMI, Schneider inverter, etc.

Frequently Asked Questions

This fault code indicates motor overtemperature. Check the motor cooling system, reduce the load on the motor, and ensure proper ventilation. If the fault persists, inspect the temperature sensor and consult the manual for further troubleshooting steps.

If a fault code suggests a sensor issue, such as fault F07011, you can test the sensor using a multimeter or replace it with a known good sensor to see if the fault is resolved. Refer to the drive manual for specific testing procedures.

An alarm typically indicates a warning or a less severe issue, while a fault code signifies a more critical problem that may have caused the drive to shut down. Both the alarm and fault information should be used to diagnose and address the issue.

Yes, improper control settings, such as incorrect PID controller parameters or torque limits, can lead to faults. It is essential to configure the drive according to the motor and application requirements, as detailed in the manual.

If you encounter a fault code not listed in the manual, it is advisable to contact Siemens industry support for assistance. They can provide information on the specific fault code and guide you through the troubleshooting process.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- Siemens drive fault codes are crucial for diagnosing and resolving issues in industrial automation systems.

- Understanding common Siemens drive fault codes and their meanings can help minimize downtime and prevent costly repairs.

- Proper troubleshooting involves identifying the fault code, consulting the manual, and performing corrective actions.

- Regular maintenance and monitoring can prevent many drive faults.

- Siemens offers extensive resources and support to help users troubleshoot and maintain their drives.

- In complex cases, seeking professional help from Siemens industry support or a qualified engineer is advisable.

By following the guidelines and insights provided in this article, you can effectively manage Siemens drive faults, ensuring the reliability and efficiency of your industrial automation systems. As an expert in industrial automation and control products, we are committed to providing solutions that enhance your operational capabilities and support your success.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Mastering the Operating Mode of a Timer Switch: A Comprehensive Guide

This article delves into the intricacies of timer switches, offering a comprehensive understanding of their various types, operating modes, and applications. Whether you’re an engineer at a machinery and equipment factory, a manufacturer, or part of a factory solution company, this guide will provide valuable insights into how timer switches can enhance your industrial automation processes.

What is the Function of Omron PLC?

What is the Function of Omron PLC? Are you tired of dealing with unreliable control systems that cause delays and

HMI vs. SCADA: Essential Guide to Industrial Automation

The industrial automation sector has witnessed a revolutionary transformation, with technologies like HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition) leading the way. These systems empower industries to monitor, control, and optimize operations, ensuring improved efficiency and productivity.