Proximity Sensor vs Photoelectric Sensor

Table of Contents

What is a Proximity Sensor?

As a company specializing in industrial automation, we understand that a proximity sensor is a device designed to detect the presence or absence of an object without physical contact. These sensors are essential in various applications, from detecting parts on a conveyor belt to monitoring the position of machine components.

They operate based on different principles, such as electromagnetic fields, light, or sound, depending on the type of proximity sensor. For instance, inductive proximity sensors are ideal for detecting metallic objects, while capacitive proximity sensors can detect a wider range of materials, including non-metals.

Proximity sensors play a critical role in enhancing automation and ensuring operational safety. Their ability to detect objects without touching them reduces wear and tear, minimizes the risk of damage, and increases the overall efficiency of manufacturing processes.

In my experience, these sensors are a cornerstone of modern industrial settings. We help you to choose best option, for example, Omron PLC.

How Do Proximity Sensors Work?

Proximity sensors work by emitting a field or beam and analyzing changes in the return signal. For example, inductive proximity sensors generate an electromagnetic field. When a metallic object enters this field, it induces eddy currents in the object, which in turn affect the sensor’s magnetic field.

The sensor detects this change and triggers an output signal, indicating the presence of an object. Capacitive proximity sensors work similarly, but they are sensitive to changes in capacitance rather than inductance.

Other types, like ultrasonic proximity sensors, use sound waves. They emit high-frequency sound pulses and measure the time it takes for the sound to reflect back after hitting an object.

This method allows them to detect various materials regardless of color or transparency. The principle is straightforward: the closer the object, the shorter the return time of the sound wave.

What are the Different Types of Proximity Sensors?

There are several types of proximity sensors, each suited for different applications. Inductive proximity sensors are widely used to detect metal objects. They are reliable, cost-effective, and robust, making them suitable for harsh industrial environments.

Capacitive proximity sensors can detect both metallic and non-metallic objects, making them versatile for various materials like plastic, glass, and liquids.

Magnetic proximity sensors are designed to detect magnetic fields. They are typically used in conjunction with permanent magnets to sense the position of objects, such as detecting whether a door is open or closed.

Ultrasonic sensors are also considered a type of proximity sensor, utilizing sound waves to measure distances and detect the presence of objects. Their ability to work in challenging conditions makes them a valuable asset in many industries.

What is a Photoelectric Sensor?

A photoelectric sensor is a type of sensor that uses light to detect the presence or absence of an object. These sensors are highly versatile and widely used in industrial automation to detect objects, measure distances, and monitor processes.

They operate by emitting a beam of light and detecting the light that is reflected or interrupted by an object. In my professional journey, I’ve witnessed how these sensors streamline operations and improve efficiency in countless applications.

Photoelectric sensors offer several advantages, including high accuracy, fast response times, and the ability to detect a wide range of materials regardless of their color or surface properties. They are available in various configurations, each designed to suit specific application requirements, making them a preferred choice for many automation tasks.

How Do Photoelectric Sensors Work?

Photoelectric sensors work based on the principle of emitting a light beam and detecting changes in the received light. They consist of a light source (typically an LED) and a receiver that detects the emitted light.

When an object enters the beam of light, it either reflects the light back to the receiver or interrupts the beam, causing a change in the light intensity detected by the receiver.

There are three main operational modes for photoelectric sensors: through-beam, retroreflective, and diffuse. In the through-beam method, the emitter and receiver are positioned opposite each other. The sensor detects an object when it breaks the light beam between the emitter and receiver.

Retroreflective sensors use a reflector to return the light beam to the receiver. An object is detected when it interrupts the beam between the sensor and the reflector. Diffuse sensors detect the light reflected directly from the object. They are ideal for detecting objects with varying colors and surface finishes. You can check our HMI products.

What are the Different Types of Photoelectric Sensors?

Types of photoelectric sensors include through-beam sensors, retroreflective sensors, and diffuse reflective photoelectric sensors. Through-beam sensors offer the longest sensing range and are highly reliable because the light beam only needs to travel in one direction. They are suitable for detecting opaque objects and are less affected by environmental factors like dust and dirt.

Retroreflective sensors also offer a long sensing range but require a reflector. They are ideal for detecting transparent or shiny objects that might not be detected reliably by through-beam sensors. Diffuse sensors are the most versatile as they can detect objects directly without needing a reflector or separate receiver.

They are ideal for detecting objects with varying colors, shapes, and surface finishes. However, their sensing range is typically shorter compared to through-beam and retroreflective sensors.

Proximity Sensor vs Photoelectric Sensor: What’s the Key Difference?

The primary difference between a proximity sensor and a photoelectric sensor lies in their method of detection. Proximity sensors detect the presence or absence of an object based on changes in electromagnetic fields, capacitance, or sound waves, without requiring physical contact.

In contrast, photoelectric sensors use light to detect objects, relying on the reflection or interruption of a light beam to determine the presence of an object.

Proximity sensors are generally more suitable for detecting metallic objects (inductive sensors) or a wide range of materials (capacitive sensors) at shorter distances. Photoelectric sensors, on the other hand, excel at detecting objects over longer distances and can detect a broader range of materials regardless of their material properties.

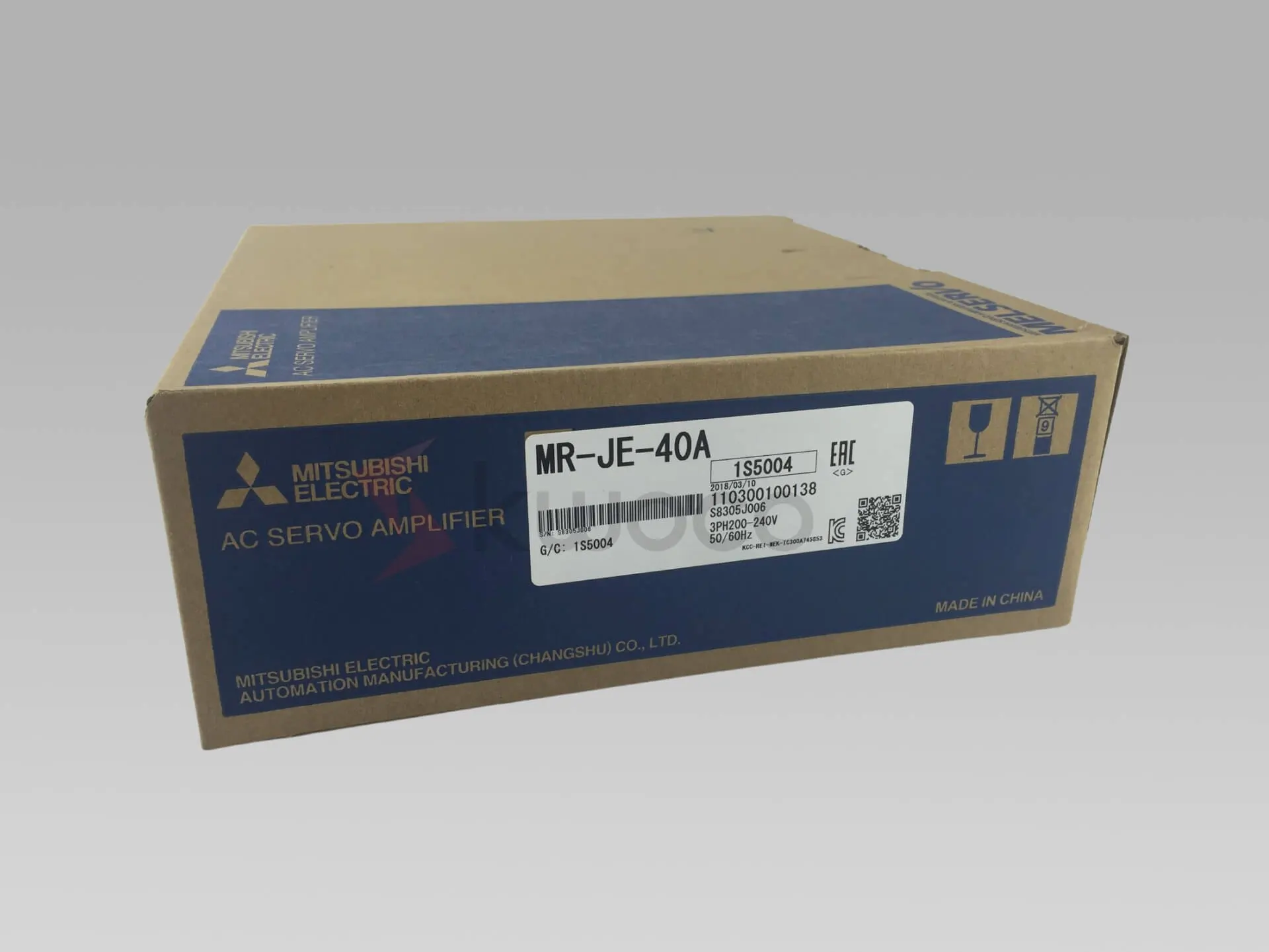

Choosing between the two often depends on the specific application requirements, such as the type of material to be detected, sensing distance, and environmental conditions. We provide many options in this sphere, like Mitsubishi Inverter.

When Should You Choose a Proximity Sensor Over a Photoelectric Sensor?

Choosing a proximity sensor over a photoelectric sensor depends on several factors, including the type of material to be detected, the sensing distance, and the environment. Inductive proximity sensors are the best choice when you need to detect metallic objects within a short range. They are robust, reliable, and unaffected by non-metallic contaminants like dust, oil, or water.

Capacitive proximity sensors are preferred when you need to detect various materials, including non-metals. They are ideal for detecting liquids, powders, and granular materials.

Proximity sensors are also suitable for applications where the sensor needs to be embedded or hidden, as they can detect objects through non-metallic barriers. You can choose also best Servo model.

When is a Photoelectric Sensor the Better Choice?

A photoelectric sensor is the better choice when you need to detect objects over longer distances or when the material properties of the object vary. Photoelectric sensors are highly accurate and can detect a wide range of materials, including transparent, translucent, and opaque objects. They are also less sensitive to the color and surface finish of the object compared to proximity sensors.

Through-beam and retroreflective photoelectric sensors are ideal for applications requiring long sensing ranges and high reliability. Diffuse sensors are suitable for detecting objects with complex shapes or varying colors. Photoelectric sensors are also preferred in applications where non-contact sensing is crucial, such as in food processing or pharmaceutical industries.

How Do You Choose the Right Sensor for Your Application?

Choosing the right sensor—whether a proximity sensor or a photoelectric sensor—depends on understanding the specific needs of your application. Consider the following factors:

- Material Type: Determine the type of material you need to detect. Inductive sensors are best for metals, while capacitive sensors and photoelectric sensors can detect a wider range of materials.

- Sensing Distance: Assess the required sensing distance. Proximity sensors are suitable for short ranges, while photoelectric sensors can cover longer distances.

- Environmental Conditions: Consider the operating environment. Proximity sensors are generally more resistant to harsh conditions, while photoelectric sensors may require protection from dust, dirt, or moisture.

- Response Time: Evaluate the required response time. Photoelectric sensors typically offer faster response times compared to proximity sensors.

- Mounting and Installation: Think about how the sensor will be mounted and installed. Some sensors may require specific mounting arrangements or may be easier to install in certain applications.

| Parameter | Proximity Sensor | Photoelectric Sensor |

|---|---|---|

| Detection Method | Electromagnetic fields, capacitance, sound waves | Light beam |

| Material Compatibility | Primarily metals (inductive), various materials (capacitive) | Wide range of materials, including transparent, translucent, and opaque objects |

| Sensing Distance | Short (typically a few millimeters to a few centimeters) | Short to long (depending on the type: through-beam can detect up to several meters, retroreflective up to a few meters, diffuse) |

| Environmental Tolerance | Generally more tolerant to harsh environments (dust, oil, water) | Can be affected by environmental factors (dust, dirt, moisture); some models are designed for harsh conditions |

| Response Time | Slower compared to photoelectric sensors | Faster response times |

| Cost | Typically lower cost, especially for inductive sensors | Can be more expensive, especially for specialized types |

| Applications | Position sensing, metal detection, object counting in close proximity, level detection (capacitive), presence detection in machinery | Object detection over longer distances, transparent object detection, color detection, presence detection in conveyors |

By carefully considering these factors, you can choose the most appropriate sensor for your application, ensuring optimal performance and reliability. I always recommend consulting with experts to make informed decisions, especially when dealing with complex automation systems.

Frequently Asked Questions

Proximity sensors offer several advantages, including non-contact detection, which reduces wear and tear on both the sensor and the detected object. They are highly reliable and can operate in harsh environments. Inductive proximity sensors are particularly robust and cost-effective for detecting metal objects.

Maintaining photoelectric sensors involves keeping the lens clean and free from dust, dirt, and other contaminants. Regularly check the alignment of the sensor and reflector (for retroreflective types) or the emitter and receiver (for through-beam types). Ensure that the sensor is securely mounted and protected from physical damage.

Yes, capacitive proximity sensors can detect non-metallic objects, including liquids, plastics, glass, and wood. They are ideal for applications where a variety of materials need to be detected.

Some photoelectric sensors are designed for outdoor use and can withstand environmental factors like sunlight, rain, and temperature variations. However, it is essential to choose sensors specifically rated for outdoor applications to ensure reliable performance.

The lifespan of a proximity sensor depends on several factors, including the type of sensor, operating conditions, and maintenance. Generally, proximity sensors are designed for long service life and can last for many years with proper care.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- Proximity sensors and photoelectric sensors are essential components in industrial automation, each offering unique advantages depending on the application.

- Inductive proximity sensors are ideal for detecting metal objects at close range, while capacitive proximity sensors can detect a wide variety of materials.

- Photoelectric sensors excel at detecting objects over longer distances and are highly versatile, capable of detecting transparent, translucent, and opaque objects.

- Choosing between proximity sensors and photoelectric sensors depends on factors such as material type, sensing distance, environmental conditions, and response time.

- Proper maintenance and understanding of sensor principles are crucial for ensuring optimal performance and longevity.

- Consulting with automation experts can help you make informed decisions when selecting and implementing sensors in your applications.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Everything You Need to Know About Contactors and How They Work

This comprehensive guide provides everything you need to know about contactors, including their types, applications, operating principles, and how they compare to relays. Whether you’re an engineer in a machinery and equipment factory, a manufacturer, or part of a factory solution company, understanding contactors is essential for optimizing your industrial automation processes.

CompactLogix vs MicroLogix: Comparing Allen-Bradley PLCs

In the ever-evolving world of industrial automation, choosing the right Programmable Logic Controller (PLC) is crucial for efficient and reliable operations. Allen-Bradley, a brand of Rockwell Automation, offers a wide range of PLCs, including the popular CompactLogix and MicroLogix series. This article delves into a comprehensive hardware comparison of these PLCs, helping you determine which controller best suits your control applications.

Kwoco’s Global Partnership Success Stories

Kwoco’s Global Partnership Success Stories Ever faced the challenge of finding a dependable supplier for industrial control products for an