Why Industrial Ethernet is the Definitive Choice for PLC Automation Networking

Table of Contents

This post offers a thorough analysis of 3 mainstream PLC networking approaches: traditional generic serial communication, closed proprietary fieldbuses, and open, high-speed Industrial Ethernet.

PLC Networking

As industrial automation deepens, the standalone PLC model is no more sufficient to fulfill the demands of facility production procedures.

A stable and efficient interaction network is crucial, whether for data synchronization in between PLCs or for joint work in between PLCs and host systems (like HMI and SCADA), and smart gadgets (such as robotics and variable regularity drives).

A durable networking option is particularly crucial in large-scale tasks with dispersed control points and a requirement for remote operation and maintenance.

Currently, mainstream PLC networking innovations can be split right into three major groups: those based upon generic serial ports, proprietary fieldbuses, and standard Industrial Ethernet. Each strategy has its particular historical context and application scenarios, however the direction of technical development is significantly clear.

1. The Limitations of Generic Serial Communication

Communication based upon generic serial ports like RS-232 or RS-485 was one of the earliest networking approaches. It links multiple PLCs with a host computer system through the PLC’s serial communication component, operating similar to a computer link.

Advantages: It is straightforward to implement and low-priced, making it a cost-effective remedy for point-to-point or small, short-distance control systems.

Disadvantages: The drawbacks of this approach are raw. First, it supplies low speed ; the rate of RS-232 is typically below 115.2 kbps, and while RS-485 is slightly much faster, it is far from sufficient for the huge information transmission demands of contemporary sector. Second, its transmission range is short , with RS-232’s efficient range being only about 15 meters. Lastly, it has weak anti-interference abilities and intricate networking, particularly as the number of nodes boosts. This calls for cumbersome programs and configuration and makes the network prone to electromagnetic interference in industrial settings.

Consequently, generic serial communication is now mostly used for connecting simple auxiliary devices with low real-time requirements.

2. Vendor Barriers: The Era of Proprietary Fieldbus

To get rid of the shortcomings of serial communication, major PLC manufacturers such as Siemens and Rockwell Automation introduced their own exclusive fieldbus procedures, such as PROFIBUS, DeviceNet, and CC-Link.

Advantages: Developed for certain commercial atmospheres, proprietary buses supply high security and real-time determinism , guaranteeing dependable information delivery within split seconds. This makes them highly suitable for closed-loop control applications with rigorous real-time needs, such as high-speed motion control.

Disadvantages: Their greatest weak points are their exclusive nature and high cost . Different vendors’ bus procedures are incompatible, developing “vendor lock-in.” As soon as a specific brand name of PLC is picked, subsequent development gadgets (like drives and I/O components) need to be from the same brand or utilize a suitable method. This not only restricts individual choice but also substantially increases the system’s total cost and upkeep trouble. Furthermore, integrating fieldbuses with enterprise IT networks is complex, hindering the seamless flow of production data to the management level.

3. The Future Standard: The Rise of Industrial Ethernet

With the deep convergence of Information Technology (IT) and Operational Technology (OT), Industrial Ethernet, based on standard Ethernet technology, has emerged. Rep methods include PROFINET, EtherNet/IP, and Modbus TCP. This innovation uses the fully grown TCP/IP method pile to industrial circumstances, creating an open, high-speed, and scalable communication platform.

System Architecture: A typical Industrial Ethernet system is usually divided into three layers: the top layer consists of a monitoring station with industrial PCs or servers; the middle layer is the network framework, made up of industrial switches and twisted-pair cords or optical fiber; the lower layer is the control station, connecting PLCs, sensors, and actuators.

Core Advantages

High Speed and Large Bandwidth: Industrial Ethernet quickly gives data transfer of 100 Mbps, 1 Gbps, or perhaps greater, with the ability of lugging different data kinds, consisting of control signals, diagnostic information, and video clip streams.

Openness and Interoperability: Based on globally accepted Ethernet criteria, devices from various makers can achieve interoperability as long as they follow the exact same Industrial Ethernet procedure, breaking down the barriers of exclusive buses.

Seamless IT/OT Convergence: The use of the TCP/IP protocol allows the factory floor network to integrate natively with the corporate office network (ERP, MES systems), which is fundamental for implementing the Industrial Internet of Things (IIoT) and smart manufacturing.

Flexibility and Scalability: It sustains numerous adaptable network topologies such as star, ring, and line, facilitating network preparation and future growth.

Powerful Diagnostic Capabilities: It provides an abundant collection of network diagnostic devices that can promptly situate fault points, enhancing system maintainability.

Although attaching traditional serial devices to an Ethernet network might originally need procedure converters and include some hardware price, the long-lasting thorough benefits and future compatibility far outweigh this first financial investment.

Core Networking Methods: A Comparative Analysis

To extra plainly highlight the differences amongst the 3 PLC networking methods, the complying with table supplies a comprehensive contrast:

| Feature | Generic Serial (e.g., RS-485) | Proprietary Fieldbus (e.g., PROFIBUS DP) | Industrial Ethernet (e.g., PROFINET/EtherNet/IP) |

|---|---|---|---|

| Communication Speed | Low (Typically < 10 Mbps) | Medium (Up to 12 Mbps) | Very High (100 Mbps / 1 Gbps / Higher) |

| Transmission Distance | Medium (Up to ~1200 meters) | Long (Depends on speed and cable) | Very Long (100m with copper, tens of kilometers with fiber) |

| Openness | Good | Poor (Vendor lock-in) | Excellent (Based on standard Ethernet and TCP/IP) |

| Networking Cost | Low | High | Medium (Hardware costs continue to decrease) |

| IT Integration Capability | Poor, requires gateways | Poor, requires complex gateways | Excellent, seamless integration |

| Real-time Determinism | Poor | Excellent | Excellent (Via technologies like RT/IRT) |

| Topological Flexibility | Limited (Bus) | Limited (Bus) | Excellent (Star, Ring, Line, etc.) |

| Typical Applications | Small-scale, simple device connections | Production line control with high real-time requirements | Plant-wide automation, smart manufacturing, data-intensive applications |

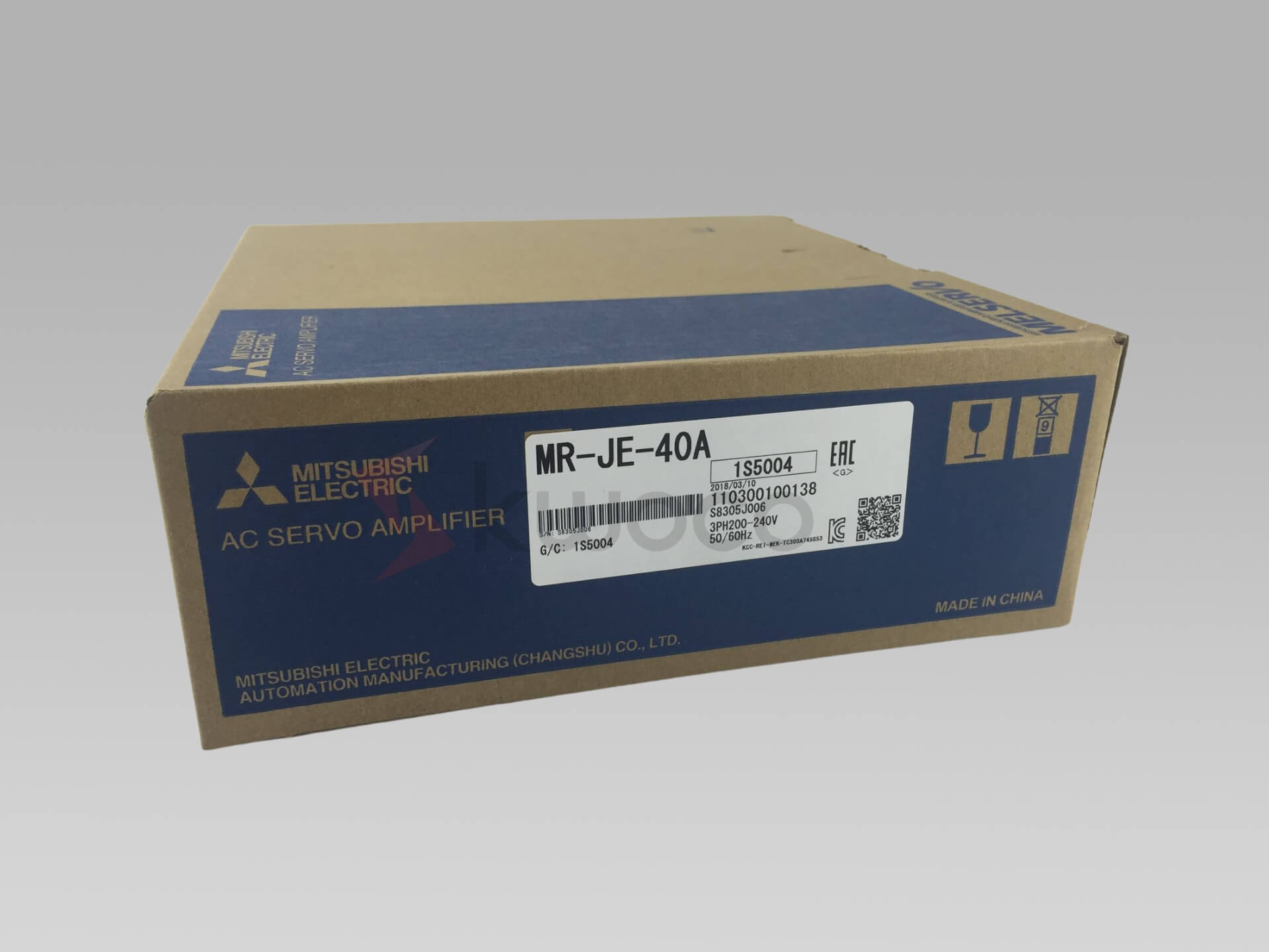

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC– in stock, ready now!

Conclusion

The analysis clearly shows that while generic serial and proprietary fieldbus technologies played important roles in specific historical periods and application contexts, their limitations are increasingly apparent in the new industrial revolution.

Industrial Ethernet, with its exceptional rate, visibility, versatility, and powerful IT assimilation abilities, has come to be the premier option for PLC automation networking. It not only meets today’s complex control demands but also paves the way for enterprises to transition towards the Industrial Internet of Things (IIoT), big data analytics, and cloud platform applications. Choosing Industrial Ethernet indicates choosing a more efficient, scalable, and future-proof automation design.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Understanding Sinking vs. Sourcing in PLC Systems

In programmable logic controllers (PLCs), the terms “sinking” and “sourcing” play a critical role in defining the flow of current in digital input and output modules. While the concept may initially seem technical, it is rooted in basic electrical principles and is key to designing efficient and functional PLC systems.

What are the Three Types of Photoelectric Sensors?

What Are the Three Types of Photoelectric Sensors? When it comes to industrial automation, precision is key. But how can

NPN vs PNP Sensors: Key Differences Explained

Understanding the differences between NPN and PNP sensors is crucial for anyone involved in industrial automation. These sensors are fundamental components in control systems, and knowing how they work can greatly enhance the efficiency and reliability of your operations. This comprehensive guide will demystify NPN and PNP modules and sensors, explain their functionality, and help you decide which type is best suited for your applications.