How to Transfer PLC Program to New PLC

Table of Contents

Intro: Why Your PLC System Urgently Needs a “Brain” Upgrade

In today’s highly automatic manufacturing atmospheres, the PLC functions as the “brain” of the commercial control system. It quietly manages every activity on the assembly line, guaranteeing process accuracy and performance.Nonetheless, several PLC systems that have actually remained in service for a years or even more are gradually transitioning from being valuable possessions to latent liabilities.They might do not have assistance for modern network protocols, possess limited data handling power, face skyrocketing maintenance costs due to terminated spare parts, and, most importantly, stand for an unseen barrier to a firm’s digital transformation trip.Consequently, implementing a PLC innovation and migrating tradition programs to a new-generation system is an important action for business to keep their technological side, enhance operational durability, and embrace Smart Manufacturing.While the procedure is complicated, it can be achieved perfectly with precise preparation and a scientific approach, decreasing manufacturing downtime and unlocking considerable business value.

I. Meticulous Planning and Assessment Before PLC Migration

An effective migration begins with complete preparation. Prior to touching any kind of code or hardware, thorough strategic preparation is vital to prevent project range creep and failing.1. Specify Migration Drivers and Objectives

First, address the core question: “Why are we undertaking this migration?” The driving pressures might include:Efficiency Enhancement: New PLCs feature faster cpus and bigger memory, enabling them to take care of more complex reasoning and decrease check cycle times.Network and Data Integration: Modern systems sustain modern industrial Ethernet procedures like Profinet and EtherNet/IP, helping with seamless combination with MES, ERP, and cloud systems to lay the structure for information analytics and anticipating upkeep.Improved System Reliability and Security: Legacy systems deal with risks from stopped spare parts, whereas brand-new PLC product lines are fully grown and include robust, built-in cybersecurity attributes.Practical Expansion: Gaining support for advanced functionalities such as activity control, equipment vision, and other integrated technologies.2. Conduct an In-depth System Audit and Risk Assessment

Equipment Audit: Meticulously document the design, CPU version, I/O modules, special feature components (e.g., high-speed counters, positioning modules), and network communication components of the existing PLCSoftware Program Audit: Perform a thorough analysis of the existing program. Understand its control logic, program structure (primary regimens, subroutines, interrupts), data frameworks (Data Blocks, or DBs), and the communication procedures and information factors utilized to user interface with higher-level systems like HMI and SCADA.Risk Assessment: Identify possible dangers during the movement, such as program conversion incompatibilities, I/O address mapping errors, communication disruptions, and excessive manufacturing downtime. Establish matching contingency strategies.3. Prepare Essential Tools and Resources

Ensure you have the ideal shows software application for both the old and brand-new PLC platforms. For instance, moving from a Siemens S7-300 to an S7-1500 calls for transitioning from STEP 7 Classic to the extra effective TIA Portal (Totally Integrated Automation Portal). Additionally, prepare programs cords, memory cards, and a dedicated test bench.

II. The Core Phase: PLC Program Conversion and Code Modernization

This is the technical heart of the migration procedure. The challenge lies not just in “equating” the code however additionally in seizing the opportunity to maximize and “improve” the program.1. Program Backup and Upload

Before initiating any type of changes, do a full backup of the existing PLC’s program, data, and equipment setup. This is your project’s last safety net. Next off, utilize the tradition programs software to submit the whole program to your engineering workstation.2. Program Conversion: Direct Conversion vs. Complete Refactoring

There are two primary approaches for program conversion:.Automated/Semi-Automated Conversion: Many leading suppliers provide movement devices. Siemens’ TIA Portal, for example, has a built-in migration function for converting S7-300/ 400 tasks to the S7-1200/ 1500 system. This technique can swiftly transform most of typical guidelines and information blocks but will likely require hand-operated adjustment for certain details instructions, hardware-dependent code (e.g., P_SEND/ P_RECV), or personalized libraries.Manual Refactoring: For tasks with obsolete reasoning, a complicated structure, or missing original documentation, a total rewrite might be the exceptional option. Although it needs more effort, this supplies an exceptional chance to maximize the program framework, add thorough remarks, and adopt a lot more reliable programs methodologies (such as the standard use of Function Blocks, FBs). This substantially improves the program’s readability and lasting maintainability.3. Evaluation of Key Conversion Points

Address and Tag Modernization: The I/O and memory addressing schemes (e.g., M, DB addresses) in new PLCs might vary from those in heritage systems. It is important to transform all hard-coded absolute addresses to adaptable, symbolic attending to (tag-based programs), which is an ideal method in contemporary PLC shows.Handling Instruction Set Discrepancies: The direction collections can vary between different generations of PLCs. As an example, some older communication instructions are superseded by new, more effective instructions on contemporary platforms. You need to carefully speak with the vendor’s movement guidebooks to perform equivalent substitutes.Interaction Configuration: Update tradition serial or MPI/Profibus-DP setups to modern Ethernet-based procedures like Profinet or EtherNet/IP. Re-establish the communication links with gadgets such as HMIs, VFDs, and remote I/O terminals.

III. Comparative Analysis of Mainstream PLC Platform Migration Paths

Selecting the ideal new platform is fundamental to an effective migration. Various brand names offer distinct item functions and migration assistance.| Feature Dimension | Siemens | Rockwell Automation | Mitsubishi Electric |

| Typical Upgrade Path | S7-300/400 → S7-1500 | PLC-5/SLC 500 → ControlLogix/CompactLogix | FX/Q Series → iQ-R/iQ-F Series |

| Core Programming Software | TIA Portal | Studio 5000 Logix Designer | GX Works3 |

| Migration Support Tools | TIA Portal has built-in migration tools supporting direct project conversion and code analysis. | Provides a Translation Tool to assist in converting legacy projects to the new platform format. | GX Works3 includes an import wizard compatible with legacy project files and provides conversion guidance. |

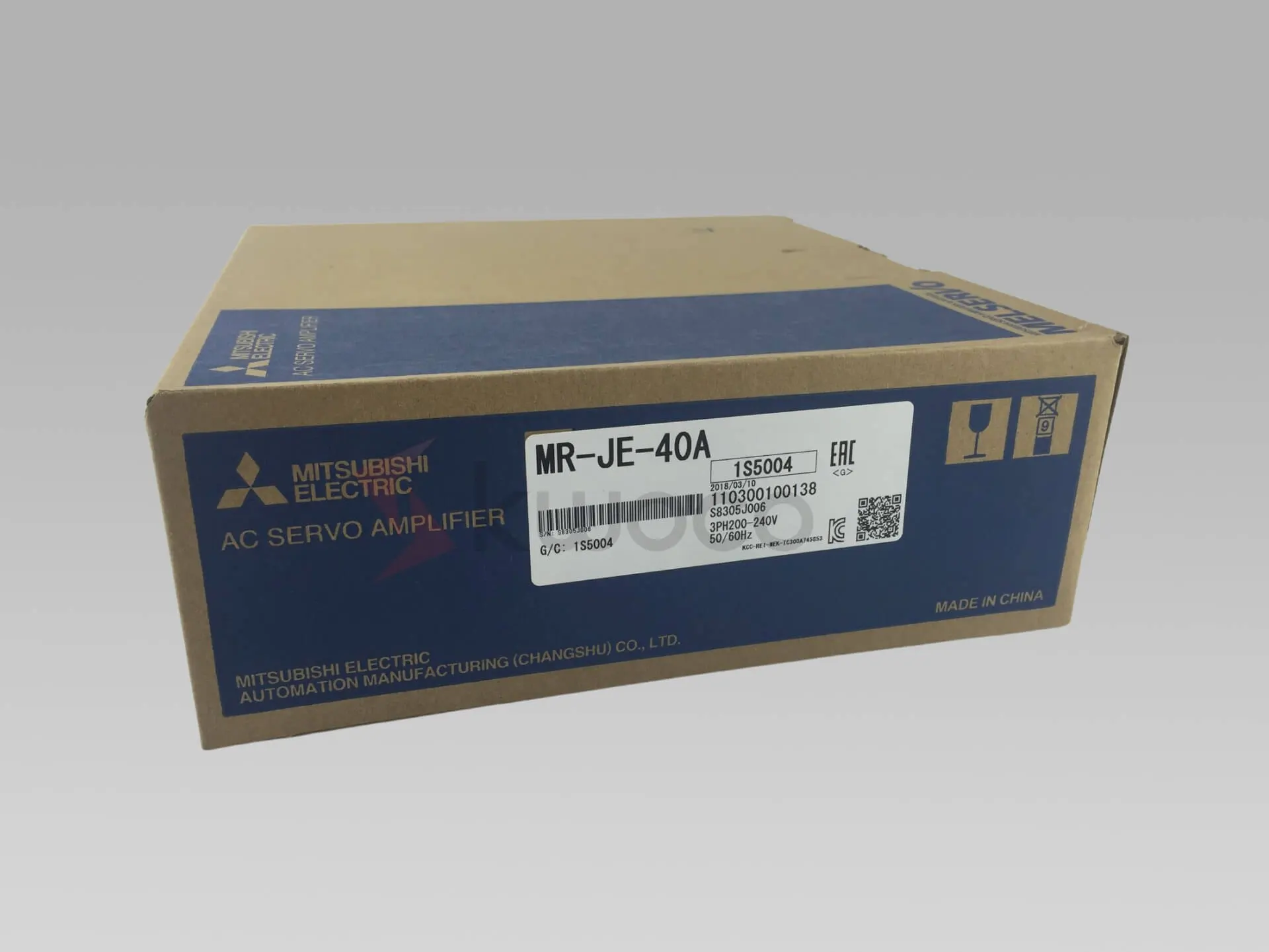

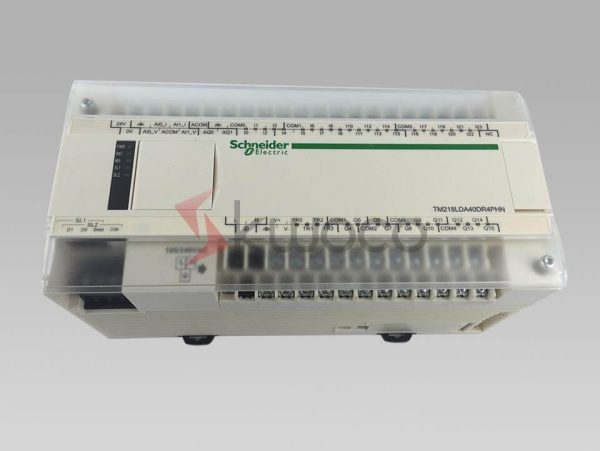

| Key Advantages | Highly integrated platform with strong hardware-software synergy; advanced concepts in symbolic programming and standardization; powerful diagnostic functions. | Flexible tag-based data structure with significant advantages in process control applications; Add-On Instructions (AOIs) facilitate code reusability. | Extensive product line with a high cost-performance ratio; widely used in standalone machines and small-scale systems; strong positioning and motion control capabilities. |

| Potential Challenges | TIA Portal has higher system requirements for the engineering PC; the paradigm shift from classic STEP 7 to TIA Portal involves a learning curve. | Hardware costs can be relatively high; program migration between different families requires attention to detail. | Program compatibility between different series requires careful verification; some special instructions need manual modification. |

IV. Appointing and Integration: Ensuring the New “Brain” Operates Flawlessly

When the program conversion is full, rigorous screening and commissioning are important to assure a smooth production shift.1. Offline Simulation and Virtual Commissioning

Before downloading and install the program to the physical PLC, utilize the shows software’s simulation devices (e.g., PLCSIM Advanced) for comprehensive testing.By linking a virtual HMI and imitating different operating problems and mistake circumstances, you can identify the huge majority of logical mistakes, substantially minimizing on-site appointing time.2. On-site Commissioning

On-site appointing need to be conducted in stages:.I/O Checkout: With the actuators disconnected, test each input signal to validate it is read properly and each result indicate confirm it can be driven appropriately by the program.Specific Machine/Function Testing: Test individual device activities or neighborhood functions to make certain the reasoning is proper.Interlock and System Integration Testing: Integrate the new PLC right into the general system. Conduct communication tests with HMIs, SCADA, robots, and various other PLCs to confirm the sychronisation of the whole production process.Cardiovascular Test and Performance Optimization: Operate the system for an extensive duration under substitute or actual manufacturing conditions. Screen its stability, reaction time, and resource usage (CPU tons, memory) and carry out last optimizations based on the results.

V. Project Closeout: Documents and Training to Solidify Migration Success

A successful job is not only one that runs however additionally one that can be preserved and recognized for several years to come.Update Technical Documentation: Create in-depth paperwork for the brand-new system, including updated electrical schematics, I/O checklists, network geography representations, tag tables, and, most importantly, a printout or PDF of the PLC program with clear, considerable remarks.Personnel Training: Provide organized training for drivers and maintenance engineers. The curriculum needs to cover familiarization with the brand-new PLC hardware, operation of the new programming software application, system start-up and closure procedures, and standard fault medical diagnosis methods.Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

Moving a PLC program to a new system is much more than a simple “copy-and-paste” task. It is an intricate engineering job involving critical preparation, danger management, careful technological implementation, and comprehensive system recognition.

By following the organized actions detailed in this overview– from extensive pre-migration assessment and specific program conversion and innovation to extensive commissioning and combination and complete documentation and training — business can change this technological challenge into a calculated chance to raise their automation degree and enhance their core competitiveness.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

LCD, Digitizer, or Touchscreen Woes? Find the Perfect Industrial Display Solution!

Is your industrial equipment’s display cracked, unresponsive, or simply outdated? Understanding the difference between LCDs, digitizers, and touchscreens is crucial for effective repairs and upgrades. This article dives deep into the world of industrial displays, helping you diagnose problems, choose the right replacement parts, and optimize your machinery for peak performance. We will walk you through what is the digitizer, what is lcd, what is the touchscreen! It’s time to stop guessing and start fixing!

Allen-Bradley PanelView Selection Guide: Choose the Right HMI

Are you looking to select the right Allen-Bradley PanelView for your industrial automation needs? This comprehensive selection guide will walk you through everything you need to know about PanelView Plus 7, PanelView 800, and other graphic terminals in the Allen-Bradley family. Whether you’re upgrading your existing system or starting fresh, this guide will help you make an informed decision.

CNC Router vs Spindle: Which to Use?

This article dives deep into the crucial decision of choosing between a router and a spindle for your CNC machine. Whether you’re a seasoned manufacturer or new to CNC technology, understanding the differences between these two vital components is essential for optimizing your production processes. This comprehensive guide will compare spindles and routers, exploring their capabilities, advantages, and disadvantages to help you make an informed decision that aligns with your manufacturing needs and goals.