Top PLC Manufacturers: The Best Brands in Programmable Logic Controllers

Table of Contents

What Is a PLC and Why Is It Crucial for Industrial Automation?

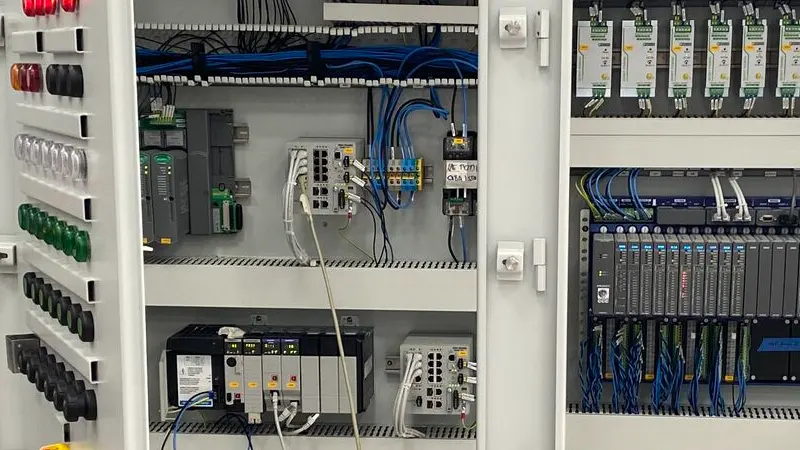

A Programmable Logic Controller (PLC) is a specialized computer used to control machines and processes. In the realm of industrial automation, PLCs are indispensable. But what exactly makes them so vital?

Understanding PLCs:

- Functionality: PLCs are designed to perform a range of tasks, from simple functions like controlling a light switch to complex processes involving multiple inputs and outputs.

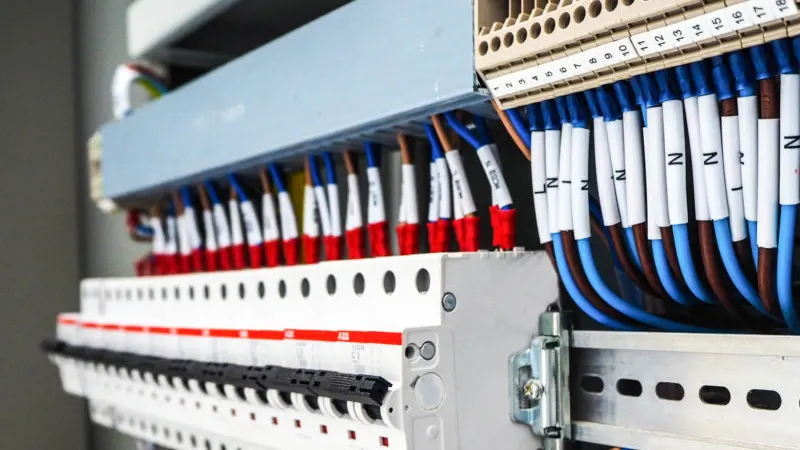

- Reliability: Built to withstand harsh industrial environments, PLCs are ruggedized for temperature extremes, dust, and vibration.

- Flexibility: With a modular design, PLCs can be expanded or modified to meet changing needs.

Importance in Automation:

PLCs are the brains behind automation systems. They enable companies to automate processes, increase efficiency, reduce errors, and improve safety. In essence, PLCs are the backbone of modern industrial control.

Who Are the Top PLC Manufacturers in the Market?

The PLC market is dominated by several key players known for their innovation and reliability. Let’s explore some of the top PLC manufacturers shaping the industry:

Siemens

Siemens is a German multinational conglomerate and a leader in industrial automation products. Their SIMATIC PLC series is renowned for its robustness and versatility.

- Range of PLCs: Offers a large range of PLC products suitable for various applications.

- Innovation: Known for integrating advanced technologies like AI and IoT.

Allen-Bradley (Rockwell Automation)

Allen-Bradley is a brand of Rockwell Automation, an American company specializing in automation solutions.

- PLC Systems: Their ControlLogix and CompactLogix systems are popular in North America.

- Industry Focus: Strong presence in automotive, oil and gas, and manufacturing sectors.

Mitsubishi Electric

Mitsubishi Electric is a global electronics company based in Japan, offering a comprehensive range of PLCs.

- MELSEC PLC: Their MELSEC PLC series is known for performance and reliability.

- Industrial Robots: They also provide industrial robots, enhancing their automation portfolio.

Schneider Electric

- Modicon PLCs: Pioneers in PLC technology with their Modicon range.

- Wide Range of Products: Their offerings include PLCs, HMIs, and more.

Omron

Omron is a Japanese company specializing in industrial automation and control equipment.

- PLC Series: Known for the CJ and CS series PLCs, offering high-speed processing.

- Focus on Innovation: Invests heavily in R&D for automation technologies.

What Sets These PLC Brands Apart from the Rest?

With so many PLC manufacturers in the market, what makes these brands stand out?

Siemens:

- Global Reach: Operates in over 200 countries.

- Comprehensive Solutions: Provides a wide range of industrial automation products.

- Customer Support: Extensive training and support services.

Allen-Bradley:

- Integration with Rockwell Automation: Offers end-to-end automation solutions.

- Industry-Specific Expertise: Tailors products for specific industry needs.

- Reliability: PLCs are known for durability and performance.

Mitsubishi Electric:

- Innovation in Robotics: Combines PLCs with advanced robotic systems.

- Energy Efficiency: Focuses on sustainable automation practices.

- Global Electronics Experience: Leverages expertise from other electronics sectors.

Schneider Electric:

- Energy Management: Combines automation with power management solutions.

- EcoStruxure Platform: An open, interoperable system architecture.

- Customer-Centric Approach: Offers customized solutions.

Omron:

- Sensor Technology: Integrates advanced sensors with PLC systems.

- Flexibility: Offers PLCs in various shapes and sizes for different applications.

- Global Support: Strong presence in Asia Pacific and beyond.

How to Choose the Right PLC Manufacturer for Your Needs?

Selecting the right PLC brand depends on several factors:

- Application Requirements

- Complexity of Control System: For complex systems, choose a manufacturer with high-performance PLCs.

- Environmental Conditions: If operating in harsh environments, select a PLC manufacturer known for ruggedized products.

- Budget Constraints

- Cost of PLCs: Prices vary among brands; consider total cost including software and licensing.

- Long-Term Investment: Consider the longer-lasting benefits of quality PLCs over cheaper alternatives.

- Support and Training

- Technical Support: Ensure the manufacturer offers robust customer service.

- Training Resources: Availability of training can enhance your team’s proficiency.

- Compatibility and Integration

- Existing Systems: Choose PLCs that integrate seamlessly with your current equipment.

- Future Expansion: Consider scalability for future automation needs.

- Industry-Specific Solutions

- Some manufacturers specialize in certain industries. For example:

- Pharmaceuticals: Might require specialized compliance features.

- Automotive: May benefit from brands with expertise in factory automation.

What Are the Latest Trends in PLC Technology?

The world of industrial automation is evolving rapidly. Here are some trends shaping the future:

- IoT and Connectivity

- Smart PLCs: Integration with the Internet of Things (IoT) allows for real-time data exchange.

- Remote Monitoring: Enhanced capabilities for monitoring and controlling processes remotely.

- Advanced Programming

- User-Friendly Software: Development of more intuitive programming environments.

- Open Source Platforms: Increased use of open-source software for flexibility.

- Energy Efficiency

- Sustainable Automation: Focus on reducing energy consumption in control systems.

- Green Technologies: Incorporating environmentally friendly components.

- Artificial Intelligence (AI)

- Predictive Maintenance: AI algorithms detect issues before they cause downtime.

- Optimized Processes: Machine learning improves efficiency over time.

Frequently Asked Questions

A Programmable Logic Controller (PLC) is an industrial computer that monitors inputs and outputs to make logic-based decisions for automated processes. It replaces hard-wired relays and timers with a programmable platform, making control systems more flexible and easier to modify.

Both Siemens and Allen-Bradley have extensive experience in industrial automation. They offer a wide range of PLCs with robust features, excellent customer support, and continuous innovation, making them top choices in the industry.

While it’s possible, integrating PLCs from different manufacturers can be challenging due to compatibility issues. Each PLC brand may use proprietary communication protocols and software. It’s advisable to consult with an automation specialist when attempting such integration.

For harsh environments, consider PLCs that are:

- Ruggedized: Built to withstand temperature extremes, dust, and moisture.

- Certified: Look for certifications relevant to your industry.

- Reliable: Choose PLC manufacturers known for durable products like Omron or Mitsubishi Electric.

- Attend Industry Conferences: Events like the Automation Fair provide insights.

- Subscribe to Trade Journals: Publications focused on industrial automation.

- Manufacturer Training: Enroll in courses offered by PLC manufacturers.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

- PLCs are essential components in industrial automation, controlling various processes and machinery.

- Top PLC manufacturers include Siemens, Allen-Bradley, Mitsubishi Electric, Schneider Electric, and Omron.

- Choosing the right PLC depends on application needs, budget, support, compatibility, and industry focus.

- Emerging trends in PLC technology involve IoT, AI, advanced programming, and energy efficiency.

- Staying informed through education and engagement with manufacturers helps leverage the full potential of PLCs.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Introduction to Programmable Logic Controllers: Your Gateway to Industrial Automation

This article is a comprehensive guide to Programmable Logic Controllers (PLCs), exploring their fundamental role in modern industrial automation. From machinery and equipment factories to manufacturers and solution providers, PLCs are indispensable for streamlining operations and enhancing productivity. This article delves into the intricacies of PLCs, their programming, and their diverse applications.

What is the Function of Omron PLC?

What is the Function of Omron PLC? Are you tired of dealing with unreliable control systems that cause delays and

Common Faults and Troubleshooting of Omron PLC

As a global leader in automation solutions, Omron provides a comprehensive range of Programmable Logic Controllers (PLCs), including the classic CP series, the powerful CJ series, and the future-oriented NX/NJ series. These controllers are widely deployed across diverse industries such as manufacturing, packaging, logistics, and energy. Serving as the “brain” of automated systems, Omron PLCs execute control logic with precision and coordinate the operation of various components.