PLC Gateway Explained: Features, Applications, and Value Analysis

Table of Contents

What is a PLC Gateway?

PLC Programmable Logic Controller is extensively used in industrial automation control, working as a core tool for logic procedures, timing control, and procedure management.

A PLC entrance, on the various other hand, is an interaction and remote monitoring device specifically developed for industrial environments.

It allows PLC-collected data to be posted to cloud systems by means of Ethernet, WiFi, or mobile networks (3G/4G/5G), supporting remote monitoring and intelligent procedure and upkeep.

Unlike standard standalone PLCs, PLC gateways integrate PLC systems deeply with IIoT.

They support multiple commercial communication procedures such as Modbus TCP/RTU, Profinet, and OPC UA, and work with leading cloud systems including Alibaba Cloud, Huawei Cloud, AWS, Microsoft Azure, and Siemens MindSphere.

This enables ventures to promptly develop smart manufacturing facilities, boosting device interconnectivity and functional performance.

Key Features of PLC Gateways

1. Fast Remote Upkeep

No public IP or complicated arrangement is called for– designers can establish a secure channel utilizing only the gadget’s identification number. This makes remote debugging, fault diagnosis, and firmware upgrades quick and effective, significantly enhancing solution action rate.

2. Several Connection Options

PLC gateways support Ethernet, wired/wireless networks (WiFi/3G/4G/ 5G), and PoE (Power over Ethernet). They work with a large range of PLC gadgets using Ethernet and serial ports, making sure adaptable release.

3. Plug-and-Play Cloud Solutions

As opposed to purchasing expensive internal data facilities, enterprises can directly connect to third-party cloud systems for data storage and analysis, decreasing prices.

4. Comprehensive Management Functions

Geared up with industrial-grade administration systems, PLC entrances support asset monitoring, geographical information display, real-time device tracking, and multi-level approval management. This supplies OEMs and end-users with a reputable option for remote procedure and solution delivery.

Application Circumstances of PLC Gateways

PLC portals are commonly made use of throughout industrial automation. Typical application situations consist of:

- Smart Factories : Enabling device connection and remote debugging to enhance manufacturing performance.

- Energy and Power : Sustaining wise grids, water system systems, and central heating boiler control with remote data collection and alarms.

- Municipal and Environmental Protection : Offering remote tracking and data transmission in wastewater therapy and environmental monitoring projects.

- Transportation and Lift Control : Facilitating remote monitoring and fault diagnosis in elevators, building and construction machinery, and packaging equipment.

Contrast: PLC Gateways vs. Traditional PLCs

The table below highlights the functional differences between traditional PLCs and PLC gateways:

| Measurement | Traditional PLC | PLC Gateway |

|---|---|---|

| Information Transmission | Local only, minimal data sharing | Cloud upload and remote transfer |

| Upkeep | On-site debugging, time-consuming | Remote debugging and upgrades, quickly and efficient |

| Price Financial investment | Requires committed web servers | Plug-and-play cloud platforms, minimized expenses |

| Protocol Assistance | Restricted procedures | Supports Modbus, Profinet, OPC UA, etc. |

| Application Scope | Standalone or LAN control | Broad IIoT and clever manufacturing facility applications |

According to a MarketsandMarkets research report, the global IIoT portal market is expected to get to USD 1.4 billion by 2027, with a compound yearly growth price (CAGR) surpassing 12%. This shows that PLC gateways will play a progressively important function in the future of industrial automation.

Why Do Enterprises Requirement PLC Gateways?

- Improved Management Performance : Real-time equipment monitoring and cloud-based analytics provide business much better operational visibility.

- Minimized O&M Costs : Reduces the need for on-site maintenance, specifically beneficial for business with geographically dispersed facilities.

- Enhanced Safety and Stability: Built with industrial-grade enclosures, PLC entrances offer high EMC compatibility, wide temperature level resistance, and lightning protection for reliable efficiency.

- Support for Digital Transformation : Bridges the void between standard automation and smart procedures.

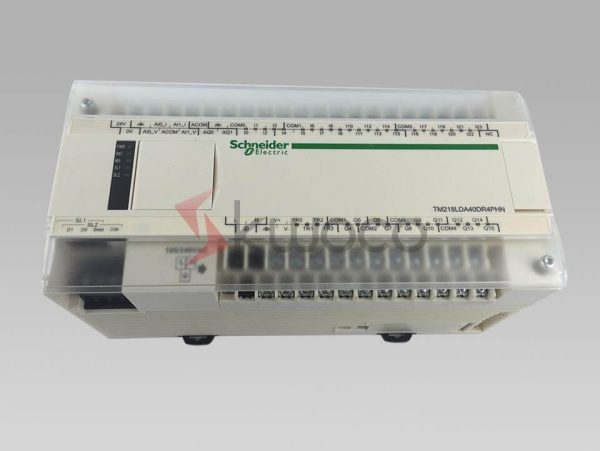

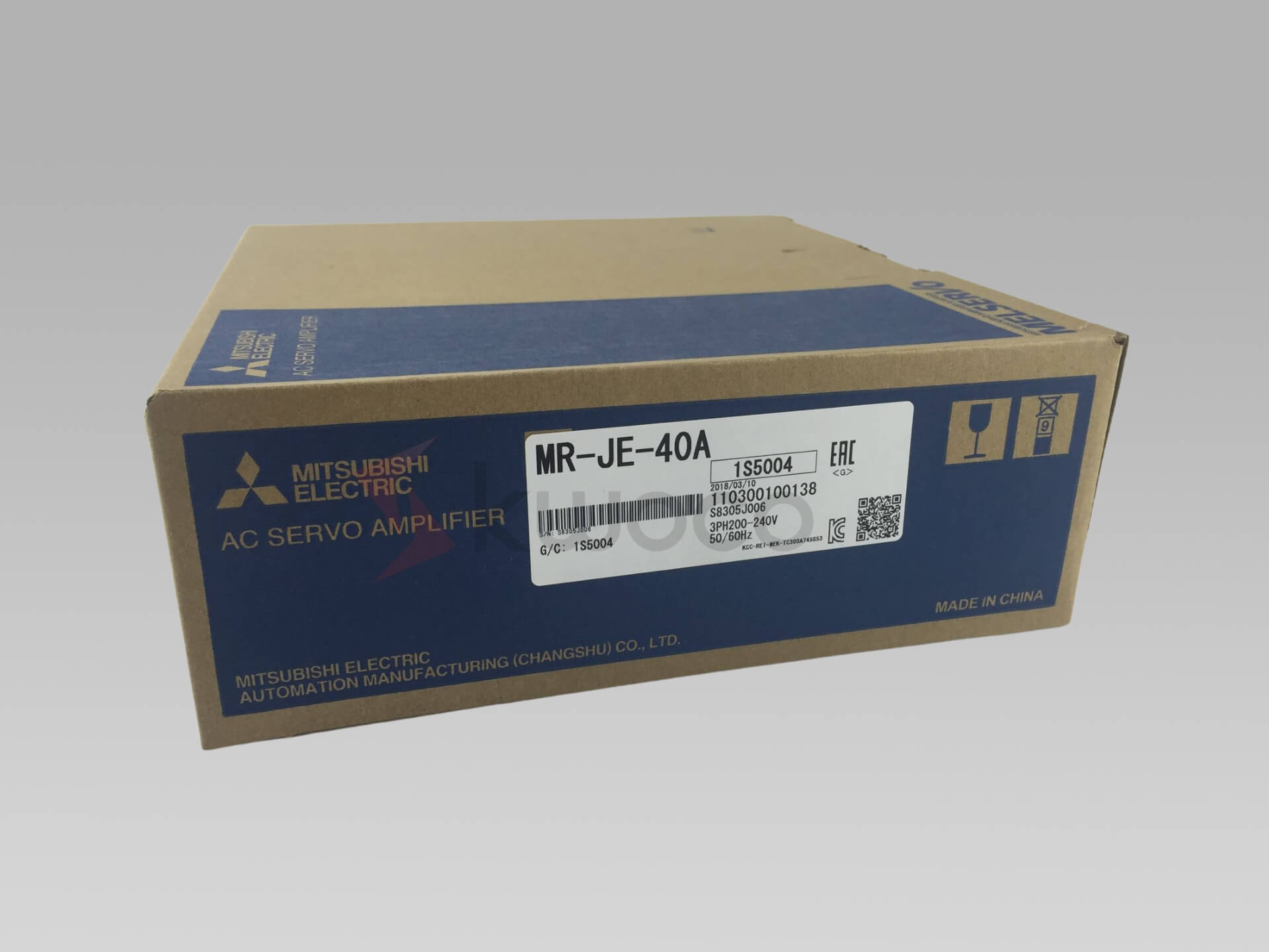

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

As an essential hub of IIoT, the PLC gateway is increasing the advancement of smart manufacturing facilities and commercial electronic transformation. Its flexible networking, powerful remote upkeep abilities, and cost-saving benefits make it a crucial solution for business intending to enhance production performance and smart property monitoring.

Looking in advance, with the continued evolution of cloud computing and 5G technologies, PLC entrances will certainly play an also greater role in industrial automation communities. Enterprises that adopt them early will get a strategic advantage in their digital transformation journey.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Troubleshooting Tips for Omron PLC Systems

Programmable Logic Controllers (PLCs) are the backbone of modern industrial automation, and Omron PLCs are among the most reliable and widely used systems in the industry. However, like any complex piece of equipment, Omron PLC systems can encounter issues that require troubleshooting. Whether you’re a seasoned engineer or a beginner, understanding how to diagnose and resolve common problems can save time, reduce downtime, and improve operational efficiency. In this article, we’ll explore practical troubleshooting tips for Omron PLC systems.

Guide to Common Causes of PLC Failures

PLCs, or Programmable Logic Controllers, are specialized computing devices used to control machinery and processes in industrial settings. These robust systems are designed to withstand harsh environments while providing real-time control and monitoring capabilities.

Canada Top 5 Mitsubishi Servo Supplier

As a dedicated engineer at Kwoco, I’ve spent years navigating the industrial automation landscape. My experience with internationally renowned brands like Mitsubishi has equipped me with the knowledge to identify the best suppliers in the market.