PLC Counter Programming: A Complete Guide for Automation 2024

From basic concepts to advanced implementations, we’ll explore how counters can enhance your control systems and improve manufacturing efficiency.

Table of Contents

What Are PLC Counters and Why Are They Essential in Automation?

In the world of programmable logic controllers, counters are fundamental building blocks that keep track of events or occurrences in an automated system. These powerful instructions allow you to monitor and control various industrial processes with precision and reliability.A counter is essentially a memory location that either increments or decrements based on input conditions. Whether you’re working with an Omron PLC or other brands, understanding counter functionality is crucial for effective automation programming.

How Do Different Types of Counter Instructions Work?

There are several types of counter instructions commonly used in PLC programming:

- Count-Up (CTU) counters

- Count-Down (CTD) counters

- Count-Up/Down (CTUD) counters

Each counter type consists of key elements:

- Input (CU for count up, CD for count down)

- Reset input

- Preset value (PV)

- Accumulated value (ACC)

- Done bit (DN)

The Mitsubishi PLC and other manufacturers implement these counter types with slight variations in their programming software.

What Are the Best Practices for Counter Implementation?

When implementing counters in your ladder logic programming, consider these essential practices:

- Proper Reset Configuration

- Always initialize counters at program start

- Include manual reset capabilities

- Consider automatic reset conditions

- Preset Value Management

- Use variables instead of hard-coded values

- Document preset value changes

- Consider process requirements carefully

Working with Schneider PLCs or any other brand requires attention to these fundamentals for reliable operation.

Common Counter Applications in Industrial Settings

Counters find extensive use in various industrial applications:

| Application | Counter Type | Common Usage |

|---|---|---|

| Part Counting | CTU | Production tracking |

| Batch Processing | CTUD | Recipe management |

| Tool Life | CTD | Maintenance scheduling |

| Conveyor Control | CTU | Package sorting |

Integration with HMI systems allows operators to monitor and adjust counter parameters easily.

Troubleshooting Counter Programming Issues

Common issues with counter programming include:

- Overflow conditions

- Incorrect reset timing

- Missing done bit implementation

- Improper data type selection

Frequently Asked Questions

Implement overflow detection and use appropriate data types for your application range.

Timers measure duration while counters track discrete events or occurrences.

High-speed counters are specifically designed for rapid pulse counting and may not be necessary for slower applications.

Select based on whether you need to count up to a target or down from a starting value.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Key Takeaways

- Counter instructions are essential for tracking events in industrial automation

- Proper implementation requires understanding of different counter types

- Best practices ensure reliable counter operation

- Regular maintenance and monitoring prevent common issues

- Integration with HMI systems improves operator interaction

Remember these critical points when working with PLC counters:

- Always initialize counters properly

- Document your counter implementations

- Consider process requirements carefully

- Test reset conditions thoroughly

- Monitor for overflow conditions

- Maintain proper backup procedures

Contact our automation experts for personalized assistance with your PLC programming needs.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

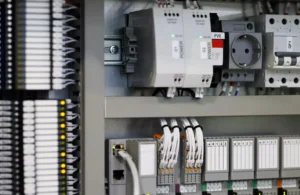

Mastering PLC Panels: A Guide to Reading Wiring Diagrams

As an industrial automation engineer, I deal with PLCs (Programmable Logic Controllers) every day. If you’re like me—deeply interested in automation but often overwhelmed by those complex wiring diagrams—this article is definitely for you.

How to Solve Servo Motor Overheating?

10 Essential Insights About OMRON PLC CJ2 Series Overheating issues with servo motors can disrupt operations and cause unnecessary downtime,

Navigating the Future: Unpacking the Current State of the Industrial Automation Industry

The industrial automation industry is evolving at an unprecedented pace. This article delves into the current state of this dynamic sector, exploring the key trends, market size, and future projections. It’s a must-read because it provides a comprehensive overview of where the industry stands today and where it’s heading, offering valuable insights for anyone interested in or involved with industrial automation.