How Do PLCs Communicate with Each Other?

Table of Contents

From legacy serial interaction (RS-232/ RS-485) to modern-day Industrial Ethernet solutions (EtherCAT, Profinet, Ethernet/IP), this short article describes the typical PLC-to-PLC interaction approaches from an automation designer’s viewpoint.

1. Why Is PLC-to-PLC Communication So Important?

In modern production centers, PLCs are no longer isolated controllers. They establish the ” neural network ” of sensible production line. Reliable PLC interaction allows:

- Coordinated operation across multiple controllers.

- Real-time information exchange with upstream/downstream systems.

- Remote diagnostics and tracking.

- Shared gadget standing for maximized manufacturing.

According to the Industrial Automation Market 2024 Document, over 68% of industrial equipment requires multi-PLC interconnectivity to maintain versatile production and scalable designs.

2. Introduction of Typical PLC Interaction Techniques

PLC communication options vary depending on controller brand, communication distance, real-time requirements, and available budget. The most widely used approaches include:

1. I/O Point-to-Point Signal Interaction

The simplest form of communication, where PLCs exchange standing using electronic or analog I/O factors.

- Advantages: Simple, stable, low cost

- Disadvantages: Extremely minimal information capability, unsuitable for large data exchange.

- Ideal for: Standard interlocking or basic tool sychronisation.

2. Serial Interaction (RS-232/ RS-485)

Still widely used across many PLC families.

| Attribute | RS-232 | RS-485 |

|---|---|---|

| Range | ≤ 15 m | ≤ 1200 m |

| Instruments Supported | Point-to-point | 32+ nodes |

| Common Method | Modbus RTU | Modbus RTU |

| Expense | Reduced | Tool |

3. Modbus Interaction (Modbus RTU/ Modbus TCP)

Among one of the most usual cross-brand interaction methods. Sustained by basically all significant brand names consisting of Omron, Siemens, and Schneider.

- Modbus RTU: Serial-based.

- Modbus TCP: Ethernet-based, quicker transmission.

- Advantages: Open up basic, really simple setup, outstanding compatibility.

- Disadvantages: Master– servant style, a lot less best for complex networks.

A lot of PLCs (e.g., Siemens, Schneider) offer pre-built Modbus collections to streamline arrangement.

4. Profibus-DP (DP Interaction)

A traditional fieldbus commonly made use of in European automation systems.

- Rate: As high as 12 Mbps.

- Nodes: Approximately 126.

- Finest for: Dispersed I/O and mid- to large plants.

5. Industrial Ethernet Interaction

Consists Of Profinet, Ethernet/IP, EtherCAT, and extra. This is currently among one of the most prominent and future-oriented communication strategy.

| Procedure | Real-time Efficiency | Common Application |

|---|---|---|

| Profinet | High | Siemens systems |

| Ethernet/IP | Tool | Rockwell/ Omron |

| EtherCAT | Very high | Movement control, servo networks |

Advantages: Broadband, huge data transfer, versatile geography

Disadvantages: Greater price, needs appropriate network administration.

3. Secret Actions In Configuring PLC Interaction

Although the arrangement procedure differs by brand name, all PLC systems need these fundamental actions:

1. Boot Up Interaction Criteria

Commonly consists of:

- Node address

- Baud rate

- Parity

- Stop bits

Criteria should match on both connecting tools, or interaction can not be developed.

2. Read and Write Information in the PLC Program

Each brand name supplies committed directions, as an example:

- Siemens: MBUS, MB_MASTER, MB_CLIENT.

- Omron: RXDU/TXDU, or EtherNet/IP Tag Information Web Link.

- Mitsubishi: RS, ZR guidelines.

Via these guidelines, Master and Servant tools exchange signs up, little bits, and information blocks.

4. Contrast of PLC Interaction Techniques (Rate, Expense, Range, Applications)

| Technique | Rate | Expense | Range | Normal Usage |

|---|---|---|---|---|

| I/O Signals | ★ | ★ | ≤ 10 m | Fundamental interlocking |

| RS-232 | ★ ★ | ★ | ≤ 15 m | Point-to-point |

| RS-485 | ★ ★ | ★ ★ | ≤ 1200 m | Multi-node RTU |

| Profibus-DP | ★ ★ ★ | ★ ★ | ≤ 100 m | Dispersed control |

| Modbus TCP | ★ ★ ★ | ★ ★ | LAN-dependent | Cross-brand interaction |

| Industrial Ethernet | ★ ★ ★ ★ | ★ ★ ★ | 100 m (copper) | Smart manufacturing facilities, movement control |

5. Just how to Select the Right PLC Interaction Approach

Selecting the ideal communication design requires evaluating 3 considerable aspects:

( 1) Information Quantity

- Tiny: I/O or RS-232

- Tool: RS-485/ Modbus

- Huge: Industrial Ethernet

( 2) Real-time Efficiency

- Movement control: EtherCAT

- General automation: Profinet/ Ethernet/IP

- Fieldbus networks: Profibus

( 3) System Scalability

- Multi-node systems: RS-485/ Profibus/ Ethernet.

- Cross-brand combination: Modbus TCP

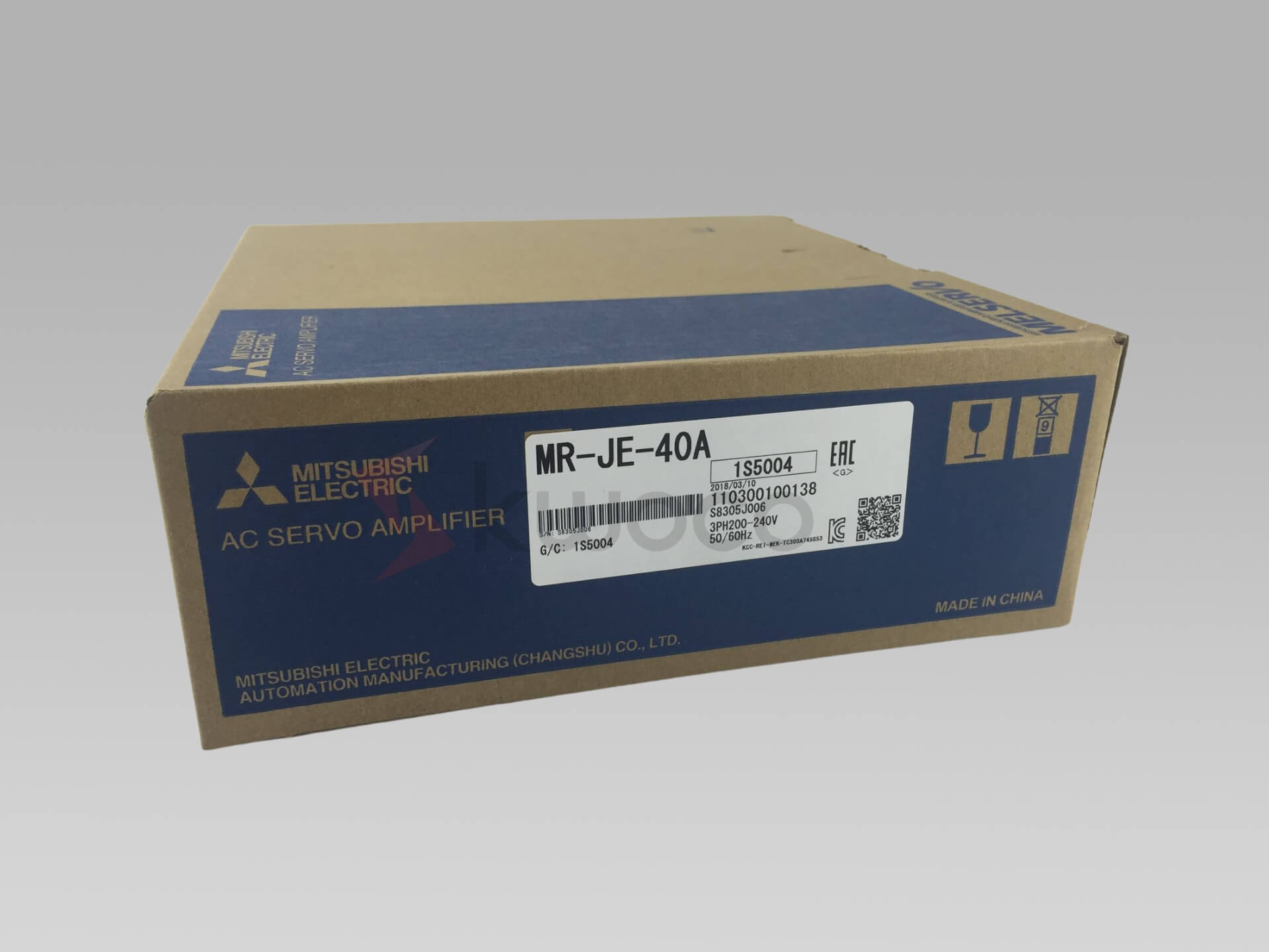

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

PLC-to-PLC interaction approaches vary from typical serial user interfaces to sophisticated Industrial Ethernet systems. Each modern technology uses one-of-a-kind advantages relying on task demands. Designers have to evaluate aspects such as range, real-time efficiency, information quantity, and price when choosing one of the most ideal alternative.

Whether you \’re executing fundamental tool interlock or constructing a full-blown clever production system, trusted PLC interaction is the foundation of automation security.

If you require support choosing the ideal interaction design or sourcing initial Omron, Siemens, or Mitsubishi automation items, do not hesitate to call us for technological advice and real-time supply accessibility.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Understanding PLCs: Uses of Programmable Logic Controllers

Programmable Logic Controllers (PLCs) have become an integral part of modern industrial automation. If you’ve ever wondered how complex machinery and production lines perform tasks with such precision, the answer lies in the use of PLCs.

Troubleshooting Unresponsive Industrial Touch Screen Panels: A Comprehensive Guide

Is your industrial touch screen panel acting up? An unresponsive touch screen can halt production, create frustration, and cost your business valuable time and money. This article provides a comprehensive guide to troubleshooting common industrial touch screen issues. We’ll explore the reasons behind an unresponsive touch, the steps you can take to solve the problem, and when it’s time to call in the professionals. Learn how to ensure your industrial HMIs remain reliable and contribute to smooth manufacturing operations.

PLC vs PC: Key Differences in Industrial Automation

In the realm of industrial automation, the choice between a Programmable Logic Controller (PLC) and a Personal Computer (PC) can significantly impact operational efficiency and system performance. This article delves into the fundamental differences between these two technologies, helping you make informed decisions for your automation needs.