10 Common Omron Servo Drive Alarm Codes Explained

In this article, I’ll share insights into the 10 most common alarm codes in Omron servo drives and how to resolve them.

Table of Contents

1. Overload Alarm Code E01

One of the most frequent issues is the Overload Alarm Code E01. This alarm indicates that the servo drive is experiencing a load exceeding its capacity.

Causes:

- External load is too heavy.

- The servo drive and motor are mismatched.

- Prolonged operation at maximum capacity.

Solutions:

- Check the Load: Ensure that the mechanical load is within the specified limits of the servo motor.

- Verify Compatibility: Confirm that the servo drive and motor are correctly matched in terms of capacity.

- Reduce Operation Time: Avoid running the motor at maximum load for extended periods.

2. Overheat Alarm Code E02

The Overheat Alarm Code E02 signals that the temperature inside the servo drive has exceeded safe operating levels.

Causes:

- High ambient temperatures.

- Poor ventilation around the servo drive.

- Continuous heavy loads causing excess heat.

Solutions:

- Improve Ventilation: Ensure that there is adequate space around the servo drive for air circulation.

- Check Cooling Systems: Inspect fans and heat sinks to make sure they are functioning properly.

- Reduce Ambient Temperature: If possible, lower the temperature of the operating environment.

3. Communication Error Alarm Code E03

When the servo drive cannot communicate with the controller or other devices, it triggers the Communication Error Alarm Code E03.

Causes:

- Faulty communication cables.

- Incorrect communication settings.

- Interference from other electrical devices.

Solutions:

- Inspect Cables: Check all communication cables for damage or loose connections.

- Verify Settings: Ensure that communication parameters match between devices.

- Reduce Interference: Keep communication lines away from high-voltage cables and sources of electromagnetic interference.

4. Following Error Alarm Code E04

The Following Error Alarm Code E04 appears when there is a significant difference between the commanded position and the actual position of the servo motor.

Causes:

- Encoder or sensor malfunction.

- Mechanical obstructions or binding.

- Incorrect gain settings in the controller.

Solutions:

- Check Encoders and Sensors: Inspect for any damage or misalignment.

- Examine Mechanics: Ensure that there are no physical obstacles impeding movement.

- Adjust Controller Settings: Fine-tune the servo gain parameters to improve response.

5. Current Limit Alarm Code E05

The Current Limit Alarm Code E05 indicates that the current flowing through the servo drive exceeds the permissible limit.

Causes:

- Short circuits or ground faults.

- Sudden load changes.

- Drive or motor malfunctions.

Solutions:

- Inspect Wiring: Look for any signs of shorts or grounding issues.

- Stabilize Loads: Gradually introduce load changes to prevent spikes.

- Service Drive/Motor: Have the equipment inspected by a professional if internal faults are suspected.

6. Encoder Error Alarm Code E23

An Encoder Error Alarm Code E23 suggests that the servo drive isn’t receiving proper feedback from the encoder.

Causes:

- Damaged encoder cables.

- Faulty encoder unit.

- Incorrect encoder settings.

Solutions:

- Check Connections: Ensure encoder cables are securely connected and undamaged.

- Test Encoder Functionality: Replace the encoder if it’s malfunctioning.

- Verify Settings: Confirm that encoder parameters are correctly set in the servo drive.

7. Overspeed Alarm Code E24

The Overspeed Alarm Code E24 warns that the motor speed has exceeded the maximum safe limit.

Causes:

- Malfunctioning speed control.

- Incorrect maximum speed parameters.

- External forces causing the motor to accelerate.

Solutions:

- Adjust Parameters: Set the correct maximum speed in the servo drive settings.

- Inspect Control Systems: Ensure that speed control units are functioning properly.

- Monitor External Forces: Identify and mitigate any external influences affecting motor speed.

8. Supply Phase Loss Alarm Code E22

This alarm indicates a Supply Phase Loss Alarm Code E22, meaning there’s an issue with the power supply phases.

Causes:

- One of the power supply phases is missing.

- Blown fuses or tripped breakers.

- Faulty power supply cables.

Solutions:

- Check Power Supply: Verify that all phases are present and the voltage levels are correct.

- Inspect Fuses and Breakers: Replace any blown fuses and reset breakers as needed.

- Examine Cables: Ensure that all power supply cables are connected properly and undamaged.

9. Internal Error Alarm Code E21

The Internal Error Alarm Code E21 reflects a fault within the servo drive’s internal circuits.

Causes:

- Component failures on the control board.

- Firmware corruption.

- Overvoltage or electrical surges.

Solutions:

- Restart the Servo Drive: Sometimes, a simple reboot can clear internal errors.

- Update Firmware: Ensure that the servo drive is running the latest firmware version.

- Consult Manufacturer Support: For persistent issues, contact Omron’s technical support for assistance.

10. Configuration Error Alarm Code E27

When the servo drive’s configuration files are incorrect or corrupted, the Configuration Error Alarm Code E27 is triggered.

Causes:

- Improper parameter settings.

- Corrupted configuration files.

- Incompatible device configurations.

Solutions:

- Restore Default Settings: Reset the servo drive to its factory settings.

- Reconfigure Parameters: Carefully input the correct parameters as per the application’s requirements.

- Backup and Update Configuration Files: Maintain backups and ensure that configuration files are up to date.

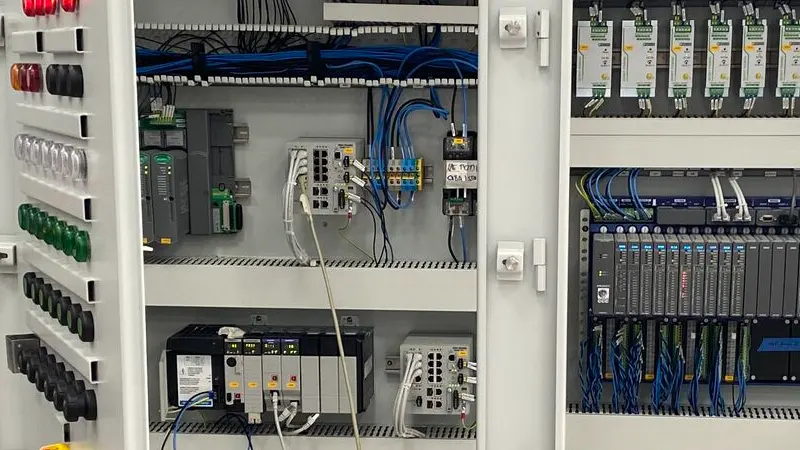

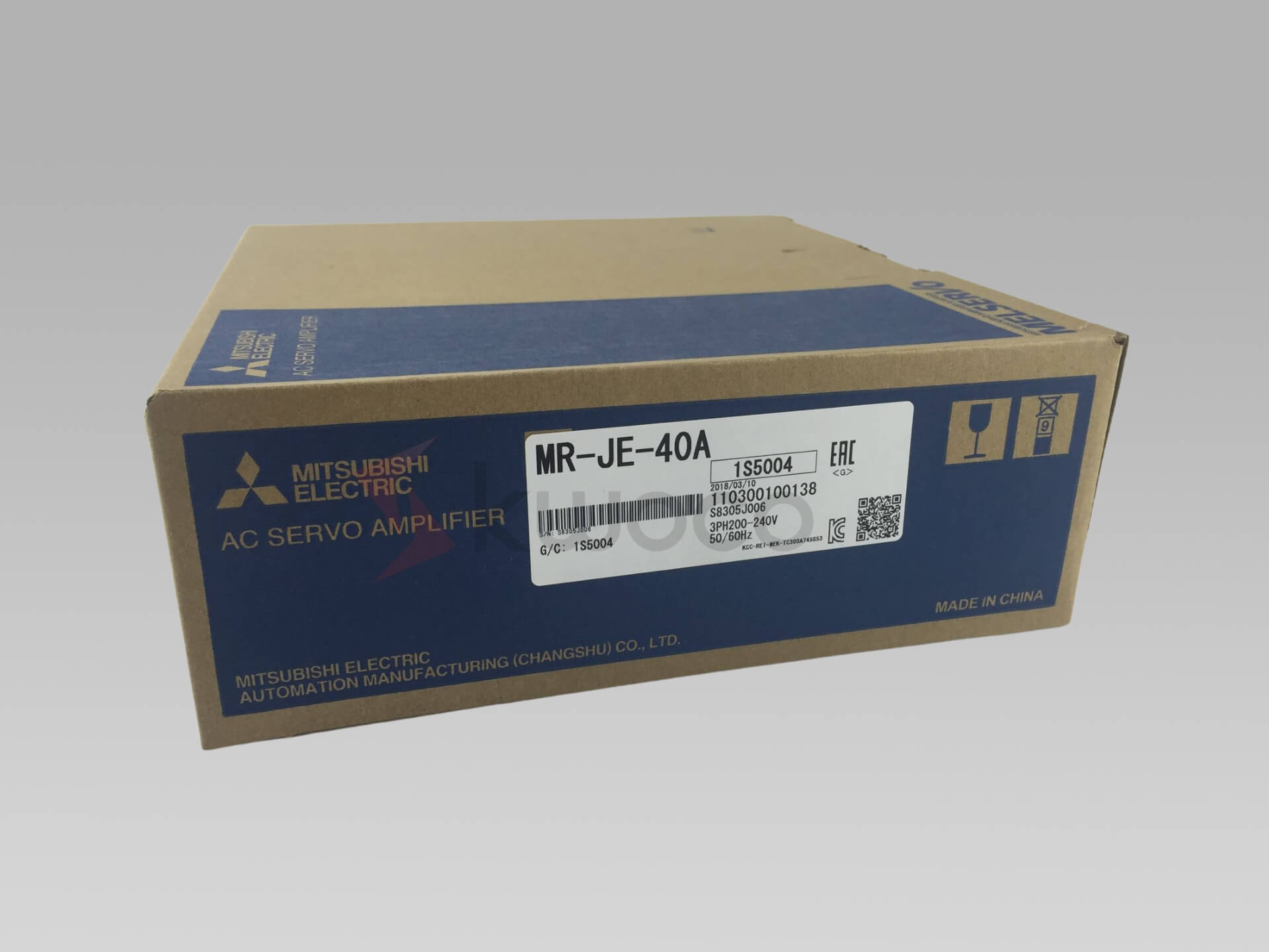

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servos – in stock, ready now!

Conclusion

Understanding these common alarm codes in Omron servo drives can significantly reduce downtime and enhance productivity. Regular maintenance, proper setup, and prompt addressing of alarms will keep your operations running smoothly.

If you have any questions or need further assistance, feel free to reach out to me at [email protected]. Our team at Kwoco is always ready to provide technical support and solutions tailored to your needs.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Allen-Bradley PLC Programming: A Simple Guide

Allen-Bradley PLC Programming: A Simple Guide Frustrated by the complexity of programming Allen-Bradley PLCs? You’re not alone. The process can

Electrical Relay: Understanding the Different Types of Relays

This article delves into the fascinating world of relays, exploring their various types, functionalities, and applications. As a leading provider in the industrial automation sector, we understand the critical role relays play in machinery and equipment factories, manufacturing plants, and factory solution companies. This comprehensive guide will not only enhance your understanding of relays but also demonstrate why our expertise in industrial control products makes us the ideal partner for your automation needs.

Kwoco’s Successful Collaboration with Global Trading Companies

Kwoco’s Successful Collaboration with Global Trading Companies In today’s global market, the reliability of the supply chain directly influences the