Common Faults and Troubleshooting of Omron PLC

Table of Contents

The stable operation of these systems is directly correlated with production efficiency, product quality, and operational costs. Therefore, the ability to rapidly and accurately diagnose and resolve PLC faults is critical for maintaining a company’s core competitiveness.

This document systematically outlines troubleshooting procedures and techniques based on common Omron PLC application scenarios.

1. Power System: The Foundation of Stable PLC Operation

A reliable power supply is the fundamental prerequisite for normal PLC operation. Power supply failures often lead to immediate and complete system shutdowns.

- Common Phenomena: PLC fails to power up entirely (no indicators lit), or exhibits abnormal status upon power-up (e.g., ERROR LED continuously lit or flashing).

- In-depth Cause Analysis:

- External Power Supply: Input voltage fluctuates beyond the PLC’s specified tolerance range (typically ±10% or ±15% – consult the specific hardware manual), loose or oxidized wiring terminals causing high contact resistance, or damaged power cables.

- PLC Power Supply Module: Failure or degradation of internal components (e.g., fuses, capacitors, voltage regulator ICs). For modular PLCs, poor contact between the power supply module and the backplane can also cause issues.

- Efficient Troubleshooting Strategy:

- Verify Input Power: Use a calibrated multimeter to precisely measure the voltage at the input terminals of the PLC power supply module. Ensure the voltage is stable and within the specified range according to the datasheet.

- Inspect Physical Connections: Confirm all power wiring connections are secure, properly terminated, and free from short circuits or breaks. Check the integrity of power plugs and sockets.

- Eliminate External Interference: Investigate if high-power equipment cycling on the same power line is causing disturbances. Consider installing a power line filter or a voltage stabilizer/regulator if necessary.

- Module Substitution Test: If spare parts are available, replace the existing power supply module with an identical model to isolate whether the fault lies within the module itself. Refer to the Omron Official Website for compatible module information and specifications.

2. Input/Output (I/O) Channels: The Bridge to Field Devices

I/O modules manage the signal exchange between the PLC and field devices like sensors and actuators. I/O faults prevent the PLC from accurately sensing field conditions or correctly controlling equipment.

- Common Phenomena: A specific input point remains constantly ON or OFF, failing to reflect the actual sensor status; a specific output point fails to energize its load (e.g., solenoid valve, indicator lamp), or its status is abnormal.

- In-depth Cause Analysis:

- External Wiring & Devices: Malfunctioning sensor or actuator, incorrect wiring (e.g., NPN/PNP mismatch), short circuits or open circuits in the field wiring, poor terminal connections.

- I/O Module Hardware: Failure of internal components like optocouplers, relays, or transistors within the module; poor contact between the I/O module and the backplane.

- Configuration & Program: Incorrect I/O address assignment in the PLC configuration, or program logic errors preventing the corresponding I/O point from being driven correctly.

- Efficient Troubleshooting Strategy:

- Observe Status Indicators: Most Omron I/O modules feature status LEDs for each point, providing an initial indication of whether signals are reaching the module and if the module is attempting to activate outputs.

- Utilize “Force” Function (Use with Caution): Within the programming software (e.g., CX-Programmer or Sysmac Studio), employ the Force ON/OFF functionality. This allows direct testing of whether an output module point can drive its load, or observing if an input point’s status can be manually overridden in the software. This helps differentiate between external field issues and internal module/program problems. Note: Forcing I/O bypasses normal logic and can cause unexpected machine behavior; use extreme care.

- Check External Circuits: Disconnect the field wiring from the module terminals. Use a multimeter, signal generator, or appropriate test equipment to directly test the functionality of the sensor/actuator and the integrity of the connecting cables.

- Module Swapping & Cross-Testing: Exchange the suspect I/O module with an identical, known-good module from another slot or a spare (note that address reconfiguration might be necessary depending on the PLC series and setup). Observe if the fault follows the module or stays with the slot/channel.

3. Program Logic & Memory: Ensuring Control Core Stability

The user program is the core intelligence of the PLC, dictating its control behavior. Errors here directly impact system operation.

- Common Phenomena: Equipment operates contrary to the intended logic sequence, the system halts or generates errors under specific conditions, program download or upload fails.

- In-depth Cause Analysis:

- Program Logic Errors: Incomplete conditional logic, timing conflicts, algorithmic mistakes, race conditions, infinite loops.

- Data Handling Issues: Data overflow, data type mismatches during operations, critical intermediate variables being unintentionally overwritten.

- Memory Problems: Corruption in the program or data memory areas (less common, but possible due to severe electrical noise, end-of-life, or physical shock); battery depletion leading to loss of retentive data (for PLCs using battery-backed RAM).

- Version Incompatibility: Mismatch between the PLC firmware version, the programming software version used, or the program’s dependency on specific function block versions.

- Efficient Troubleshooting Strategy:

- Online Monitoring & Debugging: Leverage the online monitoring capabilities of the programming software. Observe the real-time execution status of ladder rungs or code sections, track variable values, and trace the logic flow step-by-step. Utilize breakpoints to pause execution at specific points for detailed analysis.

- Program Verification & Comparison: Ensure the program currently running in the PLC matches the master version saved on the engineering workstation. Perform regular program backups. Use the software’s compare function if available.

- Interpret Error Codes: When the PLC enters an error state (indicated by the ERROR LED and specific flags/registers), connect with the programming software to read the detailed error code and message. Consult the Omron hardware and instruction reference manuals for the specific PLC series to understand the meaning of the code and recommended actions. Adhering to structured programming practices, like those outlined in IEC 61131-3, can help minimize logic errors.

- Check PLC Status & Diagnostics: Use the diagnostic functions within the programming software to check the overall health of the PLC, including memory status, battery voltage (if applicable), cycle time, and system errors.

4. Communication Network: The Arteries of Information Exchange

Modern automation systems frequently involve networked communication between multiple PLCs, HMIs, VFDs, vision systems, and other intelligent devices.

- Common Phenomena: PLC fails to communicate with a host system (SCADA/HMI) or other network devices, communication data is erroneous or intermittently lost, network status indicators on modules/ports behave abnormally.

- In-depth Cause Analysis:

- Physical Link: Damaged network cables (Ethernet) or serial cables (RS232/485), loose connectors, improper shield grounding, missing or incorrect terminating resistors (essential for RS485/CAN).

- Parameter Configuration: IP address conflicts or subnet mismatches (Ethernet), incorrect baud rate, data bits, stop bits, or parity settings (serial), duplicate station numbers/node addresses, incorrect communication protocol settings.

- Network Load & Interference: Excessive network traffic causing collisions or delays, electromagnetic interference (EMI) corrupting communication signals.

- Module/Port Failure: Hardware malfunction of the PLC’s built-in communication port or an add-on communication module.

- Efficient Troubleshooting Strategy:

- Inspect Physical Connections & Indicators: Verify cable integrity and secure connections at both ends. Observe the Link/Activity LEDs on the communication ports/modules for status information (e.g., link established, data transmitting/receiving).

- Verify Communication Parameters: Meticulously cross-check the communication settings (IP address, subnet mask, gateway, baud rate, parity, node address, etc.) on all devices involved in the specific communication link. Ensure absolute consistency.

- Simplify Network for Testing: Isolate the communication issue by testing point-to-point connections. Disconnect other devices and try communicating between just the PLC and one other device. Use standard tools like the

pingcommand (for Ethernet networks) or specialized serial/network test software. - Utilize Diagnostic Tools: Omron’s software suites, like CX-One (containing Network Configurator) or Sysmac Studio, often include network diagnostic tools. These can help visualize the network, identify connected devices, check node status, and monitor traffic.

- Consult Protocol Documentation: Ensure a thorough understanding of the specific communication protocol being used (e.g., EtherNet/IP, Modbus TCP, RS485 Modbus RTU, Omron’s FINS). Refer to Omron manuals and protocol specifications for details on message structure, timing, and error handling.

5. Other Common Issues and Resolutions

| Fault Category | Potential Causes | Quick Troubleshooting Suggestions | Preventive Measures |

|---|---|---|---|

| Expansion Module Fault | Module hardware failure, poor backplane connection, configuration mismatch (I/O Table), bus cable issue | Check module indicators, reseat the module firmly, verify bus cable connections, double-check I/O table configuration in software | Clean slots periodically, ensure secure mounting, backup configuration |

| Over Temperature | Ambient temperature exceeds specification, poor ventilation/airflow, dust accumulation, excessive CPU/module load | Measure ambient temperature, clean fans and vents, check PLC load percentage (cycle time) | Ensure adequate control panel cooling/ventilation, avoid direct sunlight, perform regular cleaning |

| Software/Compatibility | Incompatible programming software version, missing drivers, OS conflicts on programming PC | Update software/firmware to compatible versions, install correct drivers, check PC environment requirements | Use officially recommended software versions, keep OS updated, document software/hardware configurations |

| Special Function Module | Module hardware failure, incorrect parameter settings (e.g., High-Speed Counter, Pulse Output) | Test with a spare module, meticulously review module manual & parameter settings, use software diagnostics for the module | Fully understand module capabilities & parameter definitions, follow manual instructions precisely |

| System Upgrade Risks | Firmware/program incompatibility after upgrade, data corruption due to interrupted upgrade | Crucially: Backup program & data before upgrading, read release notes carefully, ensure stable power & communication during upgrade | Choose appropriate upgrade windows, seek Omron Technical Support if unsure |

Data Analysis Perspective: Fault Incidence & Downtime Impact (Illustrative Example)

While precise data varies significantly based on application specifics and maintenance practices, industry experience suggests certain trends in fault type distribution. The following table provides illustrative data for reference purposes only:

| Fault Type | Estimated Relative Frequency | Avg. Downtime Impact (Unprepared) | Avg. Downtime Impact (Prepared/Skilled Diagnosis) |

|---|---|---|---|

| Power Supply Fault | Medium | High (Total System Stoppage) | Medium (Requires Spare Part) |

| I/O Fault | High | Medium (Local Function Failure) | Low (Rapid Point Identification & Fix/Replacement) |

| Program Logic Error | Medium-High | Medium to High (Erratic Behavior/Stop) | Medium (Dependent on Debugging Skill) |

| Communication Fault | Medium-High | Medium to High (System Link Failure) | Medium (Parameter Check/Link Test) |

| Hardware Module Fault | Low to Medium | Medium (Requires Spare Part) | Low to Medium (Spare Part Replacement) |

| Environmental/Other | Low | Low to Medium | Low (Improve Environment/Standardize Ops) |

Note: This table is conceptual and does not represent precise statistical data.

Conclusion:

Omron PLCs are fundamental components for achieving efficient and reliable industrial automation. When encountering potential faults, adopting a systematic, evidence-based diagnostic methodology is paramount.

From fundamental checks of power supplies and I/O wiring to complex analysis of program logic and communication networks, each step demands meticulous attention and patience.

Understanding the typical symptoms and root causes of various faults, becoming proficient with Omron’s programming software and diagnostic utilities, and applying the strategies outlined in this guide—along with the data perspective—will empower engineers and technicians to significantly enhance troubleshooting efficiency.

Critically, establishing robust preventive maintenance practices, such as regular inspections, cleaning, program backups, and monitoring the operating environment, can proactively minimize fault occurrences.

This approach ensures the maximum performance and longevity of Omron PLC systems, safeguarding production stability and ultimately achieving cost reduction and efficiency improvements.

For particularly complex or persistent issues, consulting official Omron documentation or contacting Omron Technical Support is always a recommended course of action.

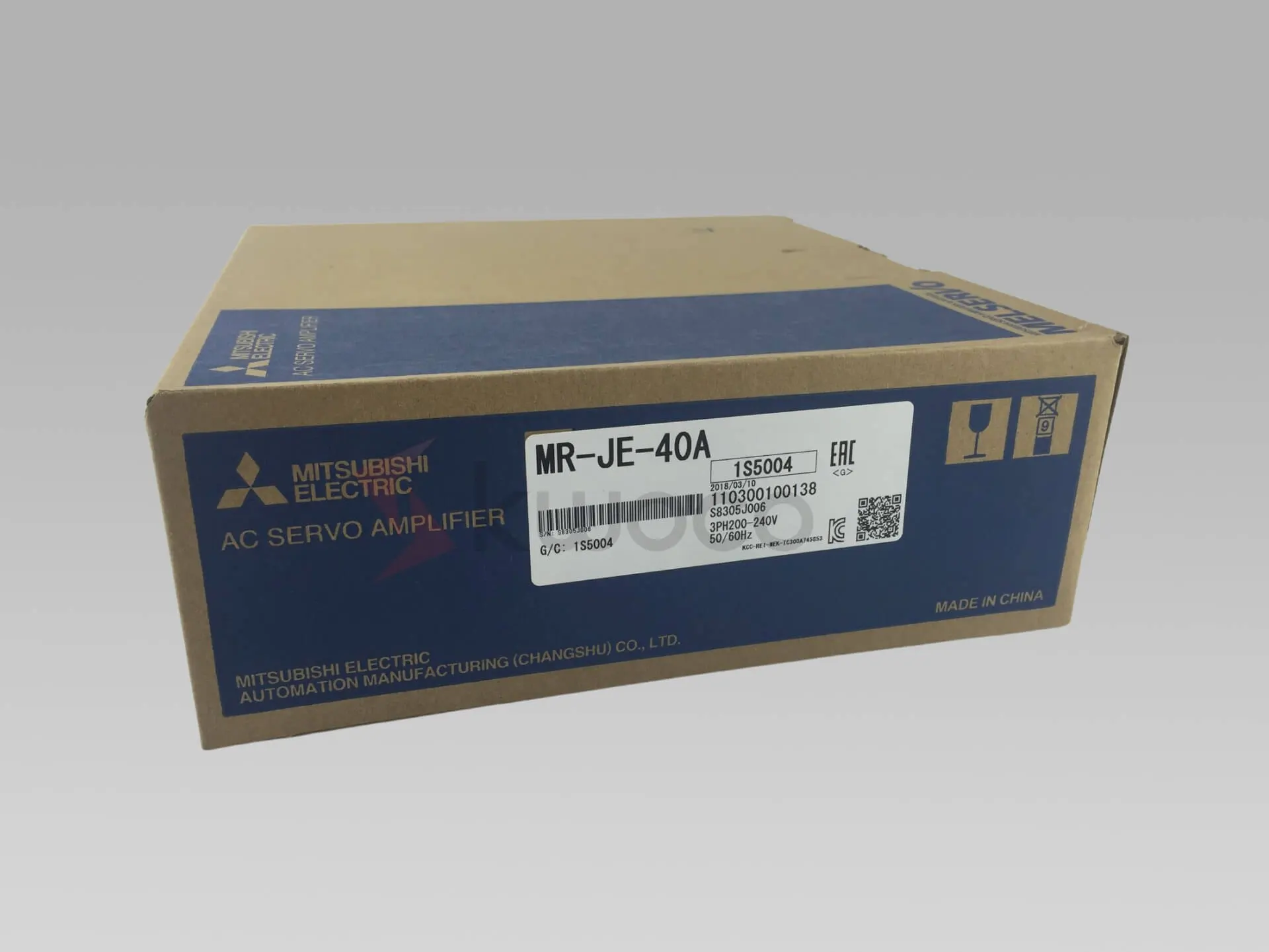

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

The Core Engine of Industrial Automation: A Comprehensive Guide to PLC Principles, Classification, and Selection

With the fast innovation of Sector 4.0 and Smart Production, the PLC (Programmable Logic Controller) has actually come to be the essential “digital brain” of contemporary commercial assembly line.

Cooperation Cases Between Kwoco and Equipment Manufacturers

Cooperation Cases Between Kwoco and Equipment Manufacturers KWOCO has become the preferred supplier for an increasing number of equipment manufacturers.

What are Examples of PLC Inputs and Outputs?

What are Examples of PLC Inputs and Outputs? In industrial automation, PLC (Programmable Logic Controller) systems are the brains behind