Contactor vs Relay: Understanding the Difference Between Contactors and Relays

Table of Contents

1. What is a Relay and How Does It Work?

A relay is an electromagnetic switch that uses a small electrical current to control a larger electrical current in a circuit. When a small current is applied to the relay coil, it generates a magnetic field that moves the armature of the relay, thereby opening or closing the contacts.

Relays are commonly used in control circuits to switch low-power signals. They act as a bridge between a low-voltage control circuit and a higher-voltage power circuit. For instance, in industrial automation systems, relays can be used to turn on or off sensors, indicators, or small motors. Their ability to isolate the control circuit from the power circuit enhances safety and prevents damage to sensitive electronic components.

Relays are suitable for applications where the current and voltage are relatively low. They are often found in consumer electronics, automotive systems, and telecommunications equipment. Standard relays are designed to handle currents up to around 10 amperes and are compact and efficient for their size.

2. What is a Contactor and What is Its Function?

A contactor is a type of electrical switch used to switch a high-power circuit on or off. Similar to a relay, a contactor is an electromechanical device, but it is designed to handle much higher currents and voltages.

When a control voltage is applied to the contactor coil, it creates a magnetic field that pulls the contacts together, allowing current to flow through the power circuit. Contactors are typically used in applications involving large motors, lighting systems, and heating elements.

One key feature of contactors is their ability to handle high inrush currents, which are common when starting motors. Contactors are designed with arc suppression mechanisms to quickly extinguish any electrical arcs that form when the contacts open or close, ensuring safe and reliable operation. They often come with auxiliary contacts for additional control functions.

3. What’s the Key Difference Between Contactors and a Relay?

The key difference between contactors and relays lies in their capacity and intended use. Contactors are designed to handle higher currents and voltages, typically above 10 amperes and up to several thousand volts. Relays, on the other hand, are used for lower power applications, usually below 10 amperes.

Here’s a table summarizing the main differences:

| Feature | Contactor | Relay |

|---|---|---|

| Current Rating | High (typically above 10A) | Low (typically below 10A) |

| Voltage Rating | High (up to several thousand volts) | Low to moderate |

| Application | Switching high-power loads (e.g., motors, lighting systems, heating elements) | Switching low-power loads (e.g., control signals, small motors, indicators) |

| Arc Suppression | Equipped with arc suppression mechanisms | Generally not equipped with arc suppression (except for specialized power relays) |

| Contacts | Typically normally open (NO); can have normally closed (NC) for specific applications | Can be normally open (NO), normally closed (NC), or changeover (CO) |

| Size | Larger and more robust | Smaller and more compact |

| Auxiliary Contacts | Often includes auxiliary contacts for additional control functions. | May or may not include auxiliary contacts. |

| Cost | Generally more expensive due to their robust construction and ability to handle high power | Generally less expensive |

| Durability | Designed for frequent switching and high mechanical and electrical endurance | Designed for less frequent switching and lower endurance |

| Typical Use Case | Industrial machinery, HVAC systems, large electrical panels, automation of industrial processes. | Consumer electronics, automotive systems, telecommunications, automation of processes |

Contactors often feature larger contacts and robust construction to withstand the mechanical stress and heat generated during operation. Relays are generally smaller and designed for lighter duty. Unlike relays, contactors are almost exclusively designed with normally open contacts, as they are typically used to energize a circuit when activated.

4. Are Contactors and Relays the Same Thing?

While both contactors and relays perform the function of switching electrical circuits, they are not the same. The primary distinction is their application and the amount of power they are designed to handle. A contactor is used to switch high-power loads, while a relay handles low-power loads.

Think of it this way: a relay is like a light switch in your home, designed to control a small amount of power. A contactor is like the main circuit breaker in your electrical panel, capable of handling the entire power supply to your house.

5. How Do I Choose Between a Contactor or Relay for My Application?

Choosing between a contactor or relay depends on the specific requirements of your application.

- Consider the Load: If you need to control a high-power device like a large motor or a heating system, a contactor is the appropriate choice. For low-power devices or control signals, a relay will suffice.

- Evaluate the Current and Voltage: Contactors are designed to operate at higher voltages and currents. If your application involves voltages above 240V and currents above 10A, a contactor is necessary. For lower voltages and currents, a relay is suitable.

- Assess the Switching Frequency: Contactors are designed for frequent switching and can withstand the wear and tear associated with it. Relays are better suited for applications where switching is less frequent.

- Safety and Reliability: Contactors include features like arc suppression to ensure safe operation under high loads. Relays offer reliable performance for low-power applications but may not be suitable for high-power switching due to the lack of arc suppression.

- Cost: Relays are generally less expensive than contactors. However, using a relay where a contactor is needed can lead to failure and potential safety hazards.

6. What are the Different Applications of Relays?

Relays have various applications across different industries. Here are some common examples:

- Control Circuits: Relays are commonly used in control circuits to switch low-power signals. They can be used to activate indicators, alarms, or small motors based on input from sensors or other control devices.

- Automotive Systems: Relays are used in vehicles to control headlights, wipers, and other electrical components. They allow a small switch on the dashboard to control a larger current to the device.

- Telecommunications: Relays are used in switching equipment to connect and disconnect phone lines. Solid-state relays are often used in modern telecommunication systems for their fast switching speed and long lifespan.

- Consumer Electronics: Relays can be found in various household appliances, such as washing machines and refrigerators, to control different functions based on user settings or sensor inputs.

Relays are used in applications where isolation between the control circuit and the power circuit is necessary. They provide a safe and reliable way to control electrical devices without exposing the control circuit to high voltages or currents. Relays aren’t always the best choice for applications with extremely high switching frequencies.

7. What are the Primary Applications of Contactors?

Contactors are essential components in many industrial and commercial settings. Their primary applications include:

- Motor Control: Contactors are commonly used to start and stop electric motors, especially large ones found in industrial machinery. They can handle the high inrush currents associated with motor startup and provide a reliable means of controlling motor operation.

- Lighting Systems: In large buildings or outdoor areas, contactors are used to switch lighting circuits on and off. They can be controlled by timers, light sensors, or building management systems.

- HVAC Systems: Contactors are used in heating, ventilation, and air conditioning systems to control the operation of compressors, fans, and other high-power components.

- Power Distribution: Contactors can be used in electrical panels to switch power to different sections of a building or facility. They provide a safe and efficient way to manage the distribution of electrical power.

Contactors are used in applications where high currents and voltages are present. They are designed to withstand the demands of heavy-duty use and ensure the safe operation of electrical equipment. Contactors are often fitted with safety interlocks and thermal overload protection. Use contactors when dealing with high-power loads.

8. Can Contactors and Relays Be Used Interchangeably in an Electrical System?

No, contactors and relays cannot be used interchangeably in most cases. Using a relay in place of a contactor can lead to failure due to the relay’s inability to handle high currents and voltages. This can result in overheating, contact welding, and potential damage to the electrical system.

Conversely, using a contactor where a relay is sufficient is generally overkill and can be more expensive. While a contactor could technically perform the function of a relay, it is not cost-effective or practical.

9. How Do Contactors and Relays Impact the Safety of an Electrical Circuit?

Contactors and relays play a crucial role in ensuring the safety of an electrical circuit. Contactors are designed with safety features such as arc suppression to prevent electrical arcs from forming when the contacts open or close. This is particularly important when switching high-power loads, as arcs can cause damage to equipment and pose a fire hazard.

Relays provide safety by isolating the control circuit from the power circuit. This prevents high voltages and currents from reaching sensitive electronic components, reducing the risk of damage or malfunction.

Proper selection and use of contactors and relays are essential for maintaining the safety and reliability of an electrical system. Using the wrong device can compromise safety and lead to costly repairs or downtime.

10. What Maintenance is Required for Contactors and Relays?

Regular maintenance is important to ensure the proper functioning of contactors and relays.

- Inspection: Periodically inspect contactors and relays for signs of wear, such as pitted or burned contacts. Check for loose connections and tighten them if necessary.

- Cleaning: Dust and debris can accumulate on contacts, leading to poor connections. Clean the contacts with a suitable contact cleaner to ensure proper conductivity.

- Testing: Test the operation of contactors and relays to ensure they are switching properly. For contactors, check the coil resistance and the continuity of the main contacts. For relays, verify the operation of the coil and the switching of the contacts.

- Replacement: Replace any contactors or relays that show signs of damage or are not functioning correctly. Using worn or damaged devices can compromise the safety and reliability of the electrical system.

Frequently Asked Questions

The primary difference between contactor and relay lies in their power handling capacity. Contactors are designed for high-power applications, while relays are used for low-power applications.

No, using a relay instead of a contactor in a high-power application can lead to failure and potential safety hazards. Relays are not designed to handle the high currents and voltages that contactors are built for.

Use a contactor when you need to control high-power loads, such as motors, lighting systems, or heating elements. Contactors are designed to handle high currents and voltages and include features like arc suppression for safe operation.

Signs of a failing contactor or relay include:

Failure to switch on or off

Buzzing or humming noises

Visible damage to contacts (e.g., pitting, burning)

Overheating

If you notice any of these signs, it’s important to inspect and potentially replace the device to ensure the safety and reliability of your electrical system.

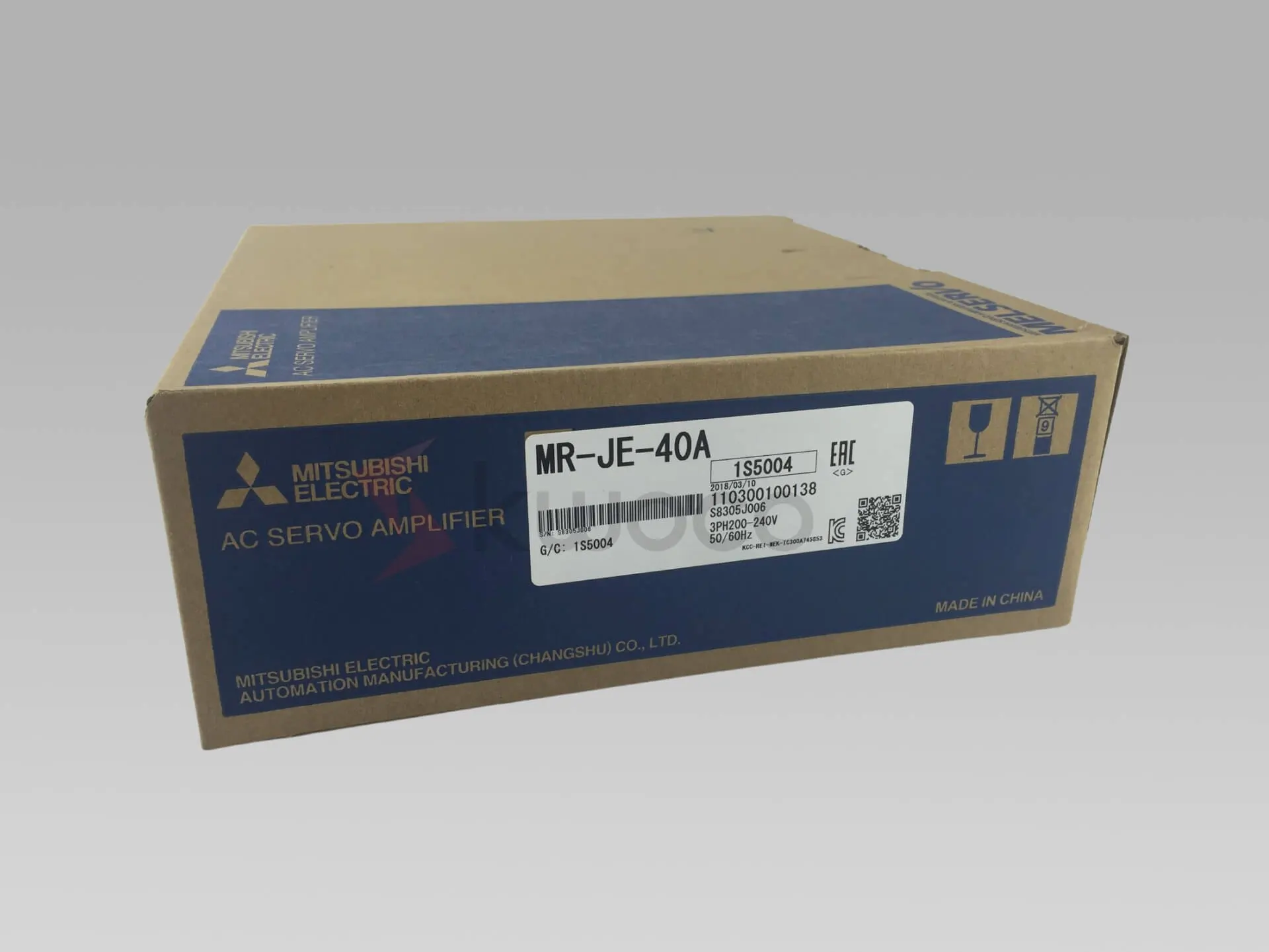

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servo – in stock, ready now!

Conclusion

- Contactors and relays are both electrical switches, but they are designed for different applications.

- Contactors are used for high-power loads, while relays are used for low-power loads.

- The key difference between contactors and relays lies in their current and voltage ratings, as well as their construction and safety features.

- Choosing the right device depends on the specific requirements of your application, including the load, current, voltage, and switching frequency.

- Proper maintenance of contactors and relays is essential for ensuring the safety and reliability of your electrical system.

- Using a relay where a contactor is needed can lead to failure and safety hazards, while using a contactor where a relay is sufficient is generally overkill and not cost-effective.

- If you are dealing with industrial automation needs, consider Mitsubishi PLC for reliable control solutions.

- For high-performance motor control, explore Delta Servo options.

- Enhance your machinery with high-quality Proface HMI for user-friendly interfaces.

- Ensure precise and efficient movement with Mitsubishi Servo systems.

- Optimize your power usage with reliable Schneider inverters.

By understanding these key points, you can make informed decisions when selecting and using contactors and relays, ensuring your operations run smoothly, safely, and efficiently. If you have any questions or need further assistance with your industrial automation needs, please don’t hesitate to contact us.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

How to Adjust a Photoelectric Sensor: Expert Guide

Adjusting a photoelectric sensor might seem complex, but with the right approach, it becomes a straightforward task. Today, I want to share my expertise on how to adjust a photoelectric sensor effectively.

What is PLC Programming? An Introductory Tutorial on PLC Programming

In modern commercial production, PLC (Programmable Logic Controller) programs has actually turned into one of the essential automation innovations. PLCs are widely utilized in industrial automation control systems, and their performance, integrity, and versatility have actually efficiently replaced typical relay control systems.

24VDC vs 120VAC: Understanding the Differences in Automation

When selecting control voltages for industrial automation, two common choices are 24VDC and 120VAC. But how do you decide which one is right for your application? In this article, we will break down the key differences between 24VDC and 120VAC, explore their uses in automation systems, and help you make an informed decision based on your needs.