Allen-Bradley PanelView Selection Guide: Choose the Right HMI

Table of Contents

What Makes Allen-Bradley PanelView the Industry Standard in HMI Solutions?

- Modern touch screen interfaces

- Robust communication protocols

- Seamless integration with existing systems

- Advanced configuration options

How to Choose Between PanelView Plus 7 Standard and Performance Models?

When selecting between PanelView Plus 7 models, consider these key factors:

| Feature | Standard Model | Performance Model |

|---|---|---|

| Memory | 512 MB RAM | 1GB RAM |

| Display Sizes | 4″ to 12″ | 7″ to 19″ |

| Ethernet Ports | Single | Dual |

| VNC Server | Basic | Advanced |

The PanelView Plus 7 performance model is particularly appropriate for applications that require advanced functionality and enhanced connectivity options.

Understanding PanelView 800 Series Capabilities

The PanelView 800 terminal offers:

- Compact design for space-constrained applications

- Integration with Micro 800 controllers

- Enhanced motion control capabilities

- Built-in Ethernet connectivity

These features make it ideal for general-purpose motor control applications and smaller automation projects.

What Are the Key Configuration and Communication Options?

- Communication Protocols

- EtherNet/IP

- DF1

- DH+ (select models)

- Software Integration

- FactoryTalk View compatibility

- Studio 5000 integration

- PDF viewer functionality

Frequently Asked Questions

Consider viewing distance, information density, and installation space constraints. For operator stations, 7″ to 12″ displays are most common.

They run on Windows CE operating system, providing robust reliability and familiar user interface elements.

Yes, through the built-in VNC server functionality, enabling remote monitoring and control.

Yes, it maintains compatibility with legacy systems while offering modern features.

Yes, our experts are available to guide you in selecting the perfect products tailored to your project’s unique requirements, ensuring optimal performance.

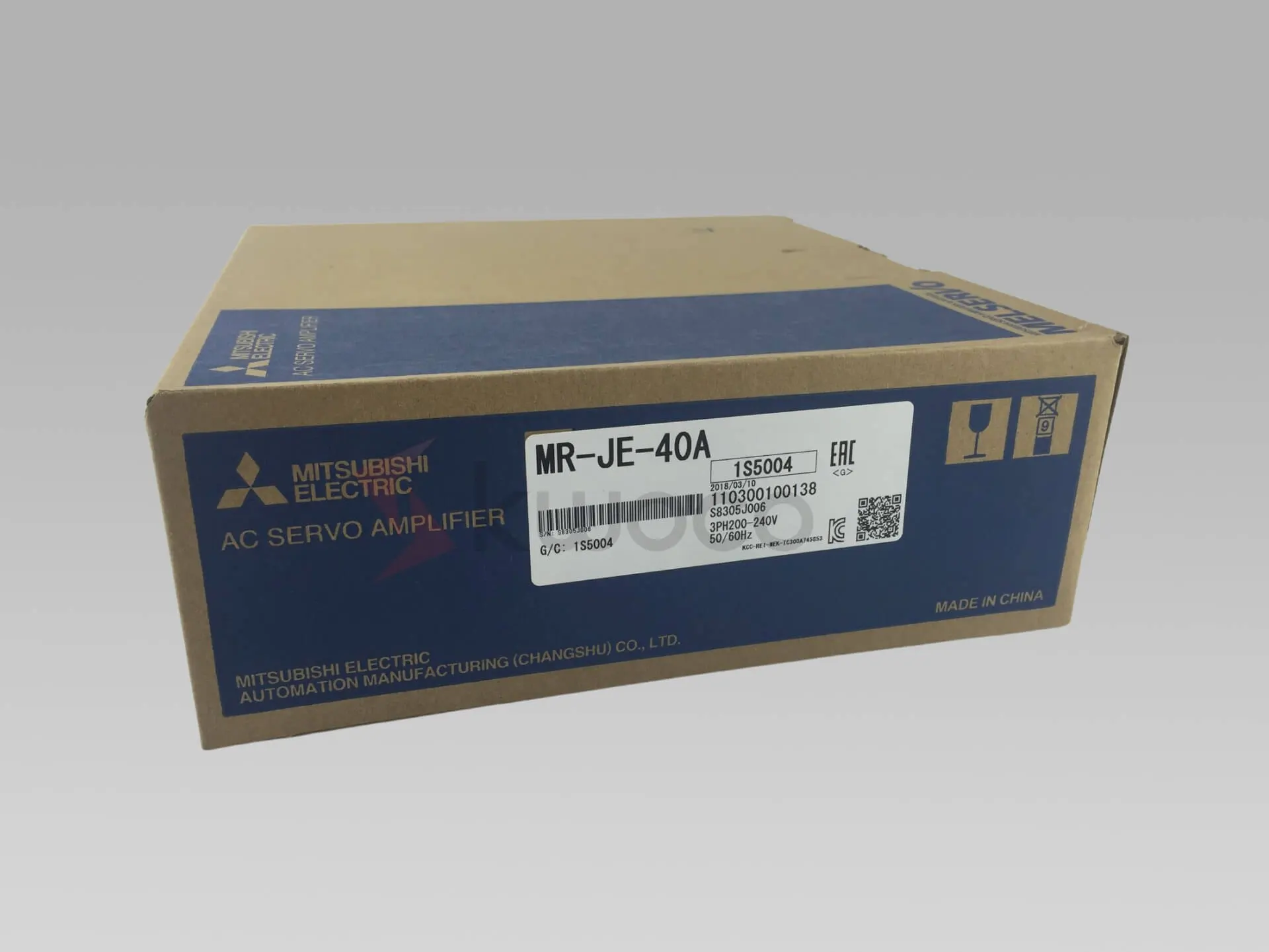

Power your projects with brand-new, original Allen-Bradley, Omron, Mitsubishi, HMI – in stock, ready now!

Conclusion

- PanelView Plus 7 offers both standard and performance versions for different application needs • Built-in Ethernet connectivity ensures seamless integration • Multiple display sizes available from 4″ to 19″ • Advanced configuration options support various industrial protocols • Remote access capabilities through VNC server functionality

Explore our complete automation solutions

This guide helps you navigate the selection process for Allen-Bradley PanelView products. For specific application requirements or detailed specifications, contact our industrial automation experts.

Remember to consider:

- Application requirements

- Budget constraints

- Integration needs

- Future expansion possibilities

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Essential Guide to PLC Systems for Engineers

Essential Guide to PLC Systems for Engineers Do you want to streamline your industrial automation processes but are unsure where

Demystifying Magnetic Switches: A Comprehensive Guide for Industrial Applications

This article provides an in-depth look at magnetic switches, exploring their function, benefits, and applications, particularly within industrial settings. Whether you’re a seasoned engineer or new to the world of industrial automation, this guide will equip you with a thorough understanding of how magnetic switches can enhance your operations. We aim to demystify these devices and showcase why they are a critical component in modern manufacturing and automation systems.

Top 8 Omron PLC Suppliers in the Europe

Top 8 Omron PLC Suppliers in The Europe With over a decade of experience in the industrial automation industry, we’ve