PLC Guide: Concepts, Applications & Wiring Essentials

Table of Contents

Introduction: The “Brain” in the Wave of Automation

In today’s rapidly advancing industrial automation landscape, production efficiency, flexibility, and reliability are critical metrics for manufacturing capability.

Traditional, complex relay control circuits struggle to meet modern industry’s demands for intricate logic, rapid response times, and convenient maintenance.

It is against this backdrop that the Programmable Logic Controller (PLC) emerged and swiftly established itself as the central “brain” of automation control systems.

This document will systematically guide you through the world of PLCs, explaining their fundamental principles, wide-ranging applications, and essential wiring techniques.

Part 1: Unveiling the PLC – Core Concepts and Advantages

1. What is a PLC?

A PLC, or Programmable Logic Controller, is a digital electronic system specifically designed for operation in industrial environments.

It utilizes programmable memory to store user-oriented instructions for implementing functions such as logical operations, sequence control, timing, counting, and arithmetic operations.

Through digital or analog input/output (I/O) modules, it controls various types of machines or production processes.

2. Comparison with Traditional Control: Why Choose a PLC?

Before the widespread adoption of PLCs, industrial control primarily relied on hardwired logic circuits composed of relays, contactors, timers, etc. Conceptually:

- Traditional Circuits (Relay Logic):

- Fixed Functionality: Once wired, changing the control logic is difficult and labor-intensive.

- Wiring Complexity: The number of components and the amount of wiring increase exponentially with control logic complexity.

- Difficult Maintenance: Troubleshooting requires point-by-point checking of physical connections, which is time-consuming.

- Limited Contacts: Physical contacts have finite quantity and lifespan limitations.

- Poor Scalability: Adding new functions often necessitates significant redesign and rewiring.

- PLC Control Systems:

- High Flexibility: Control logic resides in a software program. Modifying functionality typically involves only changing the program code, without altering hardware wiring. For instance, changing input button X00 from controlling output Y001 to controlling Y002 requires only a minor modification in the programming software.

- Simplified Design & Wiring: Inputs (e.g., buttons, sensors) and outputs (e.g., indicator lamps, motor contactor coils) connect directly to the PLC’s I/O modules, drastically reducing external wiring complexity.

- Powerful Functionality: PLCs offer a rich instruction set, easily implementing complex logic, timing, counting, data manipulation, etc. Internal software contacts (Normally Open/Normally Closed) can be used virtually without limitation.

- Ease of Maintenance & Diagnostics: Programming software provides online monitoring capabilities, allowing real-time observation of program execution status and I/O signals, facilitating rapid fault localization.

- High Reliability & Scalability: Designed for harsh industrial environments, PLCs exhibit strong noise immunity. Their modular design allows for easy expansion of I/O points or the addition of specialized function modules as requirements evolve.

Table 1: Comparison of PLC Systems vs. Traditional Relay Control Systems

| Feature | Traditional Relay Control System | PLC Control System |

|---|---|---|

| Control Logic Implementation | Hardware Wiring (Hardwired) | Software Programming (Software Program) |

| Flexibility/Modification | Low, requires rewiring | High, modify program |

| System Complexity | Increases sharply with scale | Primarily in software, hardware simpler |

| Reliability | Contacts prone to wear, environment sensitive | High, industrial design, noise immune |

| Maintenance/Diagnostics | Difficult, trace physical wires | Easier, via software online monitoring |

| Functionality | Basic logic, timing, counting | Complex logic, math, comms, advanced control |

| Physical Size | Larger | Relatively Compact |

| Standardization | Low | High, common standards across brands |

| Cost (Simple System) | Potentially Lower | Potentially Higher |

| Cost (Complex System) | High | Relatively Lower |

Part 2: Core Functions and Application Domains of PLCs

PLC capabilities extend far beyond basic switching control. Modern PLCs are versatile powerhouses, with applications generally categorized into these five areas:

- Digital Control (Discrete Control): This is the most fundamental and widespread PLC application. It involves processing ON/OFF signals (digital inputs) from devices like pushbuttons, switches, and sensors, and driving actuators such as indicator lamps, relays, and solenoid valves (digital outputs) based on the program logic. This forms the basis for equipment start/stop sequences and sequential operations.

- Motion Control: Many PLCs, particularly mid-range to high-end models, feature high-speed pulse output points. These outputs generate high-frequency pulse trains to precisely control stepper motors or servo drives, enabling complex tasks like precision positioning, velocity control, and trajectory tracking. This is crucial in packaging machinery, CNC machines, robotics, and similar applications.

- Analog Control: Industrial processes often involve continuously varying physical quantities like temperature, pressure, flow rate, and level. PLCs use analog input modules to acquire signals (typically 4-20mA or 0-10V) from transmitters and sensors. After internal processing (A/D conversion, filtering, scaling), analog output modules control devices like modulating valves or Variable Frequency Drives (VFDs) to achieve closed-loop control. Common examples include temperature regulation and constant pressure water supply. Many PLCs incorporate built-in PID (Proportional-Integral-Derivative) control function blocks for precise process control. Learn more about PID Controllers

- Data Handling (Data Processing): PLCs possess robust capabilities for mathematical operations (addition, subtraction, multiplication, division, trigonometric functions, etc.), logical operations, data comparison, data transfer, and sorting. They can collect production data for analysis, processing, and storage. Examples include counting products, calculating cycle times, managing recipes, and implementing complex workflow logic (e.g., queue management systems).

- Communication & Networking: Modern automation emphasizes interconnectivity. PLCs are equipped with various communication ports (e.g., RS232, RS485, Ethernet) and support multiple industrial protocols (e.g., Modbus, Profibus, ProfiNet, EtherNet/IP). This enables PLCs to:

- Communicate with Human-Machine Interfaces (HMIs)/Touch Screens: Create graphical interfaces for monitoring device status, setting parameters, and manual operation, replacing numerous physical buttons and lamps.

- Communicate with Supervisory Computers/SCADA Systems: Facilitate data acquisition, remote monitoring, and plant management.

- Network with other PLCs or intelligent devices (like VFDs, instruments): Build Distributed Control Systems (DCS) or enable coordinated operation between machines.

- Explore common industrial protocols: Modbus Organization, ODVA (manages EtherNet/IP et al.)

Part 3: PLC Wiring Fundamentals

Correct wiring is paramount for the stable operation of any PLC system. PLC wiring primarily involves the input and output terminals.

1. Input Wiring: PLC inputs receive signals from external field devices.

- Connectable Devices: Pushbuttons, selector switches, limit switches, proximity sensors (inductive), photoelectric sensors, magnetic switches (reed switches, often for cylinder position), fiber optic amplifiers, U-shaped (slot) sensors, etc. Essentially, these devices provide a switching signal to the PLC.

- Basic Circuit Elements: A complete input circuit requires a power source, a switching element (the input device), and the load (in this case, the PLC input point’s optocoupler).

- Input Types and Connection (Example: Mitsubishi FX3U, DC24V Supply):

- Common Terminal (S/S or COM): PLC inputs are typically isolated internally via optocouplers. One side of all input optocouplers is connected internally to a common terminal. For external wiring, this common terminal must be connected to one pole of the external DC power supply.

- Sink Input (NPN Logic): The common terminal (S/S) is connected to the positive (+24V) of the external DC power supply. The input device (e.g., pushbutton) connects between the PLC’s X input terminal and the negative (0V) of the power supply. When the button is pressed, current flows from +24V -> S/S -> internal optocoupler -> X terminal -> button -> 0V, completing the circuit, and the PLC registers an ON input. This configuration is used for NPN-type sensors.

- Source Input (PNP Logic): The common terminal (S/S) is connected to the negative (0V) of the external DC power supply. The input device connects between the PLC’s X input terminal and the positive (+24V) of the power supply. When the button is pressed, current flows from +24V -> button -> X terminal -> internal optocoupler -> S/S -> 0V. This configuration is used for PNP-type sensors.

- 2-Wire Device Connection: Devices like standard pushbuttons, limit switches, and 2-wire magnetic switches are connected according to the selected Sink or Source wiring scheme. Note: 2-wire magnetic switches often have polarity (Brown and Blue wires). Connect correctly based on the PLC input type (Sink/Source) and current flow. General rule: For Sink input (S/S to +24V), connect Brown wire to X input, Blue wire to 0V. For Source input (S/S to 0V), connect Brown wire to +24V, Blue wire to X input. (Always verify device specifications).

- 3-Wire Sensor Connection (e.g., Photoelectric/Proximity):

- NPN Sensor: Brown wire to +24V, Blue wire to 0V, Black signal wire to the PLC’s X input terminal. The PLC input must be configured/wired for Sink Input (S/S connected to +24V).

- PNP Sensor: Brown wire to +24V, Blue wire to 0V, Black signal wire to the PLC’s X input terminal. The PLC input must be configured/wired for Source Input (S/S connected to 0V).

2. Output Wiring: PLC outputs drive external loads.

- Connectable Loads: Indicator lamps, solenoid valves (for pneumatic/hydraulic control), interposing relays, contactors (for high-power motors), Solid State Relays (SSRs, for heaters, etc.), control signals for VFDs, stepper/servo drives, etc.

- Output Types: PLC output modules primarily come in three types, chosen based on load characteristics and application needs.

- Relay Output (e.g., MR suffix in Mitsubishi):

- Principle: Uses internal miniature electromechanical relays. When the program energizes an output coil (Y), the corresponding internal relay contact closes, completing the external load circuit.

- Advantages: Can drive both AC and DC loads, wide voltage range, relatively high current capacity, good electrical isolation, lower cost.

- Disadvantages: Finite mechanical lifespan (typically hundreds of thousands to millions of cycles), slow switching speed (~10ms), unsuitable for high-frequency switching (like PWM or high-speed pulse outputs). Recommended switching frequency below ~0.1 Hz (6 times/minute) to maximize lifespan.

- Wiring: Each output point (or group) has a common terminal (COM). Connect one side of the load to the Y output terminal, the other side to one pole of the load power supply. Connect the other pole of the load power supply to the corresponding COM terminal. The COM connection is flexible regarding polarity (DC) or line/neutral (AC).

- Transistor Output (e.g., MT suffix in Mitsubishi):

- Principle: Uses internal power transistors (typically MOSFETs).

- Advantages: Extremely fast switching speed (microseconds), no mechanical wear, very long lifespan, ideal for high-frequency applications like driving stepper/servo drives (pulse outputs) and PWM control (dimming/speed).

- Disadvantages: Can only drive DC loads. Lower tolerance for overloads and inrush currents; external protection (e.g., flyback diode for inductive loads) is often necessary. Exhibits small leakage current when OFF.

- Wiring: Available as Sink (NPN) or Source (PNP) types.

- Sink Output: The common terminal (COM) connects to the negative (0V) of the external load power supply. Connect one side of the load to the positive (+V) of the supply, the other side to the PLC’s Y output terminal. When Y turns ON, it connects the load to 0V.

- Source Output: The common terminal (COM) connects to the positive (+V) of the external load power supply. Connect one side of the load to the negative (0V) of the supply, the other side to the PLC’s Y output terminal. When Y turns ON, it supplies +V to the load.

- Triac Output (Thyristor Output, e.g., MS suffix in Mitsubishi):

- Principle: Uses internal Triacs (a type of bidirectional thyristor).

- Advantages: Fast switching speed, long lifespan, suitable for driving AC loads, especially small AC contactors, solenoid valves, etc.

- Disadvantages: Can only drive AC loads. Typically features zero-crossing switching (a benefit for reducing noise, but prevents phase angle control). Exhibits some leakage current when OFF. Susceptible to damage from voltage spikes/surges.

- Wiring: Similar concept to relay output wiring (load connected between Y and power, COM connected to the other side of power), but strictly for AC circuits.

- Relay Output (e.g., MR suffix in Mitsubishi):

Table 2: Comparison of PLC Output Module Types

| Feature | Relay Type (MR) | Transistor Type (MT) | Triac Type (MS) |

|---|---|---|---|

| Load Type Driven | AC / DC | DC Only | AC Only |

| Switching Speed | Slow (~10ms) | Very Fast (<1ms) | Fast (<1ms) |

| Switching Frequency | Low (<0.1Hz recommended) | Very High (kHz range) | Relatively High |

| Lifespan | Limited (Mechanical) | Long (Solid-State) | Long (Solid-State) |

| Current Capacity | Higher (e.g., 2A) | Lower (e.g., 0.5A) | Moderate (e.g., 0.5-1A) |

| Isolation | Good (Physical gap) | Typically Opto-isolated | Typically Opto-isolated |

| Surge Tolerance | Better | Lower, requires protection | Lower, requires protection |

| External Power Req. | Load circuit needs own AC/DC power | Load circuit needs own DC power | Load circuit needs own AC power |

| Typical Application | Contactors, Solenoids, Lamps | High-Speed Pulse (Motion), SSRs, LEDs | AC Solenoids, Small AC Loads |

Selection Guidance:

- If the load is AC or DC, and switching frequency is low (e.g., less than 6 times per minute), Relay Output is often the preferred choice due to simplicity and cost-effectiveness.

- If high-speed switching, pulse output generation (for motion control), or frequent switching of DC loads is required, Transistor Output is necessary. Remember to select Sink (NPN) or Source (PNP) based on your system design and sensor types.

- If the load is AC and requires faster switching than relays or very frequent operation, Triac Output can be considered.

Conclusion:

The Programmable Logic Controller (PLC), with its inherent flexibility, powerful functionality, ease of programming and maintenance, and exceptional reliability, stands as an indispensable core component in the field of modern industrial automation control.

Its applications span from fundamental digital logic control to sophisticated motion control, precise analog regulation, advanced data processing, and seamless network communication, permeating automated production lines and equipment across diverse industries.

Understanding the fundamental concepts of PLCs, familiarizing oneself with their diverse capabilities, and mastering the correct input/output wiring techniques (particularly distinguishing between Sink/Source, NPN/PNP, and selecting the appropriate output type) are essential skills for every automation engineer and technician.

As Industry 4.0 and smart manufacturing continue to evolve, PLCs will maintain their critical role, empowering enterprises to achieve more efficient, intelligent, and flexible production.

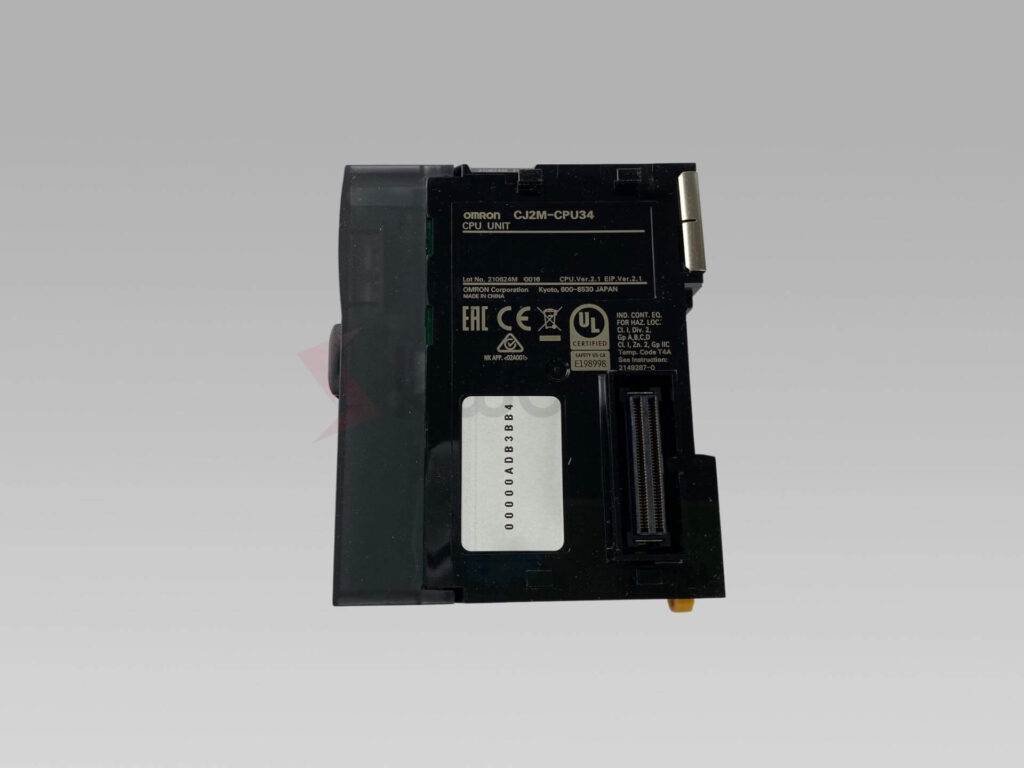

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

CNC Router vs Spindle: Which to Use?

This article dives deep into the crucial decision of choosing between a router and a spindle for your CNC machine. Whether you’re a seasoned manufacturer or new to CNC technology, understanding the differences between these two vital components is essential for optimizing your production processes. This comprehensive guide will compare spindles and routers, exploring their capabilities, advantages, and disadvantages to help you make an informed decision that aligns with your manufacturing needs and goals.

Kwoco’s Successful Collaboration with Global Trading Companies

Kwoco’s Successful Collaboration with Global Trading Companies In today’s global market, the reliability of the supply chain directly influences the

A Buying Guide for Mitsubishi PLCs

Are you feeling confused about choosing the right Mitsubishi PLC for your project? It’s normal to feel overwhelmed when faced with numerous models and specifications.