Why Should We Add a Brake Resistor to the Inverter?

- kwoco-plc.com

- August 30, 2024

- 12:30 am

Table of Contents

As an engineer, I know firsthand the importance of maintaining the stability and efficiency of your inverter system. Adding a brake resistor is crucial in certain scenarios to prevent damage to your equipment and ensure optimal performance.

In this blog post, I’ll dive into the technical aspects of brake resistors, why they’re needed, and how to choose the right one for your system.

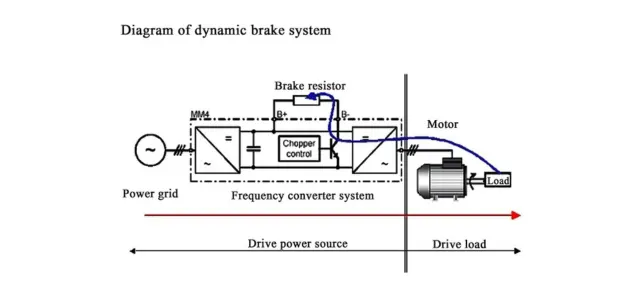

In simple terms, when your inverter is connected to a three-phase motor, there are situations where the motor’s momentum can work against you. For example, during frequent start-stop cycles or when dealing with heavy loads, the motor continues to spin due to inertia even after the inverter signals it to stop. At this point, the motor acts as a generator, sending current back into the inverter. This is where problems arise.

Without a brake resistor, this back-fed current can cause the inverter to malfunction, display error messages, or even suffer from severe damage. The brake resistor is essential because it dissipates this excess energy, preventing it from causing harm to your system.

When Does an Inverter Need a Brake Resistor?

You might be wondering, “Do I always need to add a brake resistor to my inverter?” The answer is not always. However, in scenarios where the load is heavy or where the start-stop cycles are frequent and rapid, a brake resistor becomes necessary. Here’s why.

Imagine you’re working with a large industrial machine that frequently stops and starts. Each time the machine stops, the motor’s inertia causes it to keep spinning momentarily, generating unwanted current. This current, if not properly managed, could cause your inverter to trip or, worse, get damaged. A brake resistor acts as a safeguard, dissipating this energy as heat, ensuring your inverter continues to function smoothly.

Why Is It Important to Add a Brake Resistor?

Now that we’ve established when you might need a brake resistor, let’s delve into why it’s so crucial. The primary reason for adding a brake resistor is to protect your inverter from the potentially damaging effects of regenerative energy. When the motor acts as a generator, the energy it produces can exceed the inverter’s capacity to handle it. This is where the brake resistor comes into play.

The brake resistor dissipates this energy, converting it into heat and releasing it safely, preventing any harmful effects on your inverter. Without this critical component, your inverter could experience overvoltage, overheating, or even catastrophic failure.

How to Determine the Right Size of a Brake Resistor?

Choosing the right brake resistor is essential for ensuring that your system operates effectively. The size of the brake resistor you need depends on the load and the specifications of your motor and inverter. Most inverter manuals provide detailed guidelines on selecting the appropriate brake resistor based on your specific setup.

For example, if you’re working with a large motor under heavy load, you’ll need a brake resistor capable of dissipating a significant amount of energy. Consulting the manual and understanding your system’s requirements will help you make the right choice.

What Happens If You Don't Use a Brake Resistor?

Skipping the brake resistor in situations where it’s needed can have severe consequences. In the best-case scenario, you might experience frequent tripping of the inverter, leading to downtime and reduced productivity. In the worst case, the inverter could be permanently damaged, leading to costly repairs or replacements.

To avoid these issues, it’s crucial to understand the specific needs of your system and ensure that a brake resistor is included where necessary. This small component can save you from significant headaches down the line.

Can a Brake Resistor Improve System Efficiency?

Interestingly, adding a brake resistor can also improve the overall efficiency of your system. By efficiently managing the energy generated during braking cycles, a brake resistor can help your system operate more smoothly, reducing wear and tear on your components.

This not only prolongs the life of your inverter but also enhances the performance of your entire setup.

Conclusion

In conclusion, adding a brake resistor to your inverter is not just a technical requirement; it’s a critical step in safeguarding your equipment and ensuring the longevity of your system. Whether you’re dealing with heavy loads or frequent start-stop cycles, a brake resistor is your best defense against potential inverter damage. Remember, always consult your inverter’s manual and consider the specific needs of your system when choosing the right brake resistor.

Kwoco provides brand new and original inverters of various brands, such as Mitsubishi, Omron, Schneider. If you are looking for an inverter supplier, please contact us ([email protected]).

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

Why Your PLC Needs a Separate Power Supply

Why Your PLC Needs a Separate Power Supply Have you ever wondered why PLC systems often require a separate power

Why Your Business Needs a Variable Frequency Drive

Why Your Business Needs a Variable Frequency Drive When managing industrial operations, optimizing energy efficiency while maintaining performance is crucial.

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.