What Are the 5 Most Common PLC Programming Languages?

- kwoco-plc.com

- August 28, 2024

- 8:53 pm

Problem-solving in industrial automation often hinges on one key factor: the ability to communicate with a Programmable Logic Controller (PLC). Whether you’re a seasoned engineer or just stepping into the world of automation, understanding PLC programming languages is crucial. But with so many options, where should you start?

Table of Contents

There are five commonly used PLC programming languages, namely Ladder Diagram (LD), Structured Text(ST), Sequential Function Chart(SFC), Function Block Diagram(FBD) and Instruction List(IL).

Each has its strengths, and knowing when to use which one can be the difference between a smooth operation and a costly mistake.

Automation is complex, but it doesn’t have to be intimidating. My goal is to demystify these programming languages so that you can choose the best fit for your next project.

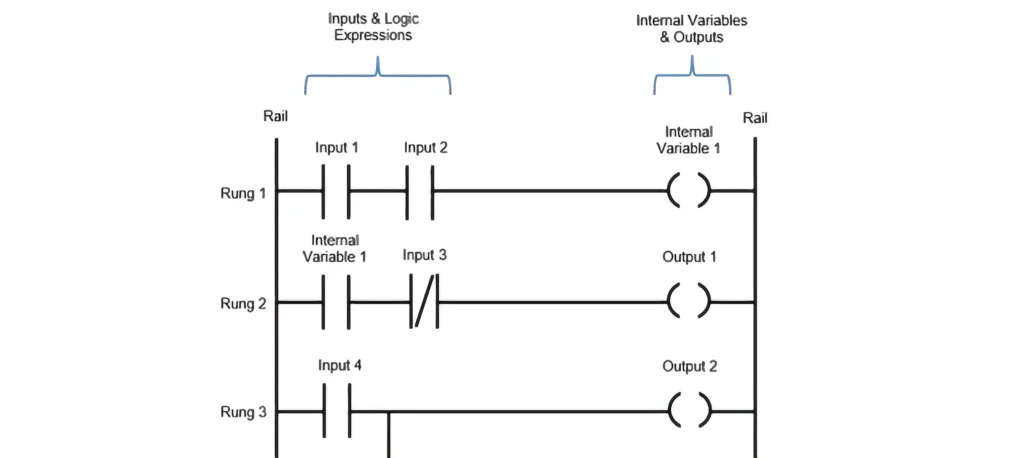

What Is Ladder Diagram and Why Is It So Popular?

Ladder Diagram (LD) is often the first PLC programming language engineers encounter. It’s a graphical language resembling electrical relay logic diagrams, making it intuitive for those with an electrical background. LD is widely used for its simplicity and ease of troubleshooting. However, it does have limitations when dealing with more complex operations.

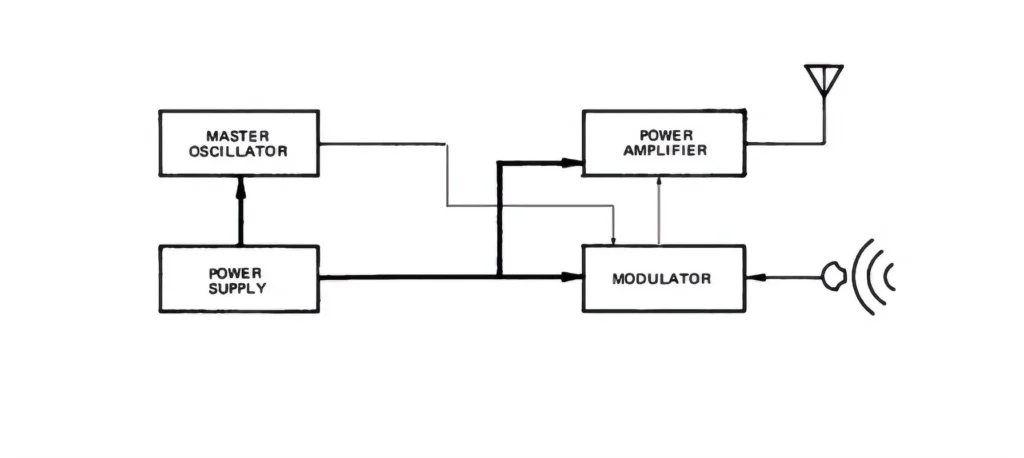

How Does Function Block Diagram Stand Out?

Function Block Diagram (FBD) is another graphical language, but instead of relays and switches, it uses blocks to represent functions. This makes FBD ideal for applications that require frequent and repetitive operations.

If you’re dealing with systems that need continuous control, FBD can be a lifesaver. Plus, it’s easier to reuse code across different projects, which can save time and reduce errors.

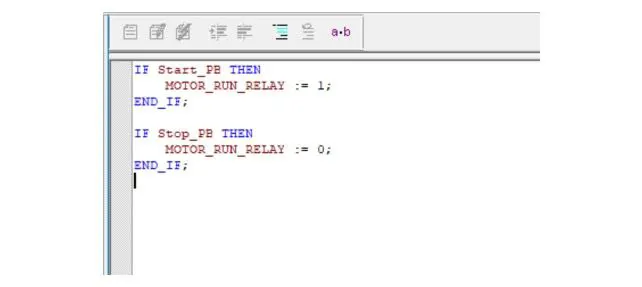

Why Is Structured Text So Powerful?

Structured Text (ST) is a high-level language resembling traditional programming languages like Python or C. It’s text-based and offers more flexibility for complex operations and data handling.

If your project involves advanced algorithms or data manipulation, ST could be your go-to.

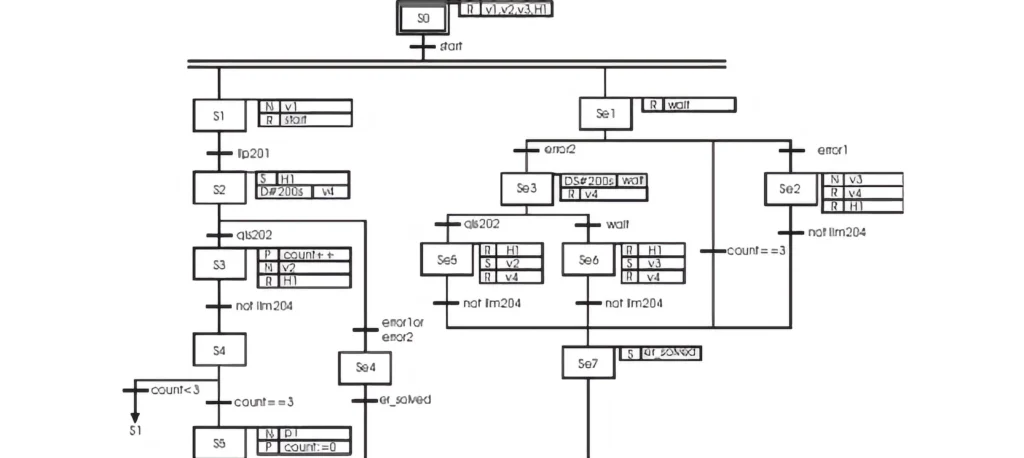

What Makes Sequential Function Charts Unique?

Sequential Function Charts (SFC) are excellent for processes that require a sequence of operations, such as batch processing or state machines. SFC breaks down the process into steps, transitions, and actions, providing a clear visual representation. It’s especially useful in industries where process control is critical.

Where Does Instruction List Fit In?

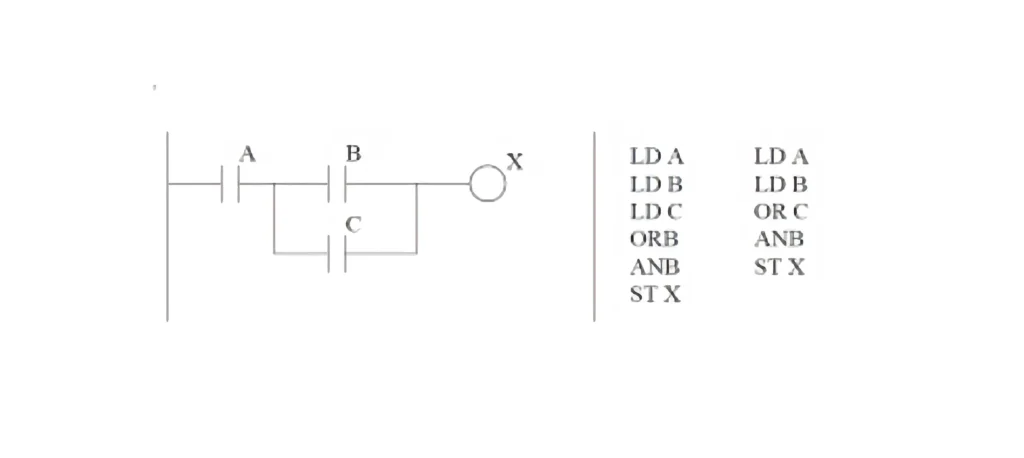

Instruction List (IL) is a low-level, text-based language. It’s akin to assembly language in traditional programming. While IL is not as user-friendly as the others, it offers unmatched control and efficiency for those who know how to wield it.

It’s best suited for simple tasks or when you need to squeeze every bit of performance from your PLC.

Which PLC Programming Language Is Best for Your Project?

That depends on your specific needs and the complexity of your system. Ladder Diagram is great for simple, discrete operations, while Structured Text shines in data-heavy environments. If you need modular, reusable code, Function Block Diagram is a strong contender, and for sequential operations, Sequential Function Charts are hard to beat. Instruction List remains a niche choice for those needing precision and performance.

Are you working on a project that requires real-time control? Or perhaps you’re dealing with a complex system that needs robust data handling?

More Related Questions

- What are the advantages of Ladder Diagram over Structured Text?

- How does Function Block Diagram improve code reusability?

- What industries benefit most from Sequential Function Charts?

- Can Instruction List programming be combined with other languages?

- What is the learning curve for each PLC programming language?

Kwoco offers brand-new, original Omron PLCs at competitive prices.

Conclusion

Choosing the right PLC programming language is critical to the success of your automation project. Each language has its strengths, and understanding these will help you select the best tool for the job. Remember, the right language can not only simplify your programming tasks but also enhance the efficiency and reliability of your systems.

Looking for brand new, original Omron, Mitsubishi, Schneider PLCs in stock? Contact Kwoco now for free consultation and immediate shipping. We’re here to support your automation needs!

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

Why Your PLC Needs a Separate Power Supply

Why Your PLC Needs a Separate Power Supply Have you ever wondered why PLC systems often require a separate power

Why Your Business Needs a Variable Frequency Drive

Why Your Business Needs a Variable Frequency Drive When managing industrial operations, optimizing energy efficiency while maintaining performance is crucial.

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.