What is a PLC and What Does It Do?

- kwoco-plc.com

- September 18, 2024

- 3:58 am

In today’s fast-paced industrial world, companies need smart, reliable, and efficient control systems to manage their processes. If you’ve been involved in manufacturing, automation, or any kind of engineering, you’ve probably heard about PLCs. But what does PLC stand for, and what does it actually do?

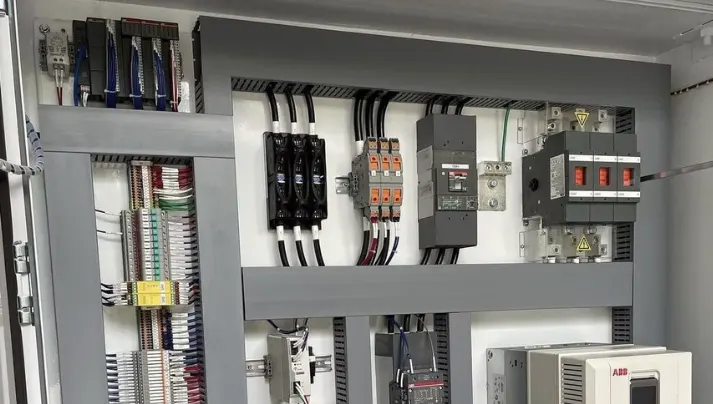

PLC stands for Programmable Logic Controller. It’s a ruggedized computer used for automating industrial processes. Whether you’re dealing with assembly lines, robotics, or factory machinery, a PLC helps control it all efficiently and reliably. It’s designed to withstand harsh environments like dust, moisture, extreme temperatures, and electrical noise, which are common in industrial settings.

Table of Contents

Unlike traditional control systems, PLCs offer flexibility. They can be reprogrammed or adjusted quickly without needing to overhaul an entire system.

That’s why they are a go-to solution for industries looking to optimize their production lines. But there’s more to the story—PLC’s capabilities stretch beyond just control.

How Does a PLC Work?

At its core, a PLC works by taking inputs from sensors and other devices, processing them based on a program, and then providing outputs to control other machinery.

Imagine a system that reads the temperature of an industrial oven, processes that data, and then adjusts the heat automatically based on preset conditions. That’s the magic of a PLC in action.

Here’s a quick rundown of the key components:

- Inputs: Devices like sensors that provide real-time data (temperature, pressure, flow rates, etc.)

- CPU (Central Processing Unit): The brain of the PLC that processes inputs based on a pre-written program.

- Outputs: Devices that respond to the CPU’s commands, like motors, relays, or actuators, to control equipment.

When we install PLCs in industrial setups, they monitor and control processes in real-time. PLCs ensure that machines run efficiently, reduce waste, and improve safety.

Thanks to their ability to make split-second decisions, they can handle everything from simple tasks like turning a motor on or off to more complex operations involving multiple systems working in harmony.

What Industries Use PLCs?

Have you ever wondered how huge assembly lines work seamlessly? That’s thanks to PLCs. They are used across a wide range of industries:

- Manufacturing: PLCs control assembly lines, packaging processes, and robotic arms.

- Automotive: Car production lines heavily rely on PLCs to automate repetitive tasks.

- Food and Beverage: Ensuring quality and consistency by managing conveyor belts, mixing processes, and packaging systems.

- Pharmaceuticals: Used for everything from packaging to complex chemical processing.

- Energy: PLCs control power generation, distribution, and even renewable energy processes.

The versatility of PLCs allows them to be adapted to a wide range of tasks, from controlling simple machines to managing entire factories. Their reliability and flexibility make them indispensable in today’s automation-driven world.

Why Choose PLC Over Other Control Systems?

- Reliability: They are designed to operate in industrial environments where other systems might fail. Dust, temperature fluctuations, or electrical noise are no match for a well-built PLC.

- Ease of Programming: Engineers like me love PLCs because they can be programmed using ladder logic, a simple and intuitive language that mirrors electrical relay systems. It allows quick adaptation and troubleshooting.

- Flexibility: If you need to add a new machine to your line or adjust a process, a PLC can be easily reprogrammed to handle it, saving you time and money.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

How Does Kwoco Help with PLCs?

As an engineer at Kwoco, I’ve seen how PLCs can revolutionize industrial processes. We stock a wide range of PLCs, from compact units for small systems to advanced models for large-scale operations. We offer not just the products, but also technical support to ensure your system runs smoothly.

Our team works closely with engineers, purchasing managers, and business owners to provide the right solutions for their needs. Whether it’s programming, troubleshooting, or selecting the right PLC for your system, we’re here to help.

Can PLCs Save My Company Money?

You bet. One of the greatest benefits of using PLCs is their ability to reduce downtime and improve efficiency. Since they can be easily reprogrammed, companies can avoid costly delays when changes in the production process are needed. Plus, by automating more tasks, businesses can reduce the need for manual labor, which means lower operational costs in the long run.

Additionally, PLCs help optimize processes, leading to less waste and more consistent product quality. In industries like food and beverage or pharmaceuticals, this is especially critical for maintaining standards.

Conclusion

In short, a PLC is the cornerstone of modern industrial automation. It allows companies to streamline their processes, reduce costs, and improve product quality. Whether you’re running a factory, managing a production line, or dealing with energy distribution, a PLC can handle it all.

At Kwoco, we specialize in providing high-quality PLCs from brands like Omron, Mitsubishi, and Schneider. Our team is ready to support your industrial needs, ensuring you get the best automation solutions for your business. If you want to know more about how PLCs can fit into your system, feel free to reach out!

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

Why Your PLC Needs a Separate Power Supply

Why Your PLC Needs a Separate Power Supply Have you ever wondered why PLC systems often require a separate power

Why Your Business Needs a Variable Frequency Drive

Why Your Business Needs a Variable Frequency Drive When managing industrial operations, optimizing energy efficiency while maintaining performance is crucial.

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.