The Core Engine of Industrial Automation: A Comprehensive Guide to PLC Principles, Classification, and Selection

Table of Contents

This write-up supplies an engineering-level deep study the core design of PLCs, their 3 main categories (Integrated, Modular, and Stackable), and their extensive applications in discrete logic and motion control. By evaluating technological specifications and market fads, this overview works as a reliable referral for PLC equipment option and system assimilation.

I. Defining the PLC

A PLC (Programmable Logic Controller) is a digital computing electronic system specifically engineered for operation within industrial environments. If commercial robotics stand for the ” arm or legs ” of a system, the PLC works as the ” central nervous system ” that manages the whole procedure.

1.1 Core Architecture

The design logic of a PLC mirrors human physiological functions, ensuring high-performance execution in demanding environments:

Microprocessor (CPU): The “brain” in charge of reasoning procedures, instruction decoding, and job organizing.

Memory (ROM/RAM): The “memory system” that stores system firmware, user-defined logic (application programs), and runtime data.

Input/Output Systems (I/O): The ” sensory and electric motor ” interface. Input units interface with field sensors (e.g., photoelectric sensing units, pressure transmitters), while Output units drive actuators (e.g., solenoid shutoffs, contactors).

Power Supply & Programs Terminal: Offers supported power to the backplane and assists in Human-Machine Communication (HMI) for arrangement and troubleshooting.

1.2 Why PLCs Dominate Industrial Control

Contrasted to legacy hard-wired relay control systems, PLCs provide a number of important benefits:

High Dependability: Developed with Large Scale Integration (LSI) circuits, including durable electromagnetic compatibility (EMC) and anti-interference abilities.

Flexibility: Reasoning reconfiguration is attained using software application alteration as opposed to equipment rewiring.

Simplicity of Usage: Makes use of standard shows languages, such as Ladder Diagram (LD) , which lines up with design reasoning.

Environmental Toughness: Engineered to run dependably under severe temperature level, resonance, and electro-magnetic sound licensed under IEC 61131 criteria.

II. PLC Classifications: Scaling for System Requirements

PLC hardware is categorized into three main types based upon structural design. Comprehending these distinctions is crucial for enhanced system architecture.

1. Integrated PLC (Compact PLC)

An Integrated PLC houses the CPU, I/O interfaces, memory, and power supply within a single chassis.

Qualities: Compact impact, cost-effective, but with a fixed I/O count.

Applications: Small-scale, standalone OEM machinery such as packaging machines and injection molding machines.

2. Modular PLC

Additionally called Rack-mounted PLC, this kind enables the setting up of CPU components, I/O components, and interaction components onto a typical backplane or bus.

Qualities: Extremely scalable, very easy to preserve, and designed for complex systems.

Applications: Large manufacturing facility automation lines, such as automobile setting up and chemical procedure control. The Siemens SIMATIC S7-1500 series is a prime example.

3. Stackable PLC

A hybrid design where the CPU unit is independent, and expansion units are added via ribbon cables or direct-plug interfaces.

Qualities: Combines a compact form factor with a degree of configuration flexibility.

Table 1: Technical Contrast of PLC Frameworks .

| Parameter | Integrated PLC | Modular PLC | Stackable PLC |

|---|---|---|---|

| Footprint Compactness | Extremely High | Lower (Requires rack space) | High |

| I/O Scalability | Limited (Fixed points) | Extensive (Backplane expansion) | Moderate |

| Maintenance Efficiency | Total unit replacement | Module-level replacement | Unit-level replacement |

| Capital Expenditure | Low | High (Initial investment) | Medium |

| Typical I/O Range | 10 – 64 points | 256+ points | 64 – 256 points |

III. 5 Significant Application Domains

Modern PLCs have actually progressed past straightforward “on/off ” controllers right into multi-functional systems incorporating calculation, interaction, and high-speed movement control.

Discrete Reasoning Control: This is the most basic application of a PLC. It replaces traditional relay logic and is widely used in printing presses, packaging lines, electroplating lines, etc.

Motion Control: Utilizing high-speed pulse outputs or industrial fieldbuses (e.g., EtherCAT) for precision positioning of servo and stepper motors. Essential for CNC machinery and industrial robotics.

Process Control: Leveraging PID formulas to deal with analog signals (temperature level, stress, circulation). Essential in metallurgy, central heating boiler control, and petrochemical markets .

Data Processing & Analytics: Modern PLCs have effective mathematical capacities, interfacing with ERP/MES systems for information procurement, arranging, and coverage.

Industrial Communication/Networking: Supporting protocols such as PROFINET, Modbus TCP, and EtherNet/IP to assist in connection in between PLCs, HMIs, and the Cloud.

IV. Market Fads: The Digital Change of PLCs

Market information suggests that the worldwide need for PLCs is growing at a CAGR of approximately 5% -7%.

Table 2: 2023-2025 PLC Market Technology Trend Forecast

| Trend Direction | Market Share Preference (Forecast) | Key Drivers |

|---|---|---|

| All-in-One Integration | 40% | Demand for space/cost optimization in compact machinery. |

| Edge Computing/Cloud Connectivity | 25% | Data acquisition requirements for IIoT (Industrial IoT). |

| High-Performance Motion Control | 20% | Precision requirements in EV battery and semiconductor industries. |

| Open Platforms/Ease of Programming | 15% | Reduction of engineering hours; alignment with open standards championed by Rockwell Automation. |

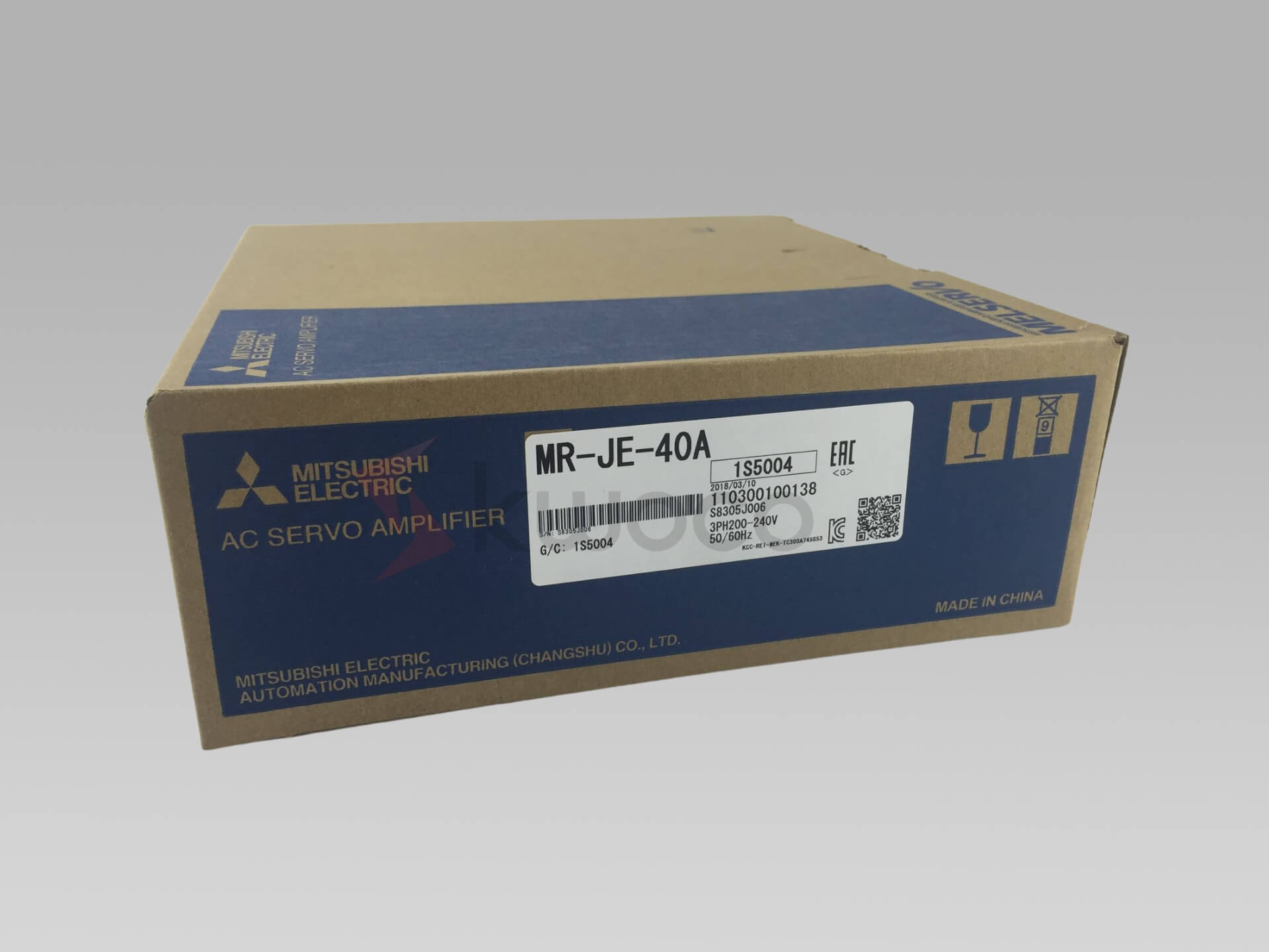

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

The selection of a PLC directly impacts the stability and efficiency of the production line.

If you prioritize cost-effectiveness and space efficiency: integrated or stackable PLCs are the preferred choice for small and medium-sized projects (such as single machines).

If you prioritize system scalability and future-proofing: modular, combined PLCs with powerful communication capabilities (such as those supporting Profinet or EtherNet/IP protocols) are better suited to meet the upgrade needs of future digital workshops.

When choosing PLC automation products, it’s crucial to consider not only the hardware parameters but also the underlying software ecosystem and technical support. With the introduction of AI and edge computing, future PLCs will become more intelligent, evolving from “executing instructions” to “autonomous decision-making.”

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Top Six Omron PLC Suppliers in Italy

Top Six Omron PLC Suppliers in Italy As someone deeply involved in the industrial automation sector, particularly in international trade

Comprehensive Controllogix 5580 Selection Guide for PLCs

Selecting the right Programmable Logic Controller (PLC) is crucial for optimizing your industrial automation processes. This guide delves into the ControlLogix 5580 controllers, helping you make an informed decision for your control system needs.

France Omron PLC Supplier Near You

In the field of industrial automation, integrity and effectiveness are the foundations of success. As the core of complex systems, the PLC (Programmable Logic Controller) from Omron is definitely a benchmark brand name in the industry.