The Basic Distinction Between Large-Scale and Mid-Range PLCs

Table of Contents

This short article reviews both historical PLC systems and contemporary product growth, discussing why redundancy has come to be the genuine separating line and what it means for industrial automation.

Why I/O Point Count Is No Longer a Reliable Definition

Traditionally, 256– 2048 I/O points defined a mid-range PLC, while above 2048 points specified a large-scale PLC. This classification made good sense in the early years, when PLC efficiency was limited.

However, with advancements in semiconductor modern technology and CPU handling power, many mid-range PLCs can now easily handle I/O beyond these thresholds.

The problem is: point count alone cannot guarantee reliability in mission-critical applications. Modern production lines, energy management systems, and transport hubs need PLCs that not only procedure a lot more data yet also ensure uninterrupted procedure even under fault conditions.

This is precisely why redundancy modern technology has become real criteria for large-scale PLCs.

Redundancy Technology: The Actual Barrier to Large-Scale PLCs

Redundancy technology refers to dual-controller hot standby and seamless switchover mechanisms across CPU, communication, and even power modules.

When the primary controller fails, the backup can take over within milliseconds, ensuring continuous system operation.

The value of redundancy layout hinges on:

Enhanced reliability : Vital for industries such as power generation, petrochemicals, and rail transportation where downtime is unacceptable.

Improved safety : Stops financial loss and security risks brought on by disturbances.

Long-lasting stability : Ensures continuous and reliable operation over lengthy solution cycles.

As a result, it is reasonable to conclude: redundancy technology is truth threshold that specifies a large-scale PLC .

Classic PLC Cases in History

To better illustrate this point, allow’s take another look at several landmark PLC systems when considered industry legends:

1. Allen-Bradley PLC-5 System

Despite its minimal memory, its modular layout and redundancy assistance made it a top choice for petrochemical and power sectors.

2. Modicon 984 System

A milestone product that presented flexible network communication and developments in redundancy style.

3. Siemens S5 System

Though surpassed by today’s mid-range PLCs in I/O capacity, its redundancy and expandability kept it in service throughout essential industries for years.

These instances prove one fact: I/O count has actually never ever specified massive PLCs– dependability has actually constantly been the core.

Contrast: Mid-Range PLC vs. Large-Scale PLC

| Feature | Mid-Range PLC | Large-Scale PLC |

|---|---|---|

| I/O Capacity | 256 – 2048 | 2048+ |

| Core Processing | High-speed, suitable for most mid-size factories | Handles complex tasks, designed for large projects |

| Redundancy | Limited redundancy in select models | Standard redundancy (CPU, power, communication) |

| Application | General manufacturing, machinery control | Power plants, petrochemicals, transportation hubs, integrated plant systems |

| System Reliability | Higher downtime risk | 24/7 continuous operation with minimal downtime risk |

From this contrast, it is clear that redundancy is the specifying element — which is why many industries prefer to invest in large-scale PLCs despite higher costs.

Significance for Industrial Automation

With the advancement of Sector 4.0 and smart manufacturing, PLC systems need to not only sustain greater I/O counts but likewise stay stable in scenarios including large data acquisition, cloud integration, and edge computing.

Large PLC redundancy is especially essential in:

Energy : Nuclear power plant can not pay for downtime– repetitive PLCs are required.

Transportation : Metro and high-speed rail signaling should remain continual for security.

Petrochemicals : Refining operations run continually; also a short shutdown can indicate multi-million-dollar losses.

External Data and Industry Overview

According to MarketsandMarkets, the international PLC market is forecasted to reach USD 15.7 billion by 2027 , with boosting need for high-reliability and redundant PLC systems.

This confirms the point: the future competitiveness of large PLCs lies in integrity and redundancy– not simply in I/O expansion.

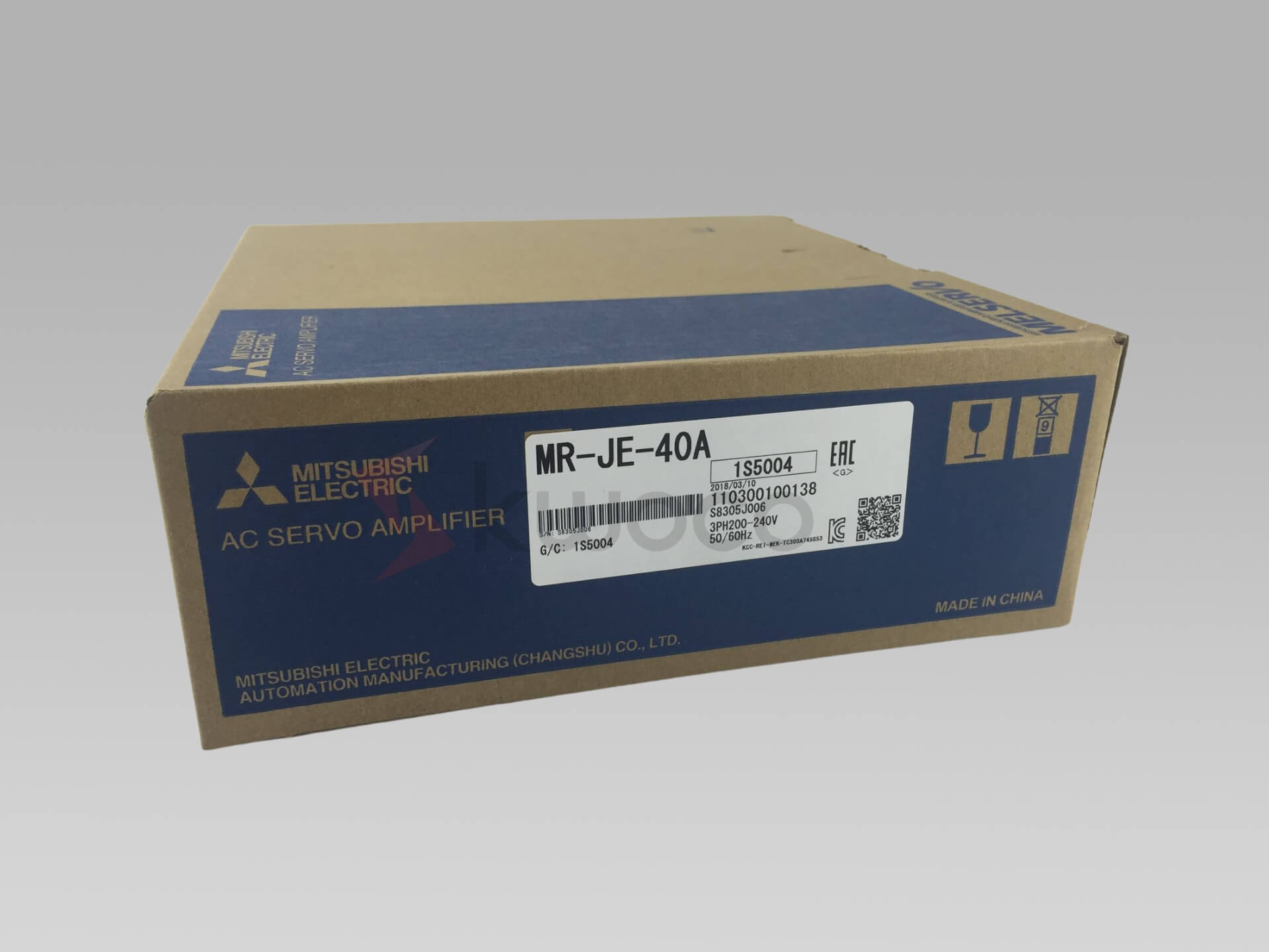

Power your projects with brand-new, original Omron, Mitsubishi, Schneider PLC – in stock, ready now!

Conclusion

The boundary in between mid-range and large PLCs may appear to be I/O capacity. In reality, the decisive difference hinges on redundancy technology and reliability design.

From historical PLC milestones to existing market trends, the proof continually reveals: large-scale PLCs represent not just dimension, but the uncompromising demand of important markets for continual procedure and safety and security .

For business, understanding this distinction is vital to making the right choices when picking automation systems.

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Top 6 HMI Manufacturers in Industrial Automation

Top 6 HMI Manufacturers in Industrial Automation As an engineer at Kwoco with years of experience in the industrial automation

Kwoco’s Successful Collaboration with Global Trading Companies

Kwoco’s Successful Collaboration with Global Trading Companies In today’s global market, the reliability of the supply chain directly influences the

The 7 Most Popular PLC Brands

The 7 Most Popular PLC Brands Choosing the right PLC brand among the many options available can be overwhelming. Don’t