What Are the Characteristics of the Five Major PLC Programming Languages?

- kwoco-plc.com

- September 23, 2024

- 1:32 am

In the world of industrial automation, choosing the right PLC programming language can make a big difference in efficiency, performance, and ease of use. Each of the five major languages has its strengths and is suited to different tasks. So, which one is right for your needs?

Let’s explore the characteristics of these languages to help you make the best choice. Whether you’re a beginner or a seasoned engineer, understanding these differences will save you time and effort on your next project.

Table of Contents

Why Choose Ladder Diagram (LD)?

Ladder Diagram is often the go-to for many PLC users, especially those with a background in electrical engineering. It’s intuitive, visually straightforward, and grounded in relay logic, making it the most accessible of the PLC languages.

Advantages:

- Easy to learn and understand.

- Originates from relay logic, making it intuitive for electrical professionals.

- Simplified symbols make it easy to grasp for those new to PLCs.

But it’s not just about ease of use; it’s also about getting things done efficiently. If you’re looking to quickly implement control logic without diving into complex code, LD might just be your best friend.

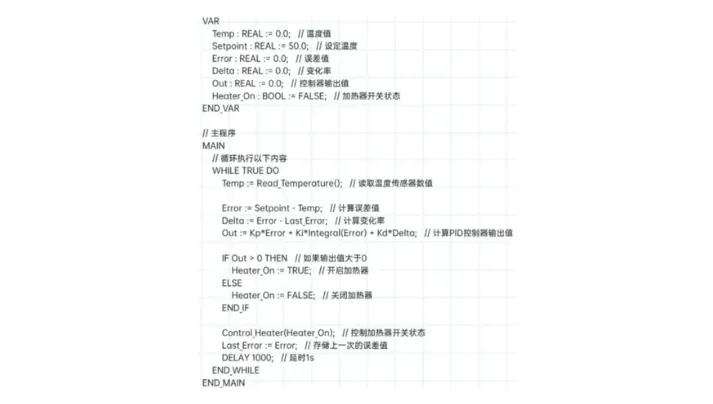

What Makes Structured Text (ST) Stand Out?

Structured Text is like the high-level language of PLC programming—fast, standardized, and great for complex tasks. It’s particularly suited for math-heavy operations and motion control, where LD might fall short.

- Advantages:

- High speed and portability.

- Structured Text Language is a programming language similar to a high-level language

- Ideal for medium to large-scale PLC systems, effectively describing variable relationships.

- Characteristics:

- Requires advanced programming skills, particularly knowledge of high-level computer languages.

- Less intuitive than LD, but it shines where other languages struggle.

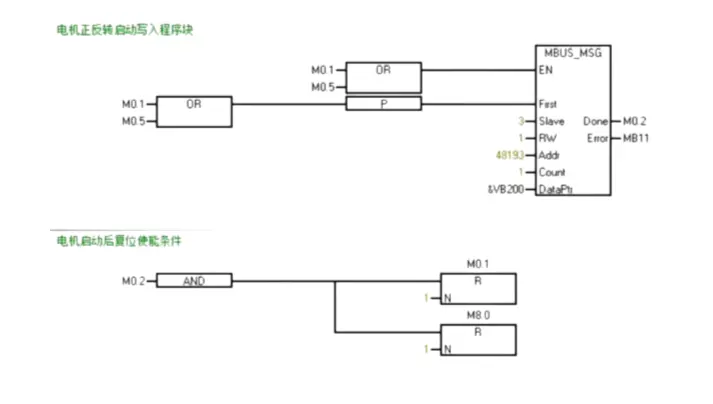

Why Use Function Block Diagram (FBD)?

If you’re a fan of modular, clear, and easy-to-debug code, Function Block Diagram might be the language for you. FBD visually resembles digital circuits, which is perfect for those familiar with logic gates and circuit design.

- Advantages:

- Supports modular design with clear logic structures.

- Easy to grasp for anyone with a digital circuit background.

- Characteristics:

- Breaks down tasks into functional modules, making it easy to understand control plans.

- Uses graphical elements for enhanced intuitiveness and usability.

- Reduces programming, configuration, and debugging time due to its clear functional relationships.

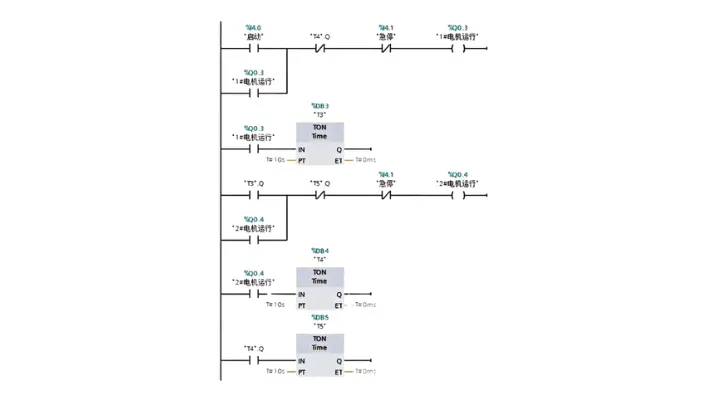

When to Use Sequential Function Chart (SFC)?

Sequential Function Chart excels in scenarios where process sequencing and flow control are key. It uses a graphical format to represent parallel and complex systems, ideal for sequential logic control.

- Advantages:

- Perfect for sequential logic control, with a visual flowchart approach.

- Clear graphical descriptions of parallel and complex systems, supporting model-based programming.

- Characteristics:

- Organizes tasks according to functional flow sequences.

- Ideal for large-scale programs, allowing for collaborative design and flexible structure, saving time in design and debugging.

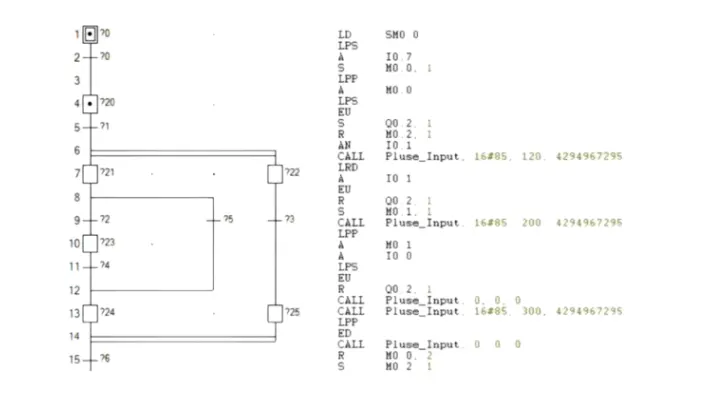

Instruction List (IL): Is It for You?

- Advantages:

- Close to the hardware, delivering precise, high-efficiency operations.

- Resembles assembly language, built with opcodes and operands.

- Characteristics:

- Uses mnemonics to represent operations, making it easier to memorize and use.

- Can be converted with LD in many PLC software, adding flexibility in programming environments.

- Suitable for handheld programming devices, making it accessible even without computers.

Which PLC Language Should You Choose?

- What’s your current project complexity?

- How familiar are you with high-level programming languages?

- Do you need a visual representation or prefer text-based coding?

- Are you working on sequential processes or motion control?

- Do you need hardware-level precision in your operations?

These questions will guide you toward the right choice. Each language has its unique strengths, and your project needs will determine which one to pick.

Conclusion

Where to Buy New Original PLC?

Looking for new, original PLCs for your projects? At Kwoco, we stock the latest PLCs from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Contact Now([email protected]).

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

Why Your PLC Needs a Separate Power Supply

Why Your PLC Needs a Separate Power Supply Have you ever wondered why PLC systems often require a separate power

Why Your Business Needs a Variable Frequency Drive

Why Your Business Needs a Variable Frequency Drive When managing industrial operations, optimizing energy efficiency while maintaining performance is crucial.

Why Signal Isolation is Crucial for Omron PLCs?

Why Signal Isolation is Crucial for Omron PLCs? In the world of industrial automation, signal interference is a silent killer.