Cómo dominar el modo de funcionamiento de un temporizador: una guía completa

Tabla de contenido

1. ¿Qué es un temporizador y cómo funciona?

Un temporizador es un tipo de reloj especializado que se utiliza para medir intervalos de tiempo. Los temporizadores son dispositivos que controlan un circuito eléctrico en función de un tiempo establecido. Estos dispositivos son fundamentales en la automatización industrial y permiten un control preciso de diversos procesos.

Los temporizadores son esenciales para controlar la iluminación y gestionar maquinaria compleja. El funcionamiento de un temporizador suele implicar la configuración de un intervalo de tiempo deseado después del cual el interruptor cambia de estado (encendido o apagado).

Cuando se aplica un voltaje a la sección de suministro de energía del temporizador, este comienza a funcionar. Cuenta los ciclos de reloj o mide el tiempo hasta que se alcanza un valor preestablecido. Por ejemplo, un temporizador simple podría encender un dispositivo durante un intervalo de tiempo específico y luego apagarlo.

En términos de ingeniería eléctrica, un temporizador es un componente que ayuda a gestionar y controlar operaciones basadas en el tiempo en circuitos y sistemas. El circuito temporizador se pone en marcha cuando se recibe la señal de entrada.

2. ¿Cuáles son los diferentes tipos de temporizadores disponibles?

Existen varios tipos de temporizadores disponibles, que se clasifican en general en temporizadores analógicos y temporizadores digitales. Los temporizadores analógicos suelen utilizar una perilla o dial para configurar el tiempo y suelen tener un diseño más simple.

Son fiables y sencillos para las necesidades básicas de cronometraje. El modo de funcionamiento es muy fácil de entender.

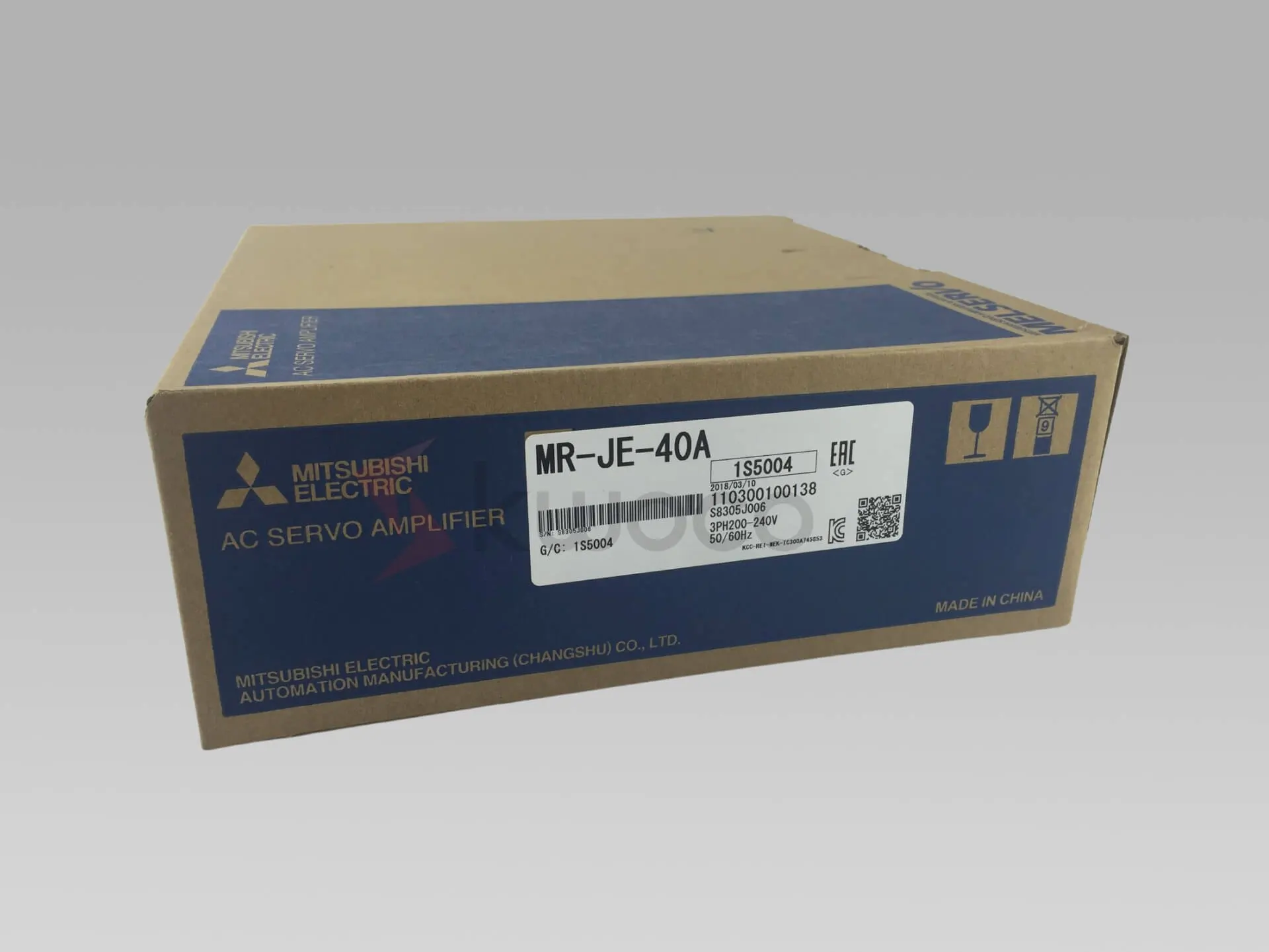

Por otro lado, los temporizadores digitales ofrecen más precisión y flexibilidad. Se pueden programar para diversas funciones, incluidas operaciones de retardo de encendido, intervalos y ciclos de repetición. En este caso, el PLC de Mitsubishi es una buena opción.

Por ejemplo, en una fábrica de maquinaria y equipos, se pueden utilizar temporizadores digitales para automatizar secuencias complejas, mejorando la eficiencia y la productividad. Estos temporizadores también se denominan a menudo contadores.

3. ¿Qué significa el modo de funcionamiento de un temporizador?

El modo de funcionamiento de un temporizador se refiere a la forma específica en que funciona el temporizador para controlar un circuito. Los modos de funcionamiento más comunes incluyen retardo de encendido, intervalo y retardo de apagado. Comprender estos modos es fundamental para seleccionar el tipo de temporizador adecuado para su aplicación.

En el funcionamiento con retardo de encendido, el temporizador demora el encendido de un dispositivo después de recibir una señal de entrada. El tiempo establecido determina la duración del retraso. El funcionamiento a intervalos implica encender un dispositivo durante un intervalo de tiempo específico y luego apagarlo.

La operación de apagado retardado hace lo contrario, apagando un dispositivo después de un retraso de tiempo establecido. Elegir el modo de operación correcto garantiza que su maquinaria y equipo funcionen como está previsto, optimizando el proceso de producción. Existen muchas aplicaciones de los temporizadores.

4. ¿Cómo se utilizan los temporizadores en la automatización industrial?

Los temporizadores desempeñan un papel fundamental en la automatización industrial. Se utilizan para controlar una amplia gama de dispositivos y procesos, desde tareas sencillas como encender luces hasta operaciones complejas en plantas de fabricación. El temporizador tiene diversas aplicaciones.

Los temporizadores se utilizan para diversos tipos de operaciones. Se deben conocer las aplicaciones y características de los temporizadores. Los temporizadores se utilizan para mantener un registro de los eventos externos que ocurren.

En un entorno industrial, los temporizadores pueden automatizar los tiempos de arranque y parada de la maquinaria, garantizando que el equipo funcione solo cuando sea necesario. Esto no solo ahorra energía, sino que también reduce el desgaste de la maquinaria.

Además, los temporizadores se pueden integrar en sistemas de seguridad, como el apagado automático de equipos si se detecta una falla. En ingeniería eléctrica, los temporizadores y los temporizadores digitales son componentes cruciales en el diseño de circuitos. Se utilizan ampliamente en la vida diaria y en dispositivos prácticos.

5. ¿Cómo funciona la operación de retardo de encendido en los temporizadores?

La operación con retardo de encendido, también conocida como operación con retardo de encendido de potencia o operación con retardo de encendido de señal, es una función fundamental en muchos temporizadores. Cuando se aplica un voltaje al temporizador, este espera a que transcurra el tiempo establecido antes de activar la salida. El temporizador cuenta hasta que alcanza el tiempo preestablecido.

Por ejemplo, en un proceso de fabricación, se puede utilizar un temporizador de retardo de encendido para garantizar que una cinta transportadora comience a moverse solo después de que todos los demás equipos estén listos. Esta sincronización es crucial para un funcionamiento fluido y eficiente.

Comprender la función de retardo de encendido es esencial para configurar correctamente el temporizador y lograr los resultados deseados en los procesos industriales. Es esencial contar con un retardo de tiempo preestablecido. El temporizador se inicia cuando se suministra voltaje.

6. ¿Cuál es la importancia de la función de intervalo en los temporizadores?

La función de intervalo de los temporizadores se utiliza para encender un dispositivo durante un intervalo de tiempo específico y luego apagarlo. Esta función es particularmente útil en aplicaciones en las que un dispositivo necesita funcionar de manera intermitente.

Por ejemplo, en un sistema de riego, se puede utilizar un temporizador de intervalos para regar las plantas durante un tiempo determinado a intervalos regulares. En un entorno de fabricación, esta función puede controlar procesos que requieren una activación periódica, como la aplicación de un revestimiento o la ejecución de un ciclo de prueba. La función de intervalos añade versatilidad al temporizador, lo que permite escenarios de control más complejos.

7. ¿Cómo pueden los temporizadores digitales beneficiar mi proceso de fabricación?

Los temporizadores digitales ofrecen numerosas ventajas para los procesos de fabricación. Proporcionan un control preciso de la temporización, lo que permite una automatización precisa de diversas tareas.

Con características como tiempo programable y múltiples modos de funcionamiento, los temporizadores digitales pueden manejar secuencias complejas y mejorar la eficiencia general.

En nuestra experiencia en automatización industrial, los temporizadores digitales han sido fundamentales para optimizar las operaciones. Por ejemplo, el uso de un temporizador digital para controlar el tiempo de curado de un producto puede garantizar una calidad constante y reducir los desechos.

Además, los temporizadores digitales se pueden integrar fácilmente en sistemas de control más grandes, como los que utilizan PLC Omron o Proface HMI, que ofrece una solución de automatización integral. Puede encontrar más información sobre Proface HMI en enlaceLos temporizadores también se denominan contadores.

8. ¿Cómo elegir el temporizador adecuado para su aplicación?

La elección del tipo correcto de temporizador depende de las necesidades específicas de su aplicación. Tenga en cuenta factores como el modo de funcionamiento requerido (retardo de encendido, intervalo, etc.), la precisión necesaria y el entorno en el que funcionará el temporizador. Los temporizadores se utilizan para medir intervalos de tiempo específicos.

Para aplicaciones básicas, un temporizador analógico puede ser suficiente. Sin embargo, para procesos más complejos, un temporizador digital con funciones avanzadas suele ser la mejor opción.

Evalúe los requisitos de voltaje y asegúrese de que el temporizador pueda soportar la carga eléctrica de su equipo. Consultar con expertos como nosotros puede ayudarlo a tomar una decisión informada y seleccionar el temporizador que mejor se adapte a sus necesidades. Para obtener más detalles, Contáctenos.

9. ¿Cuáles son algunas características avanzadas de los temporizadores modernos?

Los temporizadores modernos, especialmente los digitales, cuentan con una variedad de funciones avanzadas, como múltiples rangos de tiempo, configuraciones programables y la capacidad de interactuar con otros dispositivos. Algunos temporizadores ofrecen funciones como salida de pulsos, que se puede utilizar para generar velocidades en baudios para sistemas de comunicación.

También se pueden utilizar temporizadores avanzados en un sistema integrado para proporcionar funciones de control sofisticadas. Por ejemplo, se puede programar un temporizador para que active una interrupción cuando se cumpla una determinada condición, lo que permite un control y una supervisión en tiempo real.

Estas funciones mejoran las capacidades de sus sistemas de automatización, haciéndolos más flexibles y receptivos. El temporizador está configurado para iniciarse.

10. ¿Por qué son esenciales los interruptores temporizadores en los sistemas integrados?

En los sistemas integrados, los temporizadores son fundamentales para gestionar y controlar diversas operaciones. Un sistema integrado suele requerir una temporización precisa para tareas como la adquisición de datos, el procesamiento de señales y las funciones de control. También se generan con la ayuda de temporizadores.

Los temporizadores en sistemas integrados se pueden utilizar para generar señales de reloj, medir la duración de eventos y sincronizar diferentes partes del sistema.

Por ejemplo, en un sistema basado en microcontroladores, se puede utilizar un temporizador para controlar el ciclo de trabajo de una señal PWM o para programar tareas periódicas. Comprender la función de los temporizadores en los sistemas integrados es esencial para diseñar e implementar soluciones de control eficaces.

Preguntas frecuentes

Los temporizadores analógicos utilizan medios mecánicos o electrónicos simples para configurar el tiempo, generalmente con una perilla o dial. Son sencillos y confiables para las necesidades básicas de cronometraje. Los temporizadores digitales, por otro lado, utilizan circuitos y pantallas digitales, lo que ofrece mayor precisión, múltiples funciones (como retardo de encendido, intervalo, ciclo de repetición) y programabilidad. Son más versátiles para aplicaciones complejas.

Un temporizador con retardo de encendido comienza a contar el tiempo cuando se aplica un voltaje o se recibe una señal de entrada. Una vez transcurrido el tiempo preestablecido, el temporizador activa su salida, como encender un dispositivo. Este retraso garantiza que el dispositivo comience a funcionar solo después de una duración específica, lo que resulta útil para sincronizar operaciones en una secuencia.

Sí, los temporizadores se pueden utilizar en aplicaciones de seguridad. Por ejemplo, pueden apagar automáticamente la maquinaria si se detecta una falla o después de un cierto período de inactividad. Esto ayuda a prevenir accidentes y garantiza que el equipo funcione de manera segura.

La función de intervalo permite que un temporizador encienda un dispositivo durante un intervalo de tiempo específico y luego lo apague. Este modo es útil para operaciones que deben realizarse de manera intermitente, como hacer funcionar un motor durante una duración determinada a intervalos regulares. Ayuda a automatizar procesos que requieren una activación periódica.

La elección del modo de funcionamiento adecuado depende de las necesidades de su aplicación. Utilice el modo de encendido retardado si necesita que un dispositivo se inicie después de un retraso, el modo de intervalo si el dispositivo debe funcionar durante un período específico y el modo de apagado retardado si el dispositivo debe apagarse después de un tiempo determinado. Considere la secuencia de operaciones y cómo se debe controlar cada dispositivo.

Potencie sus proyectos con PLC Omron, Mitsubishi y Schneider nuevos y originales: ¡en stock y listos ahora!

Conclusión

- Los temporizadores son dispositivos esenciales para controlar operaciones basadas en el tiempo en diversas aplicaciones, desde simples tareas domésticas hasta procesos industriales complejos.

- Hay dos tipos principales de temporizadores: analógicos y digitales, cada uno con su propio conjunto de características y beneficios.

- Comprender los diferentes modos de funcionamiento de los temporizadores, como el retardo de encendido, el intervalo y el retardo de apagado, es fundamental para seleccionar el temporizador adecuado para sus necesidades.

- Los temporizadores digitales ofrecen funciones avanzadas y capacidad de programación, lo que los hace ideales para la automatización industrial y los sistemas integrados.

- La configuración y el uso adecuados de los temporizadores pueden mejorar significativamente la eficiencia, la seguridad y la productividad en la fabricación y otros entornos industriales.

- Para elegir el temporizador adecuado hay que tener en cuenta factores como la precisión, el modo de funcionamiento y las condiciones ambientales.

Para obtener más ayuda y explorar cómo nuestros productos pueden mejorar sus procesos de automatización industrial, por favor Visita nuestro sitio web o Contacte con nuestro equipoPermítanos ayudarle a optimizar sus operaciones con el poder de la sincronización precisa.

Contáctenos

Simplemente complete su nombre, dirección de correo electrónico y una breve descripción de su consulta en este formulario. Nos comunicaremos con usted dentro de las 24 horas.

Categoría de producto

Productos en oferta

También te pueden interesar estos temas

¿Cómo controla un PLC una válvula solenoide?

Cuando se trata de controlar el flujo de fluidos, las válvulas solenoides son un componente crucial. Sin embargo, muchos ingenieros tienen dificultades para utilizarlas de manera eficaz en sus proyectos. Si se siente frustrado al controlar las válvulas solenoides, no está solo.

10 cosas que debes saber sobre los tipos de CPU de Omron

10 cosas que necesita saber sobre el tipo de CPU Omron Como ingeniero con años de experiencia en la industria

HMI vs. SCADA: Guía esencial para la automatización industrial

El sector de la automatización industrial ha sido testigo de una transformación revolucionaria, con tecnologías como HMI (interfaz hombre-máquina) y SCADA (control de supervisión y adquisición de datos) a la vanguardia. Estos sistemas permiten a las industrias supervisar, controlar y optimizar las operaciones, lo que garantiza una mayor eficiencia y productividad.