Все, что вам нужно знать о блоках питания PLC

В этом блоге мы рассмотрим типы ПЛК блоки питания, их функциональность и роль в современных системах автоматизации.

Оглавление

Что такое блок питания PLC?

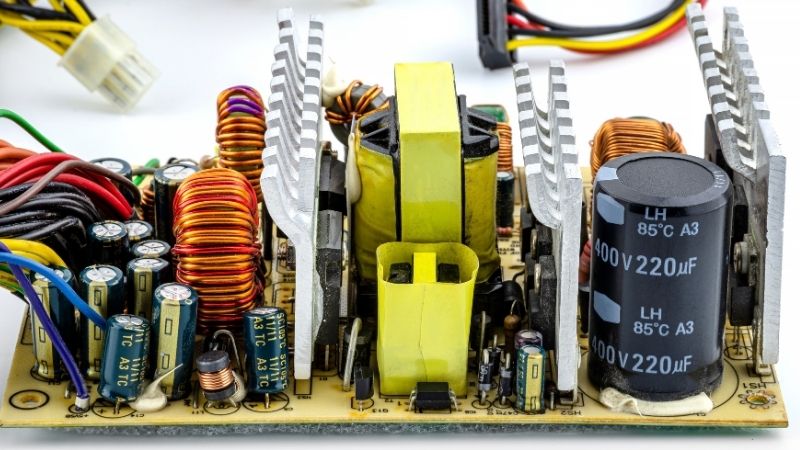

Блок питания PLC — это устройство или модуль, отвечающий за преобразование переменного тока высокого напряжения (AC) от основного источника питания в постоянный ток низкого напряжения (DC), подходящий для системы PLC. Обычно он понижает напряжение, выпрямляет его до постоянного тока и стабилизирует для постоянной подачи на PLC.

Большинство источников питания PLC обеспечивают стандартный выход 24 В постоянного тока, который питает не только ЦП, но и другие модули, подключенные к объединительной плате PLC. Кроме того, они могут включать встроенные функции, такие как защита от перегрузки по току и резервное питание от батареи, чтобы обеспечить надежность в критических системах.

Типы источников питания PLC

Источники питания PLC выпускаются в различных формах, каждая из которых соответствует определенным системным требованиям.

Встроенные блоки питания для небольших систем

Некоторые ПЛК меньшего размера, особенно компактные блоки с интегрированными точками ввода/вывода, поставляются со встроенными источниками питания. Они принимают вход переменного тока напрямую и преобразуют его в необходимое постоянное напряжение внутри.

- Преимущества: Простота установки и снижение потребности во внешних компонентах.

- Ограничения: Ограниченная выходная сила тока, что делает их пригодными только для небольших систем автоматизации.

Модульные блоки питания для больших систем

Более крупные ПЛК часто используют модульные блоки питания, прикрепленные к шасси или объединительной плате ПЛК. Такие блоки питания обеспечивают большую гибкость и более высокую выходную мощность.

- Преимущества: Возможность настройки в соответствии с системными требованиями.

- Ограничения: Более высокая стоимость и дополнительная сложность установки по сравнению со встроенными вариантами.

Как блоки питания PLC обеспечивают электропитание

Блок питания обычно обеспечивает питание ЦП и подключенных модулей через объединительную плату — внутреннюю шинную систему, которая распределяет энергию по всем компонентам.

- Для модульных ПЛК: Модуль питания подключается к шасси и подает питание на каждый модуль.

- Для встроенных ПЛК: Подача питания осуществляется изнутри, но для дополнительных полевых устройств может потребоваться внешняя проводка.

Выбор правильного источника питания ПЛК

Выбор правильного блока питания подразумевает понимание требований вашей системы. Рассмотрите следующие факторы:

- Входное напряжение: Обеспечьте совместимость с имеющимся переменным током (например, 120 В или 240 В).

- Выходное напряжение: Большинству ПЛК требуется 24 В постоянного тока, но проверьте спецификации.

- Текущий рейтинг: Сопоставьте выходной ток (в амперах) с потребляемой мощностью системы. Например, для небольших систем может потребоваться 2–10 ампер, а для более крупных систем — до 50 ампер.

Роль резервных батарей в источниках питания ПЛК

Многие блоки питания PLC включают в себя систему резервного питания. Эта функция поддерживает память и критические функции во время отключений питания, предотвращая потерю данных и простои в работе.

- Совет по обслуживанию аккумулятора: Регулярно проверяйте и заменяйте батареи ПЛК в рамках графика профилактического обслуживания.

Питание полевых устройств и ввода-вывода

Важно отметить, что блоки питания ПЛК обычно не обеспечивают питание полевых устройств, таких как датчики или приводы, напрямую. Эти устройства требуют отдельных источников питания постоянного тока.

- Лучшая практика: Используйте специальный блок питания постоянного тока, монтируемый на DIN-рейку, для подачи питания на модули ввода-вывода и обеспечения надлежащего замыкания цепи.

Обеспечьте свои проекты новыми, оригинальными ПЛК Omron, Mitsubishi, Schneider — в наличии, готовы прямо сейчас!

Заключение

Надежный источник питания ПЛК необходим для хорошо функционирующей системы автоматизации. Независимо от того, работаете ли вы с компактным ПЛК или модульной установкой, понимание типов источников питания, их функциональности и критериев выбора может уберечь вас от неожиданных сбоев.

Связаться с нами

Просто заполните свое имя, адрес электронной почты и краткое описание вашего запроса в этой форме. Мы свяжемся с вами в течение 24 часов.

Категория продукта

Горячие продажи товаров

Эти темы также могут быть вам интересны

Типы выходов ПЛК: основное руководство для инженеров по автоматизации

В мире промышленной автоматизации понимание типов выходов ПЛК имеет решающее значение для эффективного проектирования и внедрения системы управления. Это всеобъемлющее руководство проведет вас через различные типы выходов ПЛК, их применение и то, как выбрать правильный для ваших конкретных потребностей.

Что такое таймер в ПЛК и как он работает?

Что такое таймер в ПЛК и как он работает? В мире промышленной автоматизации время — это все.

6 ведущих производителей HMI в промышленной автоматизации

6 ведущих производителей HMI в промышленной автоматизации. Инженер в Kwoco с многолетним опытом работы в промышленной автоматизации