Interrupteurs de fin de course expliqués : types, utilisations et principes de fonctionnement

Cet article examine les types d'interrupteurs de fin de course, leur fonctionnement et pourquoi ils restent indispensables malgré l'essor de la proximité capteurs.

Table des matières

Que sont les interrupteurs de fin de course ?

Les interrupteurs de fin de course sont des dispositifs électromécaniques qui réagissent au contact physique. Lorsqu'un objet applique une force sur l'actionneur de l'interrupteur, il déclenche une connexion électrique qui se ferme ou se ferme.

Cette fonctionnalité permet aux interrupteurs de fin de course de détecter la position, le mouvement ou la présence d'un objet, permettant ainsi un contrôle précis au sein d'un système. Ces interrupteurs doivent leur nom au fait qu'ils étaient initialement utilisés pour définir la limite de déplacement d'un objet.

Types d'interrupteurs de fin de course

Il existe quatre principaux types d'interrupteurs de fin de course, chacun adapté à différentes applications en fonction de la forme et de la fonction de l'actionneur. Explorons ces types :

- Moustaches:L'actionneur ressemble à une moustache ou à un fil et convient aux applications de contact léger.

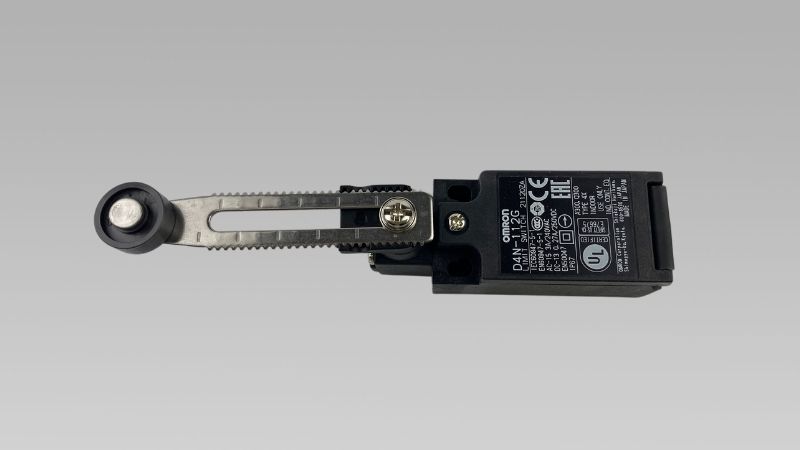

- Rouleau:Équipé d'un mécanisme de roulement, ce type est idéal pour les applications où les objets doivent rouler.

- Levier:Un type classique avec un actionneur à levier, couramment utilisé pour les applications à usage général.

- Piston:Ce type est doté d'un mécanisme de poussée directe et est couramment utilisé dans les applications lourdes.

Selon l'application, certains interrupteurs de fin de course peuvent combiner deux types, comme un interrupteur à levier à galet, pour répondre à des besoins spécifiques.

Applications des interrupteurs de fin de course

Les interrupteurs de fin de course sont partout, des objets ménagers courants aux machines industrielles. Voici quelques exemples courants :

- Portes de réfrigérateur:Lorsque vous ouvrez le réfrigérateur, un interrupteur de fin de course active la lumière intérieure, l'éteignant lorsque la porte se ferme.

- Portes de garage:Dans les portes de garage basculantes, les interrupteurs de fin de course garantissent que la porte s'arrête de bouger une fois qu'elle atteint la position complètement ouverte ou fermée.

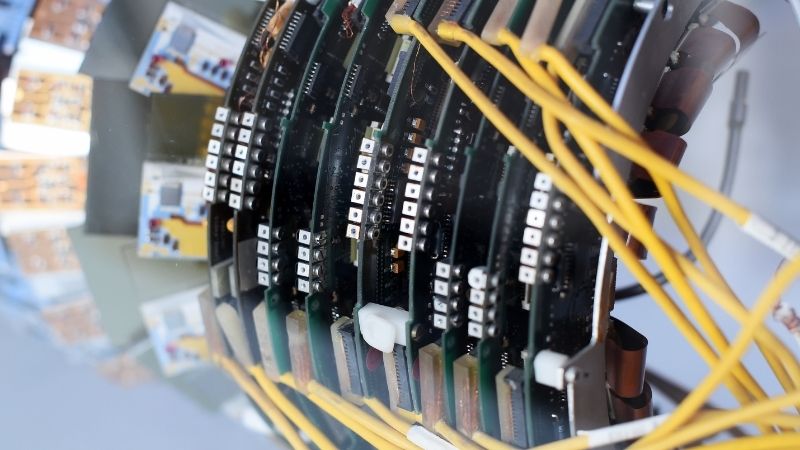

- Machines industrielles:Dans les usines, les interrupteurs de fin de course détectent la présence de conteneurs sur les lignes d'assemblage ou la position des pièces en mouvement, améliorant ainsi l'efficacité et la sécurité.

Comment fonctionnent les interrupteurs de fin de course ?

Un interrupteur de fin de course est constitué d'un actionneur relié mécaniquement à un interrupteur électrique. Lorsqu'un objet entre en contact avec l'actionneur, il provoque l'ouverture ou la fermeture du circuit par l'interrupteur, selon la configuration. Ce mécanisme permet un contrôle fiable et cohérent dans diverses applications, des simples commandes d'éclairage aux systèmes automatisés complexes.

Configurations des interrupteurs de fin de course

Les interrupteurs de fin de course sont disponibles dans plusieurs configurations, principalement :

- Normalement ouvert (NO):Le circuit est ouvert jusqu'à ce que l'interrupteur soit activé.

- Normalement fermé (NC):Le circuit est fermé jusqu'à ce que l'interrupteur soit activé.

- SPDT (unipolaire bidirectionnel):Une combinaison de configurations NO et NC, permettant un contrôle plus complexe.

Ces configurations offrent une flexibilité, permettant de personnaliser les interrupteurs de fin de course pour divers systèmes électriques et mécaniques.

Symboles des interrupteurs de fin de course

Dans les schémas électriques, différents symboles représentent les interrupteurs de fin de course, en fonction de la norme. Les deux principales normes pour les symboles des interrupteurs de fin de course sont les suivantes :

- CEI (Commission électrotechnique internationale):Une norme internationale largement utilisée.

- NEMA (Association nationale des fabricants d'équipements électriques):Une norme américaine couramment utilisée dans les applications nord-américaines.

La compréhension de ces symboles est essentielle pour interpréter les schémas électriques, en particulier dans les applications mondiales où les équipements peuvent suivre des normes différentes.

Capteurs de proximité et interrupteurs de fin de course

Bien que les capteurs de proximité soient devenus plus courants dans les environnements industriels, les interrupteurs de fin de course sont encore largement utilisés, en particulier dans les environnements qui exigent une durabilité. Contrairement aux interrupteurs de fin de course, les capteurs de proximité ne comportent aucune pièce mobile, ce qui réduit l'usure.

Cependant, les interrupteurs de fin de course sont très robustes et peuvent supporter des charges de courant plus élevées, ce qui les rend plus adaptés aux applications à forte contrainte. Dans les scénarios où la fiabilité dans des environnements difficiles est essentielle, les interrupteurs de fin de course restent le choix privilégié.

Alimentez vos projets avec des PLC Omron, Mitsubishi, Schneider flambant neufs et originaux – en stock, prêts maintenant !

Conclusion

Les interrupteurs de fin de course sont un composant indispensable dans diverses industries, offrant un contrôle fiable et précis dans des systèmes allant des appareils électroménagers aux machines industrielles.

Alors que les capteurs de proximité sont en plein essor, les interrupteurs de fin de course continuent de tenir bon grâce à leur robustesse et à leur adaptabilité. En comprenant les types, les configurations et les applications des interrupteurs de fin de course, vous pouvez prendre des décisions plus éclairées pour sélectionner la meilleure option pour votre application.

Vous recherchez des automates neufs et originaux pour vos projets ? Chez Kwoco, nous proposons les derniers automates des plus grandes marques telles que Omron, Mitsubishi, et SchneiderAchetez en toute confiance : expédition rapide, qualité garantie ! Achetez maintenant

Contactez-nous

Remplissez simplement votre nom, votre adresse e-mail et une brève description de votre demande dans ce formulaire. Nous vous contacterons dans les 24 heures.

Catégorie de produit

Produits en vente à chaud

Ces sujets pourraient également vous intéresser

Maîtriser Studio 5000 et RSLogix 5000 pour l'automatisation

Découvrez comment Studio 5000 Logix Designer et RSLogix 5000 révolutionnent l'automatisation industrielle. Ce guide instructif démystifie ces puissants outils, les rendant accessibles à tous, en particulier à ceux qui débutent dans la programmation PLC ou qui cherchent à améliorer leurs compétences.

Tout ce que vous devez savoir sur les composants du système pneumatique

Cet article offre un aperçu complet des systèmes pneumatiques, une technologie essentielle dans l'automatisation industrielle. Nous allons nous plonger dans les subtilités du fonctionnement de ces systèmes, leurs composants clés et leurs applications variées. La lecture de cet article vous permettra d'acquérir une compréhension approfondie de la pneumatique et des raisons pour lesquelles elle est indispensable dans le paysage technologique actuel.

Qu'est-ce qu'un servo et comment fonctionne-t-il ?

Une question que je reçois souvent de mes clients est : « Qu’est-ce qu’un servo exactement et comment fonctionne-t-il ? » Laissez-moi vous l’expliquer.

Les servomoteurs sont des composants essentiels de l'automatisation moderne. Ils assurent un contrôle précis du mouvement, ce qui est crucial dans de nombreuses applications industrielles.