Vollständige Anleitung zur Verkabelung und Fehlerbehebung bei fotoelektrischen Sensoren

Egal, ob Sie ein erfahrener Ingenieur oder ein Neuling in der Automatisierung sind, Sie erhalten wertvolle Einblicke, die sicherstellen, dass Ihre Sensoren zuverlässig und effizient arbeiten.

Inhaltsverzeichnis

Was sind fotoelektrische Sensoren und wie funktionieren sie?

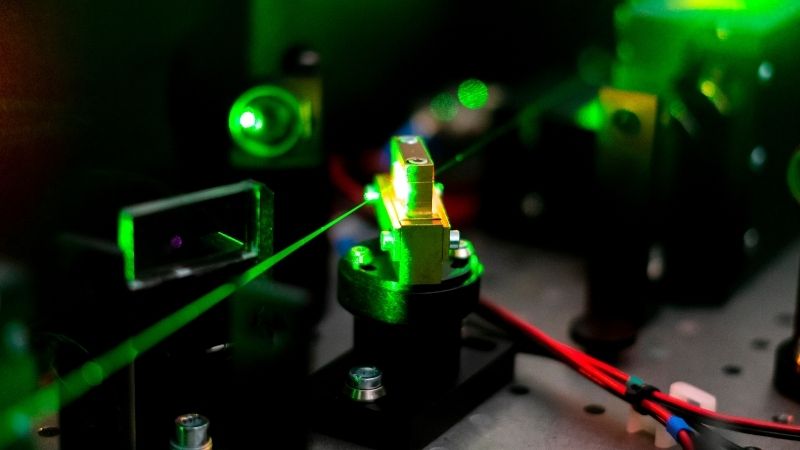

Photoelektrische Sensoren sind wesentliche Komponenten in modernen industriellen Automatisierungssystemen. Diese Geräte verwenden Lichtstrahlen, um Objekte zu erkennen und entsprechende Ausgänge auszulösen. Es gibt verschiedene Arten von photoelektrischen Sensoren:

- Einweglichtschranken: Bestehend aus separaten Sender- und Empfängereinheiten

- Reflexionslichtschranken: Verwenden Sie einen Reflektor, um den Lichtstrahl zurückzuwerfen

- Lichttaster: Objekte anhand direkter Reflexion erkennen

Die Wahl des Sensortyps hängt von Ihren spezifischen Anwendungsanforderungen, der Erfassungsreichweite und den Umgebungsbedingungen ab.Erfahren Sie mehr über Industriesensoren

Wichtige Schritte zur ordnungsgemäßen Verkabelung fotoelektrischer Sensoren

Die korrekte Verdrahtung ist für eine zuverlässige Sensorfunktion von entscheidender Bedeutung. Hier ist eine detaillierte Aufschlüsselung des Verdrahtungsprozesses:

- Stromanschluss

- Verbinden Sie das braune Kabel mit dem 24-Volt-DC-Pluspol.

- Verbinden Sie das blaue Kabel mit dem 24-Volt-DC-Minuspol

- Ausgangsverdrahtung

- Schwarzes Kabel: Ausgangssignal zum SPS-Eingang

- Weißes Kabel: Zusätzlicher Ausgang (für Modelle mit komplementärem Ausgang)

„Die richtige Farbcodierung und Verbindungsüberprüfung sind wesentliche Schritte zur Vermeidung von Verdrahtungsproblemen.“ – Experte für industrielle Automatisierung

Wie konfigurieren und richten Sie Ihren fotoelektrischen Sensor ein?

Die richtige Einrichtung gewährleistet eine optimale Sensorleistung. Befolgen Sie diese Konfigurationsschritte:

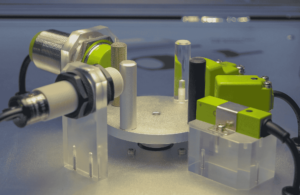

- Montage und Ausrichtung

- Sichere Befestigung von Sensor und Reflektor/Empfänger an stabilen Halterungen

- Stellen Sie die richtige Ausrichtung zwischen den Komponenten sicher

- Empfohlene Erfassungsreichweite einhalten

- Empfindlichkeitseinstellung

- Mit dem Potentiometer lässt sich die Empfindlichkeit einstellen

- Testen Sie die Erkennung mit tatsächlichen Zielobjekten

- Überprüfen Sie, ob die Kontrollleuchten richtig funktionieren

Häufige Probleme und Lösungen bei der Fehlerbehebung

| Ausgabe | Mögliche Ursache | Lösung |

|---|---|---|

| Kein Ausgangssignal | Falsche Verdrahtung | Überprüfen der Kabelverbindungen |

| Falsche Auslöser | Empfindlichkeit zu hoch | Potentiometer einstellen |

| Inkonsistente Erkennung | Schlechte Ausrichtung | Sensorkomponenten neu ausrichten |

| Kein Strom | Fehlerhafte Stromversorgung | Überprüfen Sie die Spannungspegel |

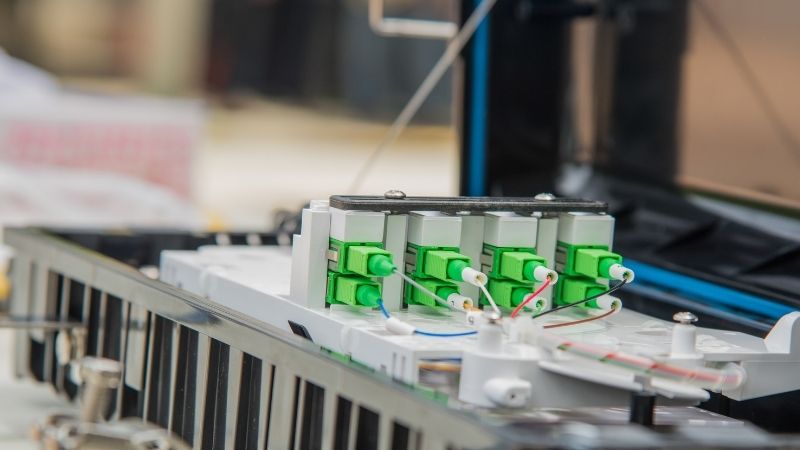

Integration mit SPS und Steuerungssystemen

Moderne fotoelektrische Sensoren lassen sich nahtlos in speicherprogrammierbare Steuerungen (SPS) und andere Steuerungssysteme integrieren. Wichtige Aspekte sind:

- Kompatibilität der Eingangs-/Ausgangssignale

- Anforderungen an die Reaktionszeit

- Kommunikationsprotokolle

- Systemkonfiguration

Häufig gestellte Fragen

Beginnen Sie mit mittlerer Empfindlichkeit und passen Sie diese basierend auf den Eigenschaften des Zielobjekts und den Umgebungsbedingungen an

Die Reichweite variiert je nach Modell, reicht aber normalerweise von einigen Metern bis zu über 20 Metern

Verwenden Sie die richtigen Empfindlichkeitseinstellungen, achten Sie auf saubere Optik und sorgen Sie für eine stabile Montage

Möglicherweise sind spezielle Modelle für die Erkennung transparenter Objekte erforderlich.

Es wird empfohlen, die optischen Oberflächen regelmäßig zu reinigen und die Ausrichtung periodisch zu überprüfen.

Versorgen Sie Ihre Projekte mit brandneuen, originalen Sensoren von Omron, Keyence und Schneider – auf Lager, sofort verfügbar!

Abschluss

- Überprüfen Sie immer die korrekte Spannung und die korrekten Kabelverbindungen

- Die richtige Montage und Ausrichtung sind entscheidend für einen zuverlässigen Betrieb

- Regelmäßige Wartung sichert gleichbleibende Leistung

- Wählen Sie den richtigen Sensortyp für Ihre Anwendung

- Dokumentieren Sie die Konfigurationseinstellungen zur späteren Bezugnahme

- Halten Sie optische Oberflächen sauber und geschützt

- Berücksichtigen Sie Umgebungsfaktoren bei der Sensorauswahl

Holen Sie sich Expertenunterstützung für Ihre Automatisierungsanforderungen

Suchen Sie nach neuen, originalen Sensoren für Ihre Projekte? Bei Kwoco führen wir die neuesten Sensoren von Top-Marken wie Omron, Keyence, Und Schneider. Kaufen Sie vertrauensvoll ein – schneller Versand, garantierte Qualität! Jetzt kaufen

Kontaktieren Sie uns

Geben Sie in dieses Formular einfach Ihren Namen, Ihre E-Mail-Adresse und eine kurze Beschreibung Ihrer Anfrage ein. Wir werden Sie innerhalb von 24 Stunden kontaktieren.

Diese Themen könnten Sie auch interessieren

Induktive 3-Leiter-Näherungssensoren: Vollständige Anleitung

Möchten Sie verstehen, wie induktive 3-Leiter-Näherungssensoren in der industriellen Automatisierung funktionieren? Diese unverzichtbaren Sensorgeräte haben moderne Fertigungsprozesse revolutioniert, indem sie eine zuverlässige, berührungslose Erkennung metallischer Objekte ermöglichen.

Servomotor vs. normaler Motor: Wichtige Unterschiede erklärt

Eine häufig gestellte Frage lautet: „Was ist der Hauptunterschied zwischen einem Servomotor und einem normalen Motor?“ Das Verständnis dieses Unterschieds ist für jeden von entscheidender Bedeutung, der den richtigen Motor für seine Anwendung auswählen möchte.

Fehlerbehebung bei Mitsubishi Servo: Beheben des AL16-Treiberalarms

Fehlerbehebung bei Mitsubishi Servo: Behebung des AL16-Treiberalarms Mitsubishi Servosysteme sind für ihre Zuverlässigkeit und Präzision bekannt und werden häufig eingesetzt