Что вам нужно знать о цифровых и аналоговых входах в ПЛК

- kwoco-plc.com

- 24 сентября 2024 г.

- 2:15 дп

Вы когда-нибудь задумывались, как ваши промышленные системы автоматизации взаимодействуют с реальным миром? Понимание разницы между цифровыми и аналоговыми входами в программируемых логических контроллерах (ПЛК) имеет решающее значение. Это может повысить или понизить эффективность ваших инженерных проектов.

Цифровые входы являются двоичными и представляют собой состояния «включено/выключено», тогда как аналоговые входы обеспечивают непрерывные данные, что обеспечивает более широкий диапазон управления.

В мире промышленной автоматизации важна каждая деталь. Как инженер в Kwoco, я своими глазами видел, как эти входы влияют на производительность и надежность системы. Если вы отвечаете за поставку компонентов ПЛК или управление инженерными проектами, эта информация жизненно важна.

Оглавление

Что такое цифровые и аналоговые входы?

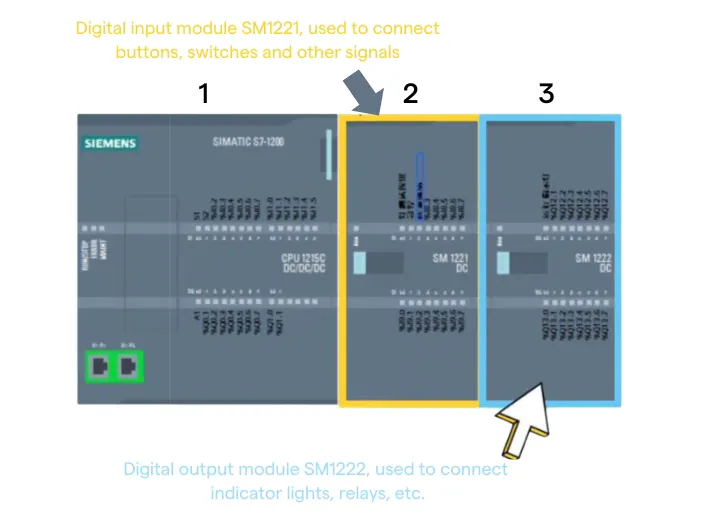

Цифровые входы предназначены для распознавания двух различных состояний: высокого (1) и низкого (0). Они обычно используются для устройств, которые работают в двоичном режиме, таких как концевые выключатели, кнопки и релеЦифровые сигналы позволяют легко определить, активно ли устройство или нет.

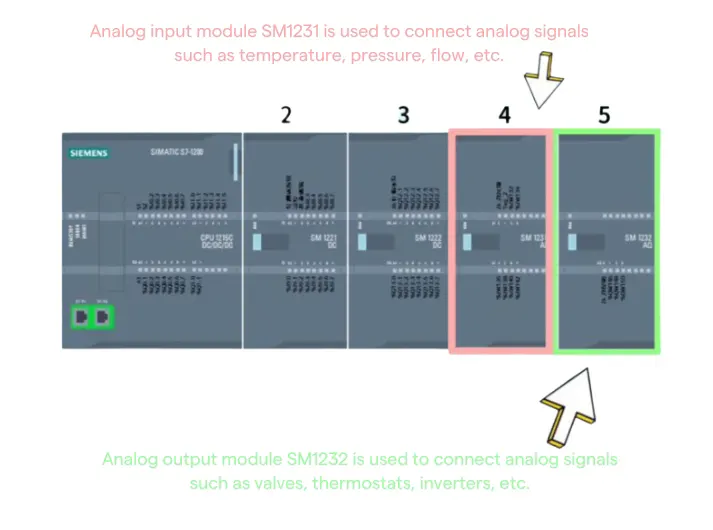

С другой стороны, аналоговые входы могут обрабатывать ряд значений, что делает их подходящими для таких устройств, как датчики температуры, преобразователи давления и расходомеры. Эти входы преобразуют явления реального мира в данные, которые могут понимать ПЛК, что позволяет осуществлять точный контроль над процессами.

Почему это важно?

Выбор между цифровыми и аналоговыми входами может существенно повлиять на результаты вашего проекта. Понимание их сильных сторон поможет вам принимать обоснованные решения в процессе закупок.

Например, если вы курируете проект, требующий мониторинга данных в реальном времени, аналоговые входы могут быть лучшим выбором. И наоборот, для простых элементов управления включением/выключением цифровых входов более чем достаточно.

В этой статье мы подробнее рассмотрим характеристики, области применения и преимущества каждого типа входных данных.

Как цифровые входы используются в автоматизации?

Цифровые входы играют важную роль в промышленной автоматизации. Они широко используются для управления машинами, мониторинга систем безопасности и выполнения базовых функций.

Например, рассмотрим упаковочную линию, где датчик определяет наличие коробки. Этот датчик генерирует цифровой сигнал, который ПЛК интерпретирует для запуска или остановки конвейерной ленты. Такие приложения подчеркивают простоту и надежность цифровых входов.

А как насчет аналоговых входов?

Аналоговые входы предлагают уровень сложности, с которым цифровые входы не могут сравниться. Они необходимы в приложениях, где условия постоянно меняются.

Возьмите контроль температуры в производственном процессе. Аналоговый датчик температуры передает данные в реальном времени на ПЛК, позволяя ему точно регулировать нагревательные элементы. Такой уровень контроля может значительно повысить качество продукции и энергоэффективность.

В чем основные отличия?

Вот некоторые важные различия между цифровыми и аналоговыми входами:

- Тип сигнала: Цифровые входы являются двоичными, а аналоговые входы — непрерывными.

- Сложность: Цифровые системы проще и легче в устранении неполадок. Аналоговые системы требуют более сложной проводки и конфигурации.

- Диапазон данных: Цифровые входы ограничены двумя состояниями, тогда как аналоговые входы могут представлять широкий диапазон значений.

- Приложения: Цифровые входы идеально подходят для управления включением/выключением, в то время как аналоговые входы отлично подходят для измерения переменных, которые изменяются со временем.

Какой из них выбрать?

Решение об использовании цифровых или аналоговых входов зависит от вашего конкретного приложения. Вот несколько наводящих вопросов, которые помогут вам определить лучший вариант:

- Какие типы сигналов должна обрабатывать ваша система?

- Имеете ли вы дело с бинарными состояниями или непрерывными измерениями?

- Насколько важна точность в вашем приложении?

- Какие устройства вы будете интегрировать в свой ПЛК?

- Вам требуется обратная связь по данным в режиме реального времени?

- Каковы ваши бюджетные ограничения?

Ответив на эти вопросы, вы сможете лучше выбрать правильный тип входных данных для своего инженерного проекта.

Проблема интеграции

Интеграция цифровых и аналоговых входов может быть сложной задачей. Многие ПЛК предлагают оба типа входов, но конфигурация может потребовать определенных знаний.

Правильная калибровка аналоговых датчиков имеет важное значение для обеспечения точных показаний. Если калибровка не выполнена правильно, вы рискуете получить ошибочные данные, что может привести к принятию неверных решений.

Для цифровых входов решающее значение имеют проводка и целостность сигнала. Неправильные соединения могут привести к прерывистым сигналам, что приведет к неправильной работе оборудования.

Обеспечьте свои проекты новыми, оригинальными ПЛК Omron, Mitsubishi, Schneider — в наличии, готовы прямо сейчас!

Реальные приложения

В реальных условиях цифровые и аналоговые входы часто используются вместе для создания комплексной системы управления. Например, водоочистное сооружение может использовать цифровые входы для мониторинга насосов, а аналоговые входы — для измерения параметров качества воды, таких как pH и мутность.

Эта интеграция позволяет создать отзывчивую и адаптируемую систему. Она может корректировать процесс лечения на основе данных в реальном времени, что приводит к улучшению результатов.

Потенциальные ловушки, которых следует избегать

Хотя и цифровые, и аналоговые входы имеют свои преимущества, существуют распространенные недостатки, на которые следует обратить внимание:

- Игнорирование совместимости: Не все датчики совместимы с каждым ПЛК. Всегда проверяйте спецификации.

- Пренебрежение техническим обслуживанием: Регулярные проверки аналоговых датчиков имеют решающее значение для точности.

- Чрезмерное усложнение систем: Иногда простые решения (например, использование цифровых входов) позволяют достичь желаемых результатов без дополнительных сложностей.

Заключение

С этими знаниями в вашем наборе инструментов вы готовы принимать лучшие решения для ваших инженерных проектов. Если у вас есть какие-либо вопросы или вам нужна поддержка в выборе правильных компонентов, не стесняйтесь обращаться к нам. В Kwoco ([email protected]) мы здесь, чтобы помочь вам достичь ваших целей автоматизации.

Связаться с нами

Просто заполните свое имя, адрес электронной почты и краткое описание вашего запроса в этой форме. Мы свяжемся с вами в течение 24 часов.

Почему вашему ПЛК нужен отдельный источник питания

Почему вашему ПЛК нужен отдельный источник питания Вы когда-нибудь задумывались, почему системам ПЛК часто требуется отдельный источник питания?

Почему вашему бизнесу нужен частотно-регулируемый привод

Почему вашему бизнесу нужен частотно-регулируемый привод При управлении промышленными операциями решающее значение имеет оптимизация энергоэффективности при сохранении производительности.

Почему изоляция сигнала имеет решающее значение для ПЛК Omron?

Почему изоляция сигнала имеет решающее значение для ПЛК Omron? В мире промышленной автоматизации помехи сигнала являются тихим убийцей.